laundry basket mold

YUCO mold is an emerging laundry basket mold manufacturer in China, providing high-quality and competitive laundry basket molds and laundry baskets. Our services include prototyping, processing, trial operation and mass production.

Plastic laundry basket molds from China manufacturer

Plastic laundry basket molds are a key component in producing durable and functional laundry baskets. These molds are designed to produce plastic baskets that are not only efficiently designed but also meet the different needs of consumers and businesses.

- We have a large number of 3-axis and 5-axis machining centers to manufacture complex molds, supplemented by professional CAD/CAM/CAE design.

- We produce the best quality molds with an average life of 300,000 times. Each basket will have the same high-end quality.

- The laundry basket molds designed by our company are known for their durability, ensuring long life and resistance to bending or breaking. The injection molding process is efficient and can be mass-produced.

- We can customize laundry basket molds for customers according to customer requirements, and manufacturers can easily modify the design, size and color to cater to market trends and consumer preferences.

laundry basket mold specifications

| Specification Category | Parameter | Typical Value/Range | Remarks |

|---|---|---|---|

| Mold Material | Core & Cavity Steel | Pre-hardened: P20 (1.2311), P20+Ni Hardened: H13 (1.2344), NAK80 Stainless: ASSAB Stavax | Selection based on budget and production requirements |

| Mold Base Steel | S50C, P20 | Selection based on budget and requirements | |

| Core & Cavity Hardness | Pre-hardened: HRC 30 32±1 Hardened/Heat Treated: HRC 50 52±1 | Influences mold life and stability | |

| Basic Dimensions | Mold Dimensions | 650×550×500mm (Example) | Adjustable based on product specifications |

| Product Dimensions | 400×300×350mm (Example) | Typical household laundry basket size | |

| Capacity | 30-60L | Designed according to market demands | |

| Mold Structure | Number of Cavities | 1-2 | Determined by production needs |

| Parting Line | Horizontal | Ensures smooth product ejection | |

| Runner System | 1. Cold runner 2. Hot runner 3. Cold+Hot runner | Chosen based on product requirements and production efficiency | |

| Core Pulling / Ejection System | Motor, oil cylinder, stripper plate, angle pin, ejector pin, etc. | Dependent on product design | |

| Technical Parameters | Mold Weight | 1000-2000kg | Varies with mold size |

| Injection Pressure | 80-120MPa | Dependent on product design | |

| Mold Temperature | 40-80℃ | Adjusted according to material properties | |

| Cooling Time | 25-45s | Impacts production efficiency | |

| Design Features | Cooling System | Core: Baffle or bypass cooling Cavity Plate: Chain drilling type cooling | Ensures rapid and uniform cooling |

| Mold Accessories | Compatible with DME/HASCO standards | Guarantees accessory quality and interchangeability | |

| Venting System | 0.02-0.03mm deep vents | Prevents short shots and surface defects | |

| Basket Weave Structure | Round/Square/Diamond holes | Balanced design for ventilation and strength | |

| Surface Finish | Surface Treatment | Texturing, EDM, Polishing | Determined by product requirements |

| Surface Roughness | Ra0.4-0.8μm | Ensures a smooth product surface | |

| Dimensional Tolerance | ±0.1mm | Guarantees product precision | |

| Mold Life | Pre-hardened Steel | 200,000~300,000 shots | Under ideal operating conditions |

| Hardened/Heat Treated Steel | 600,000~800,000 shots | Under ideal operating conditions | |

| Stainless Steel | 1,000,000 shots | Under ideal operating conditions | |

| Application Parameters | Applicable Injection Molding Machine | 280-500 tons | Determined by product size |

| Product Material | PP/PE/ABS | Common durable plastic materials | |

| Cycle Time | 45-90s | Includes injection, cooling, mold opening, and ejection | |

| Delivery & Service | Delivery Time | 80~90 days | T1 samples provided |

| Packaging | Standard wooden case | Ensures safe transportation | |

| Production Service | Pilot run and molding production available | Offers complete production solutions | |

| Special Features | Anti-Deformation Design | Reinforcing rib structure | Enhances product rigidity |

| Handle Design | Ergonomic | Facilitates handling and use | |

| Stacking Design | Stackable, space-saving | Convenient for storage and transport |

China basket mold manufacturer

laundry basket mold processing

Laundry baskets are made with plastic injection molds called laundry basket plastics molds. Most molds consist of two halves, which are joined when the plastic is heated, resulting in an appearance of one piece.

After the plastic has cooled in the mold, the basket can be removed. Different types of laundry baskets can be accommodated by different plastic molds. There are commonly found features on laundry basket plastic molds like handles and vents. Featuring handles for easy carrying, as well as vents to prevent moisture build-up, the laundry basket can be easily moved.

01 customization

Our experienced R&D team will develop and design laundry basket and mold according to your requirements. This will help customers who are developing new products and save costs for new projects.

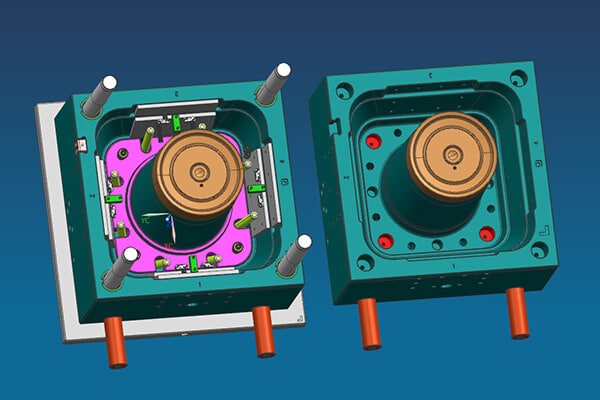

02 mold design

YUCO's highly skilled engineers utilise advanced CAD, CAM and CAE software to provide customers with practical design solutions.

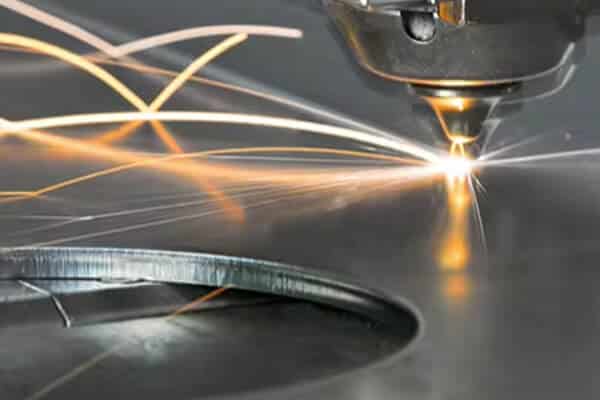

03 mold manufacturing

Choosing good materials must ensure quality and durability. YUCO MOLD owns high-speed EDM, EDM mirror spark machine, CNC machining center and other excellent equipment to ensure the production of high quality molds.

04 mold inspection

YUCO MOLD adopts strict inspection procedures, including First Article Inspection (FAI) and Coordinate Measuring Machine (CMM) inspection with full size inspection report.

05 mold testing

We will carry out high pressure injection test and long time injection test on the molds. We will send you photos and videos for inspection or reference of mold running.

06 Packaging and shipping

YUCO MOLD provides comprehensive shipping lists and packaging reports to ensure your molds are delivered safely and efficiently, ready for production.

Why choose YUCO laundry basket mold

Plastic basket molds are one of the most popular injection molds in the plastic processing industry. They are used in a wide range of applications in daily life, from small baskets suitable for storing

Tight tolerances

Pricing

Customization

Quality control

8/24x7 Service

10,000+ Capacity

Frequently asked questions

Composition of laundry basket mold

- Core: the main body of the mold, which plays the role of fixing the cavity.

- Cavity block: where the plastic product is molded.

- Slider: It plays the role of demoulding guide when the core moves, and it is also one of the important parts to ensure the dimensional accuracy of plastic products.

- Demolding plate: It plays a decorative role and has a certain guiding role. These four main parts cooperate with each other during the molding process to finally form a plastic product that meets the requirements.

How to make the plastic basket?

A laundry basket mold is a plastic injection mold used to make laundry baskets. These laundry baskets are made using plastic molding technology.

- #1 Injection molding: First, we need to put the material into the injection molding machine, heat and melt the plastic particles in the hopper, and press the melted plastic particles from the injection molding machine into the mold. At the same time, it is necessary to ensure that the pressure and temperature control during injection molding are appropriate.

- #2 Cooling: After injection molding, it needs to be cooled. This process requires the hot plastic in the mold to cool before taking it out. During the mold removal process, try to avoid impacting the product to avoid defects.

- #3 Trimming: After the mold is taken out, the product needs to be trimmed, including removing unnecessary parts such as flash and burrs, as well as surface grinding and polishing. This step is to make the product surface smoother and more beautiful.

- #4 Packaging: Finally, we need to package the product to ensure that the product will not be damaged during transportation. The packaging needs to be selected according to the size and weight of the product.

How do cold runners and hot runners differ?

- Cold runners are most suitable for recycling plastic material, and could save hot runners investment.

- In hot runner baskets, runner waste is not present, while in cold runner baskets, runner waste is present. This saves plastic.

- There is a slight difference in cycle time between cold runner baskets and hot runner baskets when producing the same basket.

- Due to higher injection pressures in cold runner moulds, hot runner moulds do not have flashes besides the injection gate, but cold runner moulds do.

- Cold runner moulds have a shorter lifetime because of high injection pressure.

Why choose YUCO molds for laundry basket molds?

With our capabilities and expertise, it is the goal of YUCO mold to efficiently perform personalized customization and one-stop laundry basket mold solutions to meet customer needs. To this end, YUCO mold has designed a variety of different basket molds.

Although their prices depend on the size of the basket mold and the custom design. However, the molds we produce ensure affordability, high quality, and excellent precision. Our average delivery time is about one week. However, if the customer needs the mold urgently, we also provide expedited delivery services. We take every precaution to meet the needs of customers for the products they need. Tell us your requirements for products and molds, as well as detailed information about the supporting injection molding machine, which will help us provide you with a quotation as soon as possible.

Looking forward to in-depth and long-term cooperation with you.

Tel: +86 13586040750