about us

YUCO MOLD provides professional one-stop service for injection molding. Our mission is to provide our customers with persistent innovation and tailor-made services.

Leading injection mold supplier

Located in the heart of Huangyan, Taizhou, the mold capital of China, YUCO MOLD is a model of excellence in the plastic injection molding industry.

With over a decade of professional experience, the company specialises in the design and manufacture of the highest quality injection molds. Our expertise is not only limited to manufacturing, but we are also committed to providing tailor-made one-stop service solutions to meet the unique needs of our customers.

We have more than 100 employees, 20 senior technicians and 6 engineers. The factory mainly designs and produces various household product molds, industrial product molds, and daily necessities injection molds.

At YUCO MOLD, we don't just make molds, we build lasting partnerships that deliver value and innovation through our bespoke services. We have more than 10 years overseas sales experience in more than 20 countries.

Our capability

- Strength factory with many fine equipments

- Customized mold design

- Perfect quality management system

- Senior engineers with more than 10 years experience

- One-stop service from design to molding

Mold manufacturing process

YUCO MOLD's project managers pay strict attention to detail at every manufacturing step to ensure that our customers receive only the highest quality custom mold solutions.

01

Customization

02

Mold design

03

Mold manufacturing

04

Mold inspection

05

Mold testing

06

Packing & Shipping

Customization

Customers can share their specific requirements with our project managers. We will conduct a thorough manufacturing feasibility analysis to ensure that your idea is both visionary and practical.

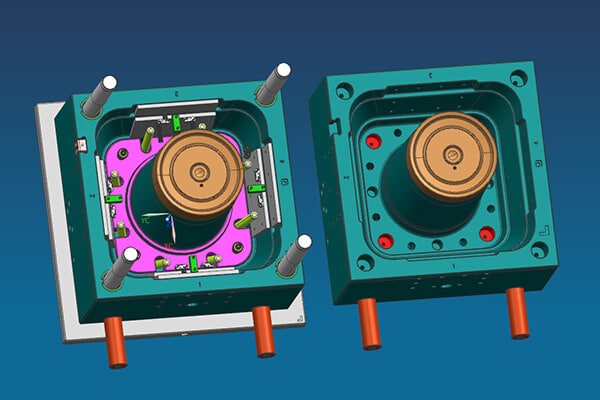

Mold design

YUCO's highly skilled engineers utilise advanced CAD, CAM and CAE software to provide customers with practical design solutions.

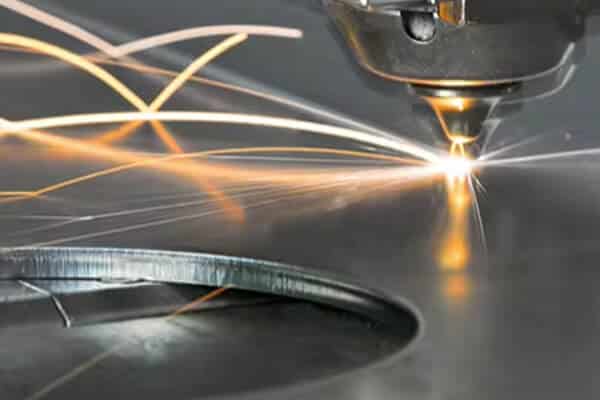

Mold manufacturing

YUCO MOLD owns high-speed EDM, EDM mirror spark machine, CNC machining centre and other excellent equipments to ensure the production of high quality moulds.

Mold inspection

YUCO MOLD adopts strict inspection procedures, including First Article Inspection (FAI) and Coordinate Measuring Machine (CMM) inspection with full size inspection report.

Mold testing

We will carry out high pressure injection test and long time injection test on the moulds. The whole mould testing process will end up with a detailed mould testing report to provide assurance to our customers.

Packaging and shipping

YUCO MOLD provides comprehensive shipping lists and packaging reports to ensure your moulds are delivered safely and efficiently, ready for production.

YUCO MOLD's core equipments

Our factory is equipped with a full range of machining technologies and advanced equipment. This ensures that every mold project meets the highest standards of quality and workmanship. We have 10 sets of CNC machining equipment, and more than 2 sets of hardness testing, EDM, CMM and other equipment. And adopt advanced CAD/CAM/CAE process design, which enables us to develop large-volume, complex, deep cavity, thin-walled, and precise molds.

High-speed EDM

High speed milling

Driller

Coordinate measuring machine

Boring machine

Drilled hole

CNC machine

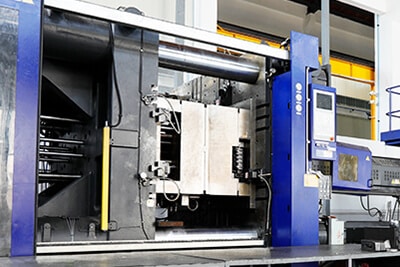

Injection molding machine

Mold flow analysis

YUCO MOLD provides you with a complete mold flow analysis report. The mold flow report accurately identifies potential problems that may arise during the actual mold testing.We can then make improvements in the design and manufacture of the mold.We can then improve and optimise the design and manufacture of the mold.

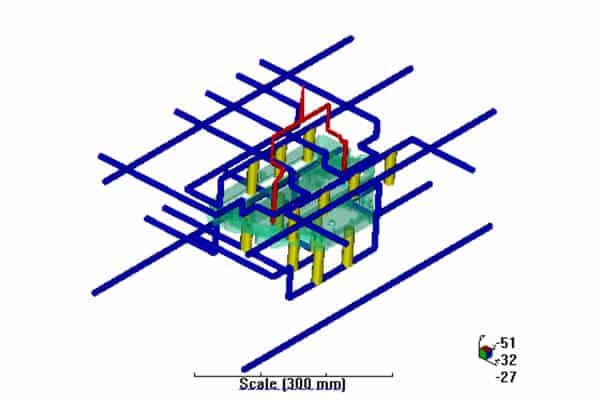

Cooling system design

This drawing shows the original design of the cooling system with 10 waterways.

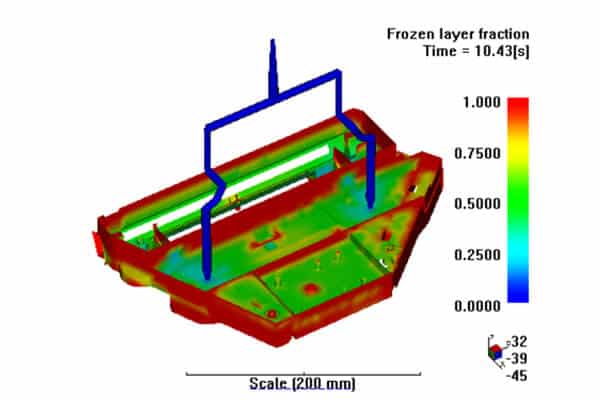

Cooling solidification process

The cooling and solidification process of a plastic product, with the red areas indicating the first areas to solidify.

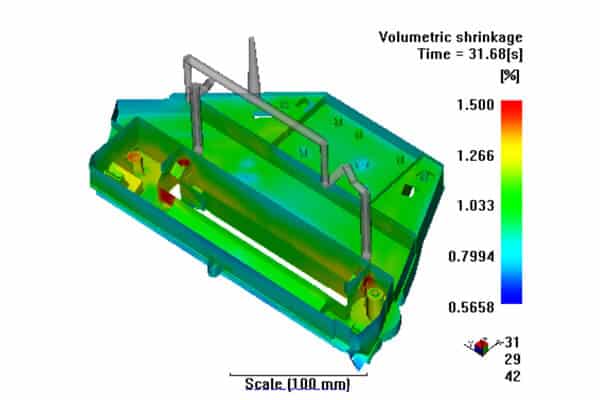

Volume shrinkage distribution

Shrinkage is more uniform in most areas, with larger shrinkage in the red areas.

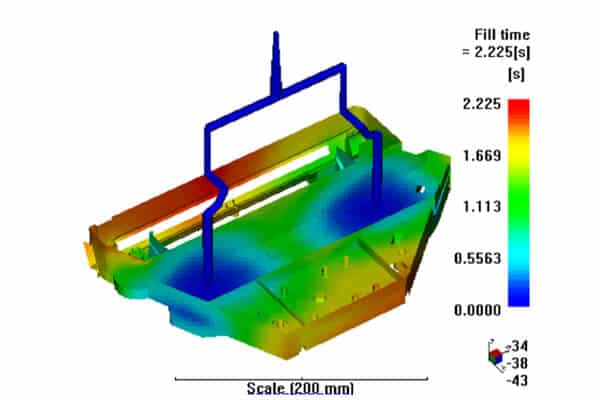

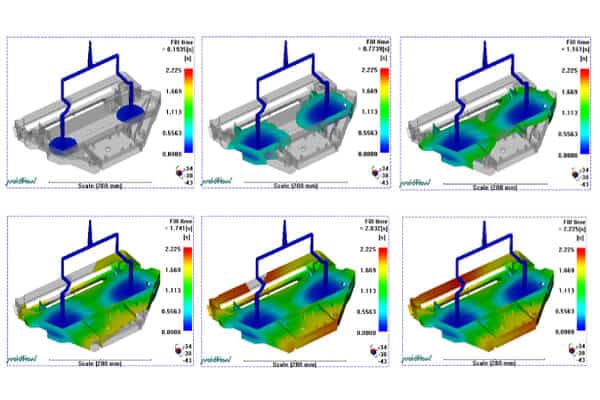

Filling time

Through mold flow analysis, we can simulate the approximate time of the plastic filling flow process.

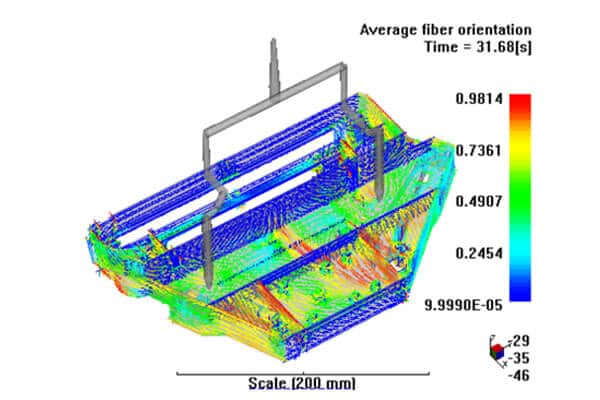

Average fiber orientation

The figure shows the wave fibre orientation from the beginning of the cycle to the opening of the mold.

Filling flow process

The whole filling flow process is highly reproducible to the whole process of plastic flow in the actual test mold.

Our histories

YOCO MOLD has always been at the forefront of the mold making industry. From its humble beginnings in 2010 to its current status as a leader in its field, YOCO MOLD's journey is a testament to the power of bespoke service and commitment to quality.

YOCO MOLD's history began in 2010 with a focus on precision, efficiency and customer satisfaction, laying the foundation for further expansion.

By 2012, YOCO MOLD had grown rapidly. The company expanded its services to include a wider range of CNC milling and EDM capabilities.

2015 was a watershed year for YOCO MOLD, which introduced a high-tight CNC machine in response to the growing demand for more sophisticated and complex mold designs.

Between 2016 and 2018, the Company continued to improve its skills, processes and technology to further enhance the quality of its injection molds.

The year 2020 was an important milestone in the history of YOCO MOLD as the company moved to a new state-of-the-art factory, equipped with the latest machinery and technology.

Since 2024, YOCO MOLD has been on a mission to provide customers with continuous innovation and tailor-made services, offering you a better one-stop injection molding service.

Frequently Asked Questions

What kinds of molds does YUCO Mold mainly produce?

YUCO Mold is a first-class plastic mold manufacturer in China. We provide complete mold manufacturing solutions to our customers. We mainly focus on daily use molds, but of course we also have transportation molds such as crate molds.

Does YUCO Mold protect customers' trade secrets?

Of course we do. We always sign a confidentiality agreement with our customers before we work together. Because we know that it is a trade secret and it is very important for the user.

Does YUCO Mold provide injection molding services?

Absolutely. We are committed to providing one-stop plastic injection molding services to our customers. We have not only CNC centres but also plastic molding machines in our factory. If you have a product that needs to be injection molded in China, we would be happy to help you.

Why is the cost of injection molding so high?

The price of a mold is made up of many factors. In general, with the exception of standard molds, customised molds can take anywhere from a few weeks to a few months to complete, depending on the complexity and size of the final product. In addition, the manufacture of molds requires the use of expensive software, CNC machinery, tooling and precision fixtures, all of which contribute to the high price of molds.

How should I maintain my mold?

When our mold leaves the factory, they will be equipped with mold maintenance instructions for you. Each mold has its maintenance methods, and we will introduce the conventional methods below.

- The mold must be kept clean and dry after use.

- You should also check them regularly for any signs of damage or wear. If you notice any cracks or chips in the mold, it will be necessary to replace them to prevent any contamination.

- You are using the correct tools and materials when handling and cleaning the mold. Avoid abrasive tools or harsh cleaners that may damage the mold. Instead, use a soft brush and mild detergent to keep them in good shape.

- Proper storage is also important to prevent deformation, so be sure to store the mold in a dry and cool place.

By following these steps, you can extend the life of your mold and maintain its quality over time.

What is the minimum order quantity offered by YUCO Mold?

One of the most frequently asked questions by our customers is about their minimum order quantity requirements. YUCO Mold has a flexible MOQ policy, which can meet both small and large quantities of orders. Even with smaller orders, we are always happy to discuss individual production needs and develop solutions.

Our Business

YUCO Mold has a history of dealing with business owners from many parts of the world, namely, the United States, London, Brazil, Russia, South Africa, South Korea, India, Morocco, and many more countries.