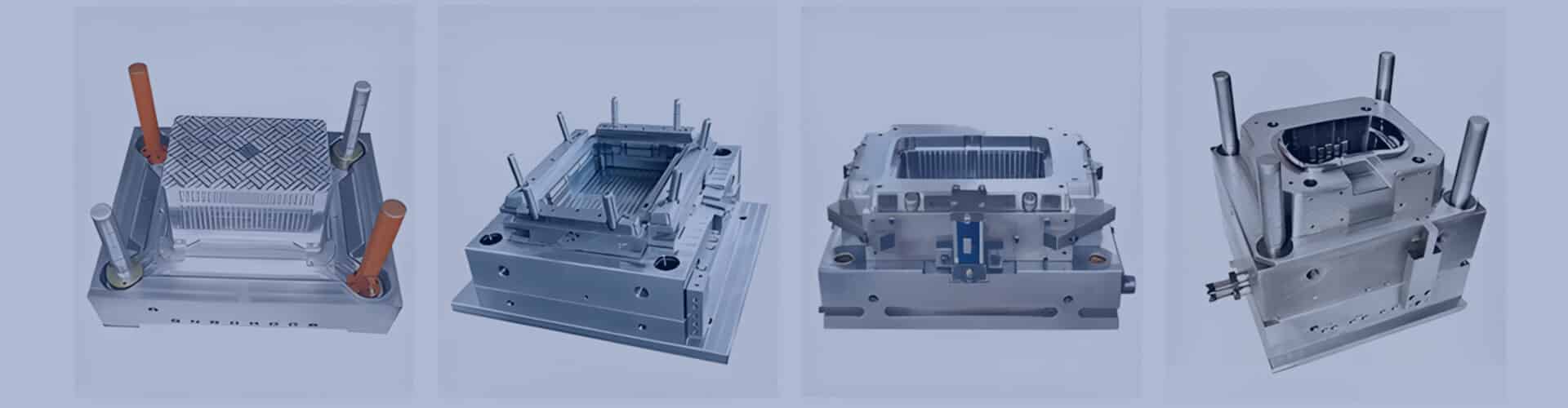

rattan basket mold

Backed by experienced engineers, YUCO Mold provides customers with a one-stop solution, from rattan basket design and mold design to production and delivery.

Plastic rattan basket molds from China manufacturer

- YUCO Mold offers plastic wicker basket molds in various sizes. We can customize the size based on your requirements and design. We can also custom-make molds based on your samples.

- YUCO uses hot runner system technology to improve the quality of plastic woven baskets, reduce production costs, and save time.

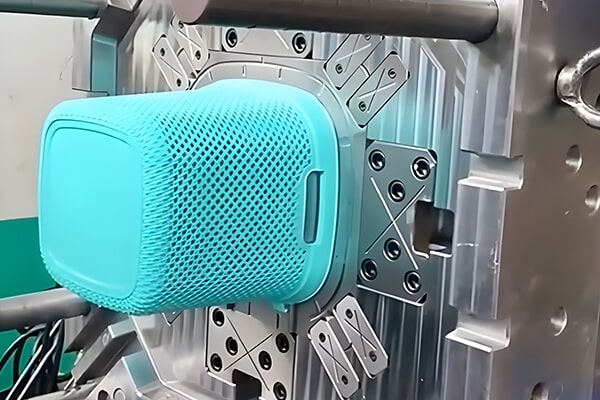

- Compared to natural rattan, imitation rattan baskets (primarily made of PP/PE) offer a smooth, even surface, high strength, excellent flexibility, and durability. They are also waterproof, sun-resistant, mildew-resistant, moth-resistant, hygienic, and easy to clean.

rattan basket mold specifications

| Specification | Details |

|---|---|

| Material | High-grade aluminum alloy (6061/6063-T6 series) with optional stainless steel (304/316 grade) for extended durability |

| Mould Tolerance | ±0.05mm precision machining |

| Surface Treatment | Polished, anodized, or nickel-plated options available |

| Cavity Count | Single to 8-cavity configurations available |

| Mould Size Range | Small: 10-30cm Medium: 30-60cm Large: 60-100cm Custom sizes available upon request |

| Design Capabilities | 3D modeling with CAD/CAM integration Customizable patterns and textures Traditional Chinese weaving patterns available |

| Production Capacity | 100-150 sets monthly |

| Mould Lifespan | 100,000+ production cycles under standard conditions |

| Lead Time | Sample: 7-15 days Mass production: 25-40 days |

| Quality Control | ISO 9001:2015 certified processes 100% inspection before delivery Material composition verification |

| Technical Support | Free mould design consultation On-site technical assistance available Mould maintenance training |

| Application Areas | Household storage baskets Decorative display items Gift baskets Specialized industrial containers |

| Customization Options | Logo embossing Custom weave patterns Handle variations Special edge treatments |

| Heating System | Hot runner system with zoned temperature control (120°C-220°C) |

| Cooling System | Water cooling channels with optimized layout for uniform temperature distribution |

| Warranty | 1-year standard warranty against manufacturing defects |

China basket mold manufacturer

Plastic rattan basket production process

Plastic rattan basket molds are used to make plastic rattan baskets. The male and female molds are typically separate pieces that come together to create the shape of the basket. The inner surface of the mold features a rattan basket weave pattern.

This mold has a specific shape and design and is used for mass production of rattan baskets. Injection molded rattan baskets are commonly found in stores and are more affordable than baskets made with other mold types.

Determining the materials and molds

First, we need to determine the materials and molds based on the desired specifications, dimensions, and shape of the plastic rattan basket. Choosing the right materials and molds will ensure quality and durability.

Preheating

The mold requires preheating during the production process to ensure the appropriate and uniform temperature during injection molding. The preheating temperature needs to be adjusted based on the material type and manufacturer's requirements.

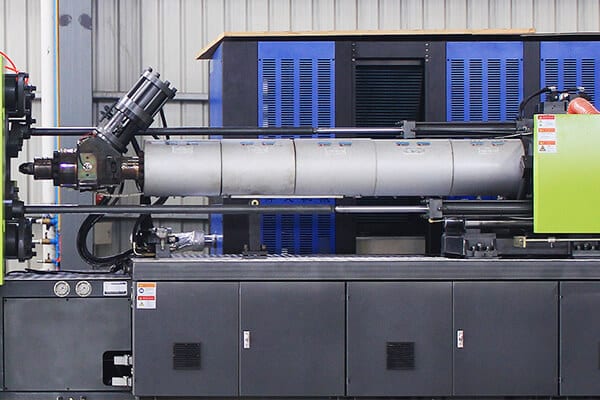

Injection molding

After preheating, the material is placed in the injection molding machine for injection molding. First, the plastic pellets in the hopper are heated and melted, and then the molten plastic pellets are pressed from the injection molding machine into the mold. The pressure and temperature must be properly controlled during the injection molding process.

Cooling

After injection molding, cooling is required. This process allows the hot plastic in the mold to cool before removal. During the mold removal process, minimize impact on the product to prevent defects.

Trimming

After the mold is removed, the product needs to be trimmed. This includes removing unnecessary parts such as flash and burrs, and polishing the surface to achieve a smooth and aesthetically pleasing finish.

Packaging and shipping

Finally, we need to package the product to ensure it is not damaged during transportation. The packaging should be selected based on the size and weight of the product.

How to choose a plastic rattan basket mold?

When choosing a plastic rattan basket mold, you need to consider several factors to ensure the right choice. These factors include:

purpose and function

Define the purpose and function of the rattan basket. Consider the type of items the basket will hold, such as groceries, toys, or gifts, as well as the environment in which it will be used (e.g., home, outdoor, commercial). This will help determine the size, shape, and design of the mold required. For example, a basket for shopping may require a sturdy handle, while a basket for storing items may require a larger capacity.

Mold material

The material’s properties directly impact the mold’s durability and lifespan. Specifically, mechanical properties such as hardness, strength, toughness, wear resistance, and corrosion resistance significantly impact the mold’s lifespan. For example, alloy tool steel and stainless steel offer high strength, toughness, and excellent wear resistance, making them suitable for manufacturing large, complex, and high-precision plastic molds. Choose a rattan basket mold made of durable materials, such as steel or high-quality plastic. These materials can withstand repeated use, ensuring the mold’s longevity.

We use imported DIN 1.2738 steel to ensure mold durability. Additionally, check if the mold has features such as reinforced edges or thickened walls for enhanced durability.

Manufacturing process

The mold’s manufacturing process directly impacts its precision and surface quality, and thus its lifespan. YUCO utilizes advanced manufacturing processes and technologies to improve mold precision and surface quality, while also reducing wear and corrosion during use. With the help of our experienced engineers, we can maintain tolerances within +/- 0.002 mm for rattan basket molds.

Ease of use and release

Look for a plastic rattan basket mold that is easy to use and has excellent demolding properties. Plastic rattan storage basket molds with a well-designed structure, reliable operation, and an easily controlled molding process guarantee the quality of your rattan storage baskets. Consider molds that are easy to assemble and disassemble, as well as easy to remove the finished baskets. Good demolding properties reduce the risk of basket damage and improve production efficiency.

Production efficiency

Consider the mold’s production efficiency. Choose molds that are quick to assemble and disassemble, as well as easy to clean and maintain. Furthermore, consider using multiple molds to increase production efficiency. It is also important that the mold does not generate excessive scrap during production.

Cost and budget

The cost of using molds to produce plastic rattan baskets should be reasonable. This includes the cost of the mold itself as well as the materials and labor required to produce the baskets. Designers also strive to make molds durable enough for repeated use, spreading the cost over multiple production runs. When making your decision, it’s important to balance cost and quality and choose a mold that offers the best value.

Manufacturer and supplier reputation

Choose molds from reputable manufacturers and suppliers. Ensure they offer good after-sales service and technical support. Also, check whether they offer a product warranty and timely maintenance and repair services, as these are crucial to ensuring the quality and longevity of the mold.

Mold design must be easy to use and maintain

Molds should be user-friendly. This means they should be easy to assemble, disassemble, and clean. Overly complex molds can lead to errors during production, resulting in defective baskets. Proper maintenance and replacement of specialized or consumable parts within the mold can help extend the mold’s lifespan.

Mold lifespan

The average lifespan of a rattan basket mold depends on the material it’s made of. Generally, plastic molds can last up to five years with proper care and maintenance. Reasonable production planning, control of the mold’s operating environment, and reduction of the impact of temperature, pressure, corrosion and other factors on the mold can extend the mold’s service life.

Plastic rattan basket mold applications

Imitation rattan baskets are made of PP plastic and mimic natural rattan. They offer flexibility, stylish designs, easy cleaning, and are moisture- and insect-resistant. They are affordable and retain the charm of traditional rattan art while meeting modern needs. These products combine traditional craftsmanship with the advantages of modern materials to meet a variety of needs:

- Recycling: Durable sorting baskets

- Retail packaging: Lightweight and attractive product display baskets

- Food service: Easy-to-clean and disinfect food storage baskets

- Landscaping: Outdoor tool and plant transport baskets

- Home storage: Airy and transparent household storage baskets

Why choose YUCO molds for rattan basket molds?

YUCO Mold has an annual production capacity of 900-1000 molds. Since its establishment, we have been committed to providing high-quality, durable plastic basket molds.

To ensure each mold meets exacting standards, the YUCO mold team utilizes only high-quality materials and advanced technology. Our ISO-certified manufacturing facility and stringent quality control systems ensure that each mold is manufactured with precision and attention to detail. With these highly reliable and trustworthy methods, you can be assured that your custom rattan basket mold will be durable and of exceptional quality.

YUCO aims to make our molds as cost-effective as possible. If you're interested, please feel free to contact us.

Tel: +86 13586040750