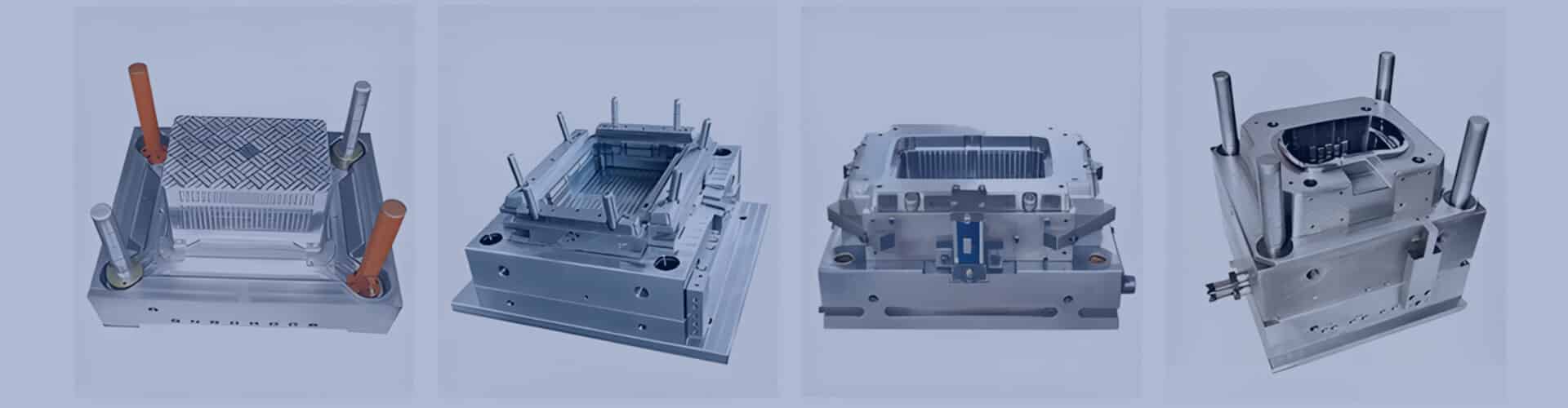

fruit basket mold

YUCO Mold is a Chinese plastic fruit basket mold manufacturer and custom fruit basket factory. We guarantee that our molds produce flawless, high-quality baskets.

Plastic fruit basket molds from China manufacturer

- Our company is equipped with high-tech equipment and state-of-the-art CAD/CAE/CAM systems. Our design team strives to maximize the aesthetic value of our products while maintaining excellent mold quality and design. Our experienced technicians rigorously maintain and operate every production process.

- YUCO Mold consistently manufactures high-quality, standard-compliant plastic molds, providing more suitable and stable mold structures that are easier to operate and maintain.

- Our molds are highly beneficial to fruit basket suppliers and manufacturers, producing sturdy and durable baskets.

fruit basket mold specifications

| Category | Specification | Details |

|---|---|---|

| Mould Material | Steel Types | H13, P20, 718H, S136, 2738, NAK80, 8407 premium steel |

| Steel Hardness | 48-52 HRC for cavity, 28-32 HRC for mold base | |

| Corrosion Resistance | High-grade stainless steel options for food-grade applications | |

| Mould Specifications | Size Range | Small (100×100×50mm) to Large (800×600×400mm) |

| Cavity Options | Single to 24-cavity molds | |

| Weight | 0.5 tons to 5 tons | |

| Lifespan | 500,000 to 1,000,000+ shots | |

| Technical Capabilities | Mould Type | Injection mould |

| Wall Thickness | Ultra-thin 0.4mm to standard 2.5mm | |

| Gate Systems | Hot runner, cold runner, submarine, direct, pin-point | |

| Cooling System | Conformal cooling channels, Baffle system, Bubbler system | |

| Production Parameters | Cycle Time | 15-45 seconds depending on complexity |

| Clamping Force | 80T to 1300T machines available | |

| Production Capacity | Up to 50 sets of molds per month | |

| Lead Time | 25-45 days for new molds | |

| Design Capabilities | 3D Design | Solidworks, UG, Pro-E, AutoCAD |

| Mould Flow Analysis | Advanced simulation for optimal filling, cooling | |

| Surface Finishes | Mirror, textured, matte, glossy, leather grain | |

| Complex Features | Undercuts, side-actions, collapsible cores | |

| Quality Control | Inspection Equipment | CMM, profile projector, 3D scanner, laser measuring |

| Testing Standards | PPAP, FAI, dimensional testing, material testing | |

| Certifications | ISO 9001, ISO 14001, ISO 45001 | |

| Quality System | 100% inspection before delivery, SPC, APQP | |

| Material Compatibility | Plastic Types | PP, PE, PC, ABS, HIPS, PET, PVC, PMMA, PA |

| Bio-Materials | PLA, PBS, starch-based composites | |

| Special Requirements | Food-grade certification, BPA-free | |

| Additional Services | Mold Modifications | Free minor adjustments within warranty period |

| Design Optimization | Weight reduction, structural reinforcement | |

| After-sales Support | 24/7 technical support, maintenance guidance | |

| Trial Production | Sample runs prior to mass production | |

| Business Terms | Warranty | 12-24 months or 500,000 shots |

| MOQ | 1 set for customized molds | |

| Sample Development | 15-20 days for prototype molds | |

| Export Experience | Exporting to 50+ countries worldwide |

China basket mold manufacturer

fruit basket mold processing

Injection molding of plastic baskets is our commonly used production process, which is relatively quick and cost-effective. Baskets produced using plastic injection molding are extremely durable and have a long service life.

We offer a variety of fruit and vegetable basket molds to meet our customers’ needs. These molds are used to produce fruit storage products in kitchens and refrigerators.

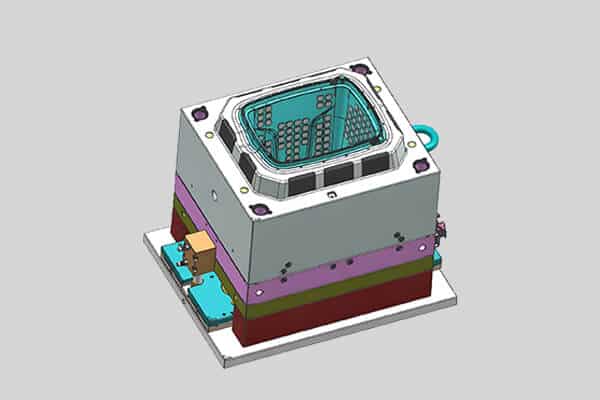

01 product and mold design

YUCO Mold will work with our experienced R&D team to develop and design products and molds based on your requirements. This will help customers develop new products and save costs on new projects.

02 mold flow analysis

YUCO Mold will perform mold flow analysis based on customer requirements to avoid any further problems during mold production.

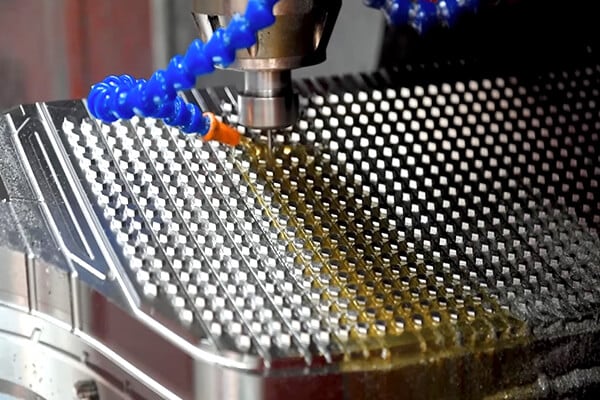

03 mold processing

We pay close attention to detail and process the plastic fruit basket molds, committed to providing customers with high-quality products. YUCO Mold typically provides customers with weekly updates on the progress of plastic mold. If there are any special circumstances, we will contact you immediately.

04 mold assembly

Mold assembly is like assembling a machine. Every part and every screw must be meticulous. Otherwise, the consequences will be severe. This can lead to product defects, hinder production, or even completely damage the mold, resulting in scrap. Therefore, assembly work must be extremely meticulous. During assembly, special attention must be paid to mold cleanliness, especially the water channels and screw holes.

05 photos and videos

YUCO Mold will maintain a one-year record of all mold operation videos. We will send you photos and videos for your inspection or reference of the mold's operation.

06 Packaging and shipping

Delivery time is approximately two weeks. The specific time depends on the complexity and size of the mold. Expedited delivery is also available. YUCO Mold provides customers with complete mold drawings and spare parts before shipment. For standard spare parts, please refer to our list and purchase them in your market.

How to choose a fruit basket mold?

Choosing the right fruit basket mold requires careful consideration of several key factors. These factors will help you make an informed decision and achieve the desired results.

Material

Fruit baskets are made from a variety of materials. Each material has its own advantages, which affect the mold’s durability, flexibility, and ease of demolding.

Plastic is one of the most common materials used to make fruit basket molds. Polypropylene or ABS plastic is typically used in the production of these molds. These plastics offer a good balance between rigidity and impact resistance. They also have a glossy surface, making the fruit basket easy to clean and aesthetically pleasing.

The choice of plastic material must consider the intended use of the fruit basket and the environment in which it will be used. The material used should be suitable for the intended purpose and meet the necessary standards for strength, durability, and safety.

Steel type and quality

For plastic fruit basket molds, the type and quality of steel is crucial. It is the foundation and the starting point of everything. There are many different types of mold steel, such as P20, 1.2344, H13, and S136 hot-rolled tool steel. You may need to consider the following points to select the right steel.

Injection molding requires different plastics for different steel types. Furthermore, there are requirements for corrosion resistance and polishability. Steel with adequate performance is optimal. There’s no need to spend a fortune pursuing higher performance.

Surface treatment is also important. Nitriding can increase the surface hardness of steel and extend its lifespan. Electroplating can modify the properties of mold steel. Some plastics require high brightness and corrosion resistance, so electroplating can be used to improve and modify the steel’s properties.

- Generally, for large production volumes, we strongly recommend using 45# steel for the mold frame and 718H nitriding for the core, cavity, and slider. This mold can produce at least 1 million molds.

- For smaller production volumes, using 45# steel for the mold frame and P20 nitriding for the core, cavity, and slider can produce up to 500,000 molds.

- For production volumes under 200,000, all common steels can be heat treated.

Customized fruit basket mold options

YUCO Mold has an experienced team of engineers who can design and manufacture molds of various shapes and sizes according to customer specifications. Fruit basket molds offer a variety of customization options. These customizations allow users to create unique and practical molds tailored to their needs.

- Size customization: Basket molds allow manufacturers to adjust the diameter, height, and thickness of the mold walls or base. This allows users to create fruit baskets of any size to accommodate small or large quantities of fruit. These baskets can be used for both personal and commercial purposes. These size customizations ensure that the baskets meet specific capacity requirements. These baskets are suitable for storing different types of fruit and various decorative styles.

- Design and shape customization: Fruit basket molds offer a variety of design options. You can choose from a variety of shapes, such as round, oval, and square, as well as more complex designs like woven or geometric patterns. These design features allow users to select a basket that matches their style.

- Texture and finish customization: The texture and finish of a custom mold can greatly affect the look and feel of the final product. Fruit basket molds can optionally add textures such as ripples, lines, or patterns. These textures enhance the basket’s appearance and give it a unique visual appeal. You can choose from matte, glossy, or satin finishes. These options will ensure the fruit stands out and grab your customers’ attention.

- Color customization: The basket mold is available in a variety of colors. This feature allows users to select a hue that matches their brand or personal preferences. Color options range from bold, eye-catching hues to soft pastels, creating a basket with more personality and vitality. YUCO plastic baskets are available in a variety of colors, allowing you to choose a basket that complements your kitchen décor or adds a pop of color to your dining table.

Structural design

The design of a fruit basket mold can have a significant impact on the final product. Design constraints such as wall thickness, part geometry, and undercuts can limit the mold’s design capabilities and restrict the types of fruit baskets that can be produced.

Good structural design not only considers product material properties—such as shrinkage and molding temperature—but also the cooling of the waterway. Excellent structural design can extend the life of the fruit basket injection mold and ensure smooth product production. This is crucial for improving efficiency and reducing costs.

Mold cooling

Those with years of mold experience understand the importance of mold cooling. Due to rising prices and labor costs, the profit potential of shaving a single second off the injection molding cycle is unimaginable when producing high-volume products. However, as production cycles accelerate, mold temperatures rise. If not effectively controlled, this can lead to overheating, prevent molding, or even deformation and failure. Therefore, a well-designed cooling system, including the density, diameter, and interconnection of the water channels, is crucial.

Easy to clean and maintain

Since many fruit basket molds are used frequently, choosing a mold that is easy to clean and maintain is crucial. Mold maintenance primarily involves care and maintenance during the production process. Improper mold maintenance and repair can lead to reduced production quality, increased downtime, and additional repair costs.

Molds require comprehensive maintenance after each use, especially for rust prevention of the molding area and major moving parts. Because molds meet water during production and can be exposed to water during installation or removal, they must be completely dry before applying a protective coating of oil.

Plastic mold manufacturing is highly complex, requiring meticulous attention to detail, from design and processing to assembly, testing, and repair, all the way to commissioning. Many factors can impact mold quality and performance. We need to truly understand it to make molds better.

Budget

When choosing a fruit basket mold, budget is important to consider. Mold prices are influenced by many factors, including material, size, and brand. The upfront cost of manufacturing fruit basket mold can be high. Mold costs depend on factors such as mold size, complexity, and the number of cavities.

We can offer you the best pricing. With a strong network of manufacturers and material suppliers, we select the right suppliers for each product to meet our customers’ expectations at the lowest cost.

How can we ensure consistent quality when using plastic fruit basket molds?

YUCO Mold ensures consistent quality when producing fruit baskets using fruit basket molds by combining process control and quality assurance measures. Here are some strategies manufacturers can employ:

- Regular mold maintenance: Regular maintenance and troubleshooting are essential to ensure that fruit basket injection molds are functioning properly. Molds should be inspected, cleaned, and repaired as needed to ensure consistent quality and prevent defects.

- Equipment calibration: Injection molding machines used in the production process should be calibrated regularly to ensure they are operating within specified specifications. This helps minimize variability and improves consistency during production.

- Process monitoring: Monitoring the injection molding process helps identify and resolve any issues that may arise. This can be achieved by monitoring key process parameters such as temperature, pressure, and cycle time in real time.

- Quality control checks: Quality control checks should be performed regularly throughout the production process to ensure that the final product meets the required specifications. These checks include visual inspections, dimensional measurements, and performance testing.

- Statistical process control: Statistical molding process logs can be used to monitor and control the injection molding process. This helps identify and resolve any issues that may affect the quality of the final product.

Frequently asked questions

How long does it take to make a fruit basket mold?

The manufacturing time for a fruit and vegetable basket mold depends on the complexity of the design and the specific requirements. It typically takes several weeks to complete.

Can you provide references or examples of your previous work?

Yes, we are a reputable mold manufacturer and can provide references or examples of previous work to demonstrate our expertise and quality.

Do you provide technical support after purchasing a fruit basket mold?

Yes, we provide technical support to help you with any questions or concerns you may have after purchasing our product.

Can you handle bulk orders for plastic basket molds?

Yes, YUCO Mold is generally able to handle bulk orders based on our production capacity and resources. It’s best to discuss your needs with us in advance.

Why choose a plastic basket?

Plastic fruit baskets are a practical and affordable option for storing and displaying fruit at home. They are durable, lightweight, and versatile.

One of the main advantages of plastic fruit baskets is their durability. Unlike traditional baskets made from natural materials like wicker or bamboo, plastic baskets are waterproof and moisture-resistant, making them easy to clean and maintain. This means you can wash them regularly without worrying about them getting damaged or losing their shape.

Another advantage of plastic fruit baskets is their lightweight design, making them easy to move and transport. This is especially useful if you frequently rearrange your kitchen or dining room or need to take the basket to a picnic or party. Many plastic fruit baskets come with sturdy handles for easy transport.

Beyond storing fruit, plastic fruit baskets have many other uses. For example, you can use them to hold vegetables, snacks, or even as table decorations. Some baskets even come with removable liners or dividers, making it easy to organize and separate different types of fruit or snacks.

Why choose YUCO molds for fruit basket molds?

YUCO has extensive expertise in plastic basket mold manufacturing and production solutions. We are not just a mold supplier, but a technology provider that optimizes quality, cost, and product performance. Our Projects:

Our Advantages:

- Excellent communication: We are fluent in English, enabling us to effectively communicate with customers on both business and technical matters.

- Quality assurance: We predefine quality requirements before work begins. Qualified quality inspectors conduct on-site quality inspections during production and before shipment. Fruit basket molds produced by YUCO Mold meet global industry safety standards and are resistant to wear and tear under extreme operating conditions.

- Warranty: If any quality issues are found, we will promptly ship replacements.

We will provide you with a competitive quote based on your product and mold requirements. We look forward to working with you to create a better future.

Tel: +86 13586040750