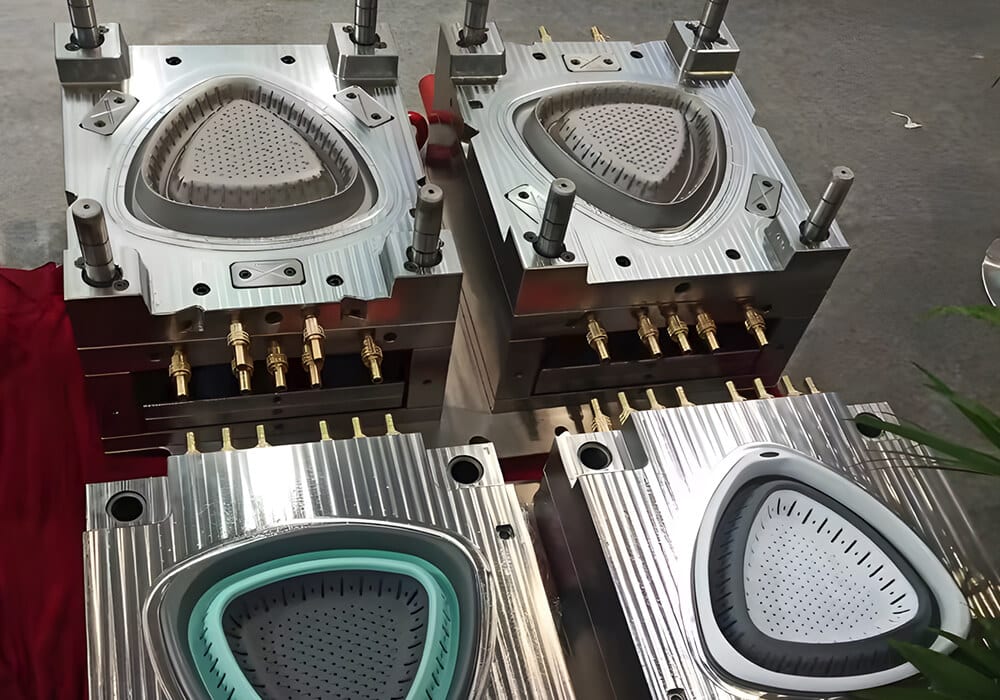

collapsible basket mold

YUCO MOLD is a China high-quality basket mold manufacturer, we manufacture all kinds of plastic Collapsible basket molds. We believe that spending an extra 10 minutes on design can save a month of mold production time.

Plastic collapsible basket molds from China manufacturer

- We strictly control quality, time, and cost to achieve a win-win situation. All basket mold designs are double-checked with the customer before processing, ensuring that 95% of molds pass the test on the first try.

- To ensure mold quality, we also conduct mold strength analysis, mold flow analysis, and the rationality of the mold ejection, cooling, and guide systems. We also document the specifications of the mold spare parts, consider the customer's machine selection, and implement special requirements.

- To reduce cycle time and save costs, we must optimize cooling. For collapsible basket molds, we utilize an excellent cooling channel design within the molding area.

- If you are considering purchasing an injection molding machine for baskets, we recommend a high-speed machine with a screw speed greater than 350 mm/min.

- Hot runner systems are crucial for both large and lightweight baskets. They ensure even filling of the plastic material.

collapsible basket mold specifications

| Specification Category | Details |

|---|---|

| Material Capabilities | • High-grade P20/718/738H/H13/S136/NAK80 tool steel • Hardness: 48-52 HRC • Heat treatment capability: Nitriding, QPQ treatment • Mirror polishing up to Ra 0.01μm |

| Technical Parameters | • Mould size range: 300×300mm-1500×1500mm • Weight capacity: Up to 30 tons • Cavity number: Single to 4-cavity options • Wall thickness: Down to 0.45mm • Collapse ratio: Up to 3:1 • Precision tolerance: ±0.01mm |

| Advanced Features | • Automated collapsible core mechanisms • Hot/cold runner systems available • Balanced runner design • Sequential valve gate control • Conformal cooling channels • Mould flow analysis optimization |

| Production Capabilities | • Annual capacity: 500+ sets • Rapid prototyping: 10-15 days • Full production mould: 25-45 days • 24/7 production facility • 50,000+ shots mould lifespan guarantee |

| Quality Control System | • 100% CMM inspection • 3D scanning verification • ISO 9001:2015 certified processes • In-mold sensors for quality monitoring • Trial injection service with inspection reports |

| Design Capabilities | • Full 3D design with SOLIDWORKS/UG/Pro-E • Reverse engineering capability • Design for Manufacture optimization • Simulation-driven design process • CAE analysis for structural integrity |

| Certifications | • ISO 9001:2015 Quality Management • ISO 14001:2015 Environmental Management • CE Certification for European market • FDA material compliance for food containers |

| After-Sales Service | • 2-year mold warranty • 24-hour technical response • Remote troubleshooting capability • Spare parts guaranteed for 10 years • Free mold maintenance training |

| Special Advantages | • Proprietary anti-wear coating technology • Patented quick-collapse mechanism • Energy-efficient mold design • Stackable basket design expertise • Customized texture and surface finishing |

China basket mold manufacturer

collapsible basket mold processing

This two-tone 2K collapsible plastic basket features a compact design for easy storage and transport. It’s ideal for those with limited space or those who need to carry a basket with them. It folds up in about 20-30 seconds without any tools.

The collapsible basket features dual comfort handles, making it easy to carry even when fully loaded. The comfortable grip and secure hold make it easy to move the basket from one location to another.

Why choose us as your partner?

Professional

Instant quotes

Customization

Reliable

On-time delivery

Dimensionally accurate

How to choose a collapsible basket mold ?

YUCO is committed to providing customers with high-quality collapsible basket molds and products, along with satisfactory service, through innovation, customer-centricity, and continuous improvement.

concept cesign

We employ state-of-the-art methods and a customer-centric approach to strategically position your product in the market. We match colors and textures to geometric shapes for a uniform and eye-catching result.

Developing collapsible baskets

You can provide 2D or 3D drawings or send us samples directly. We’ll scan the samples, create a 3D model of the product, and then design the mold drawings.

We can use Unigraphics, SolidWorks, AutoCAD, and Pro/ENGINEER for mold production. We emphasize the importance of input from experience to achieve functional and viable molded products.

collapsible basket mold design

We provide innovative technical solutions for mold design and implement them with a highly skilled team and state-of-the-art IT resources. Using our injection molding software, we can create designs and transform them into precise molds, precisely meeting your folding basket shape and texture requirements.

During the design process for plastic injection molded collapsible baskets, we focus on the mold cycle, parting line, wall thickness, venting, and other processes. By combining gas-assisted molding with computer-controlled automatic mold change and insertion, we continuously refine and develop mature technical knowledge and experience in collapsible basket production.

Mold manufacturing

For all molds, high-speed operation relies on precision machining and precise guides for the moving parts. Otherwise, the high-speed performance of collapsible basket molds is impossible.

We do not use manual machining, and instead heat-treat the mold steel to the correct hardness. Furthermore, our high-speed CNC machine tools achieve an accuracy of 0.02 mm.

Mold steel recommendations

When manufacturing a mold, it’s important to select high-quality mold steel for the mold base and the main mold steel (i.e., the cavity and core), and high-toughness steel for some inserts. Choosing the right steel ensures the durability of mold components.

Not all molds are suitable for high hardness, as excessive hardness can lead to fracture. Choosing the right hardness is the best choice.

- Generally, we recommend using S45c steel for the mold base and 718H nitriding for the core, cavity, and slide. This provides a mold life of at least one million cycles.

- If the mold base is made of S45c steel and the core, cavity, and slide are nitrided with P20, the product can be produced up to 500,000 times.

- For quantities under 200,000 pieces, all standard steels can also be heat treated.

Pre-production collapsible basket mold maintenance

The lifespan and performance of collapsible basket molds depend on proper maintenance. Following these guidelines will help extend the life of your collapsible basket mold.

- Clean the mold surface from oil and rust, and inspect the mold cooling holes for foreign matter.

- Inspect the gate for residual material.

- Inspect the fixed platen to confirm that the screw clamps are tightened.

- After securing the basket mold to the injection molding machine, perform the injection molding operation.

- Observe the movement of each component: for any abnormalities, wear on moving parts such as guide pins, ejector pins, and slides, proper lubrication, and stroke…

- The mold’s precision and usability depend, in part, on lubrication and calibration.

Let us work together to create a better future.

YUCO MOLD specializes in producing various basket molds. We have established a comprehensive process management system (ISO 9001 certified) to strictly control the quality of our products and services. We will always provide professional advice, strict management, and high-quality service.

If you are looking for collapsible basket molds or other basket molds, we are your ideal choice. We are confident that you will be satisfied with our plastic molds, molding solutions, and services. Please contact us for a quote on a custom injection mold.

Tel: +86 13586040750