storage basket mold

YUCO manufactures China's most innovative storage basket molds and is a renowned manufacturer of plastic storage basket molds. We can also customize the entire design of storage container molds based on detailed customer specifications.

Plastic storage basket molds from China manufacturer

- YUCO has a professional production design team that saves time while simultaneously processing molds, shortening mold production cycles.

- We continuously improve and refine our molds and services, and the technical support we provide to our customers is exceptional and high-quality.

- With over a decade of expertise, we specialize in manufacturing precision plastic injection molds. We equip our factory with a complete CAD/CAM/CAE system.

- Experience comprehensive, one-stop service for plastic storage baskets and molds, ensuring efficiency and cost savings.

storage basket mold specifications

Whether on supermarket shelves or in your home’s storage space, plastic storage baskets are ubiquitous because they’re lightweight, durable, and stackable, reliably holding large items.

| Specification | Details |

|---|---|

| Mold Material | – Core & Cavity: P20, 2738, S136, H13, or other high-quality tool steel – Mold Base: LKM, HASCO, or custom mold base material depending on requirements |

| Mold Type | – Injection Mold: Typically a 2-plate or 3-plate mold for efficiency. – Stack Mold: Optional, for high-volume production |

| Mold Design | – Structure: Open cavity, multi-cavity mold for large batches – Core & Cavity: Internal part cooling channels to optimize heat distribution |

| Product Size | – Dimensions of Basket: Custom sizes based on client’s requirements, typically ranging from 20cm to 60cm in length, 10cm to 30cm in height and width |

| Material Type | – Common Materials: PP (Polypropylene), HDPE (High-Density Polyethylene), PVC, ABS, PS – Color: Custom color matching (using masterbatch or pigments) |

| Mold Surface Finish | – Finish Types: Mirror, texture, matte finish – Texturing: Can be textured with fine-grain texture, sandblasted or polished for aesthetic or anti-slip surfaces |

| Injection Pressure | – Pressure Range: Typically 800-1500 bar depending on material and mold complexity |

| Injection Speed | – Speed: Fast injection for thin-walled designs (e.g., storage baskets), typically around 30-100 cm/s depending on product complexity |

| Cycle Time | – Typical Cycle Time: 30-60 seconds for small to medium size baskets – Dependent on material, product thickness, and mold cooling |

| Ejection System | – Type: Pneumatic or hydraulic ejector pins – Ejector Plate: For automatic removal of molded baskets from the mold cavity |

| Cooling System | – Cooling Channels: Optimized cooling layout using conformal cooling channels for efficient cycle time reduction – Typically water-cooled channels |

| Gate Type | – Gate Design: Pinpoint gate, edge gate, or hot runner system depending on mold design and material used |

| Mold Life | – Expected Mold Life: 500,000 to 1,000,000 cycles depending on material, mold steel, and maintenance |

| Tolerance | – Typical Tolerances: ±0.1mm to ±0.5mm depending on the product’s application and material characteristics |

| Mold Temperature Range | – Working Temperature: 30°C to 70°C (depending on material) |

| Injection Unit | – Injection Capacity: Customized based on the size of the mold (typically 200-800 tons clamping force) |

| Mold Closing Force | – Closing Force: 500 to 1000 tons (depending on the size of the mold and material used) |

| Mold Setup Time | – Setup Time: 1-2 hours for mold setup, cleaning, and testing for small to medium-sized production runs |

| Production Capacity | – Output: 1000-2000 pieces per day (depending on basket design and complexity) |

| Tolerances for Injection Molded Basket | – Dimensional Tolerance: ±0.1mm to ±0.5mm – Weight Tolerance: ±5% to ±10% (depends on basket size and material density) |

| Quality Control Standards | – QC Tests: Dimensional inspection, material testing, weight measurement, color matching tests, and visual inspection for defects |

| Post-Processing | – Secondary Processes: Labeling, embossing, screen printing, assembly of handles or additional parts |

China basket mold manufacturer

Plastic storage basket production process

The storage basket mold consists of two plates: the core and the cavity. The mold has a cycle time of 10.8 seconds, including injection and cooling time. The number of cavities in a storage basket mold can range from one to four. To manufacture the mold, we use P-20-2738 pre-hardened HRC40-42 material, which we carefully polish, chrome-plated, nitrided, and vacuum-hardened.

quote information requirements

YUCO requires the following details to ensure we provide you with an accurate and competitive quote:

- Submit your product drawings or sample photos with dimensions. We will quote and process based on the 3D file or sample.

- Please include your logo for custom options.

- Specify the order quantity.

- Shipping destination.

Payment

Finalize and confirm the exact price, delivery time, drawings, payment terms, and other important details. The YUCO sales team will issue a pro forma invoice, stamped with the official YUCO company seal for verification. The customer pays a deposit and provides a bank receipt for confirmation. We accept payment methods such as T/T, PayPal, or D/P.

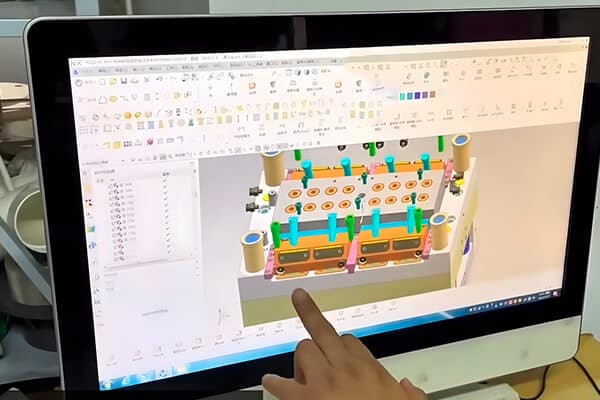

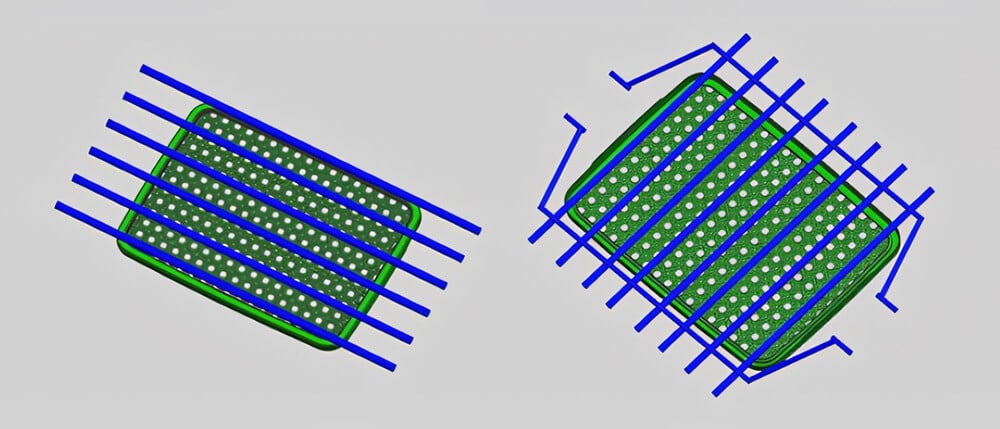

Mold Design

Our designers are proficient in plastic storage basket mold design. We use mainstream software such as Solidworks 2010, Pro-Engineer, Unigraphics, and AutoCAD 2010 (2D: .dwg .dxf .pdf, 3D: .igs .step .x_t .prt .sldprt .easm) to complete detailed product and mold design based on your needs.

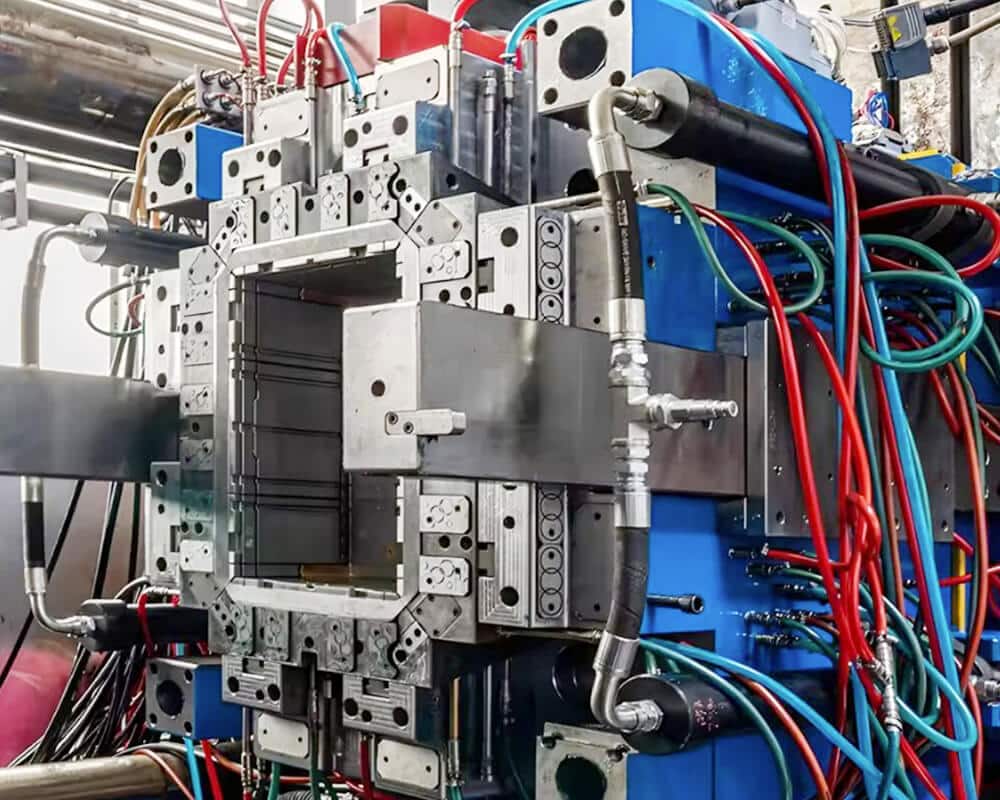

Processing Equipment

YUCO Mold utilizes advanced mold equipment to ensure mold quality and precision. We utilize CNC milling machines, presses, engraving machines, EDM machines, grinders, drill presses, and other high-precision mold equipment to ensure superior mold quality. We not only provide technical support but also offer complete solutions for the plastic injection molding industry.

packaging and delivery

Once the customer settles the final payment, YUCO will arrange shipment. For complex molds, we typically wait for approximately 45-60 days. Your order is considered complete once you receive and are satisfied with the goods.

Plastic storage basket mold technical documentation

The core of efficient, large-scale, and continuous production of storage baskets lies in a precision industrial piece of equipment: the plastic storage basket mold. From plastic pellets to the final basket shape, everything depends entirely on a highly complex, meticulously designed and engineered injection molding system.

Plastic storage basket design

The design of plastic storage basket molds presents several challenges, primarily stemming from the product’s functional and geometric requirements. Key design considerations include:

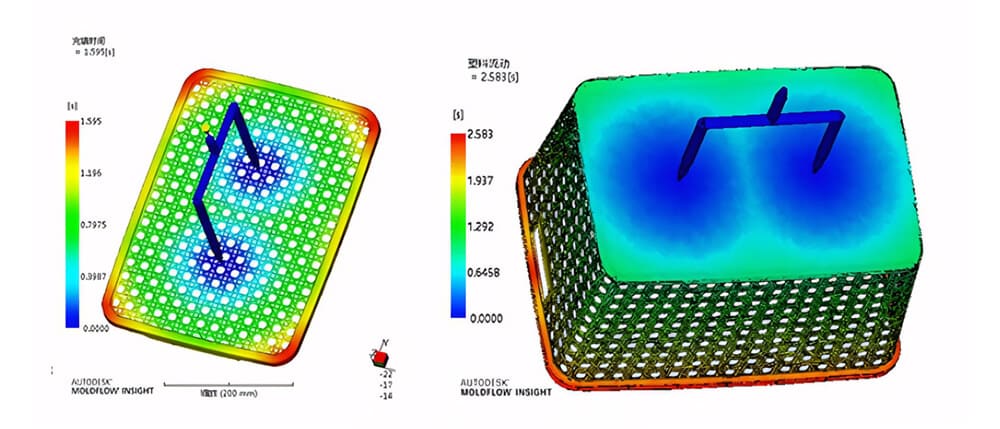

Uniform wall thickness and cooling control

Storage baskets require sufficient strength and load-bearing capacity, so uniform wall thickness distribution is crucial. Uneven wall thickness can lead to uneven cooling, potentially causing warping, deformation, or stress cracking. Cooling system design is crucial to ensure effective heat dissipation to avoid localized overheating or undercooling that can slow production and negatively impact basket quality.

Deep cavity walls and flow resistance

Storage baskets typically have deep walls, which require molten plastic to flow a long distance to fully fill the cavity. Flow resistance increases with distance, and poor flow channel design can lead to incomplete filling (short shots), flow marks, or weld lines. This not only affects molding quality but can also result in strength and cosmetic defects in the final product.

Bottom support structure and cooling efficiency

To support the weight and prevent sagging, the bottom of a storage basket often features a mesh or rib structure. These areas can become “hot spots” where heat accumulates, resulting in slower cooling. Mold cooling channel design requires special attention to ensure uniform and effective cooling in these areas to prevent hot spots and uneven cooling that can lead to deformation or stress accumulation.

Surface texture and mold release requirements

Storage baskets often feature a non-slip texture on their bottoms to increase friction and durability. However, the texture depth and draft angle must be carefully designed to prevent sticking. Complex textures require a smooth mold surface finish, which is crucial for both product appearance and mold release.

Stacking/nesting design compatibility

Storage baskets often require stacking or nesting capabilities to optimize storage and shipping space. Therefore, mold design must ensure product shape accuracy during mass production and ensure stable stacking or nesting of baskets molded from multiple molds.

Plastic storage basket mold system

To overcome the challenges and ensure efficient production, plastic storage basket molds utilize several precisely engineered systems:

Slide motion system (Side action)

Side handles, reinforcements, or bottom edges of storage baskets often create undercuts, making them impractical to eject via standard core/cavity separation. The solution is the use of slide components, typically driven by hydraulic cylinders or tilting guide pins. These slides follow a precisely calculated path before and during mold opening to prevent undercuts on the plastic part. The slide’s motion accuracy and durability (achieved through high hardness and effective lubrication) directly impact mold life and product quality.

Ejection system

Once the mold cools and solidifies, the molded basket must be cleanly ejected from the cavity. To prevent deformation, the mold utilizes a combination of ejector pins and ejector vanes. The ejector vanes provide uniform support over a large area, while the ejector pins are used for localized, critical features. The entire ejection system is driven by the injection molding machine’s ejector mechanism and ensures accuracy through precise motion path and force control.

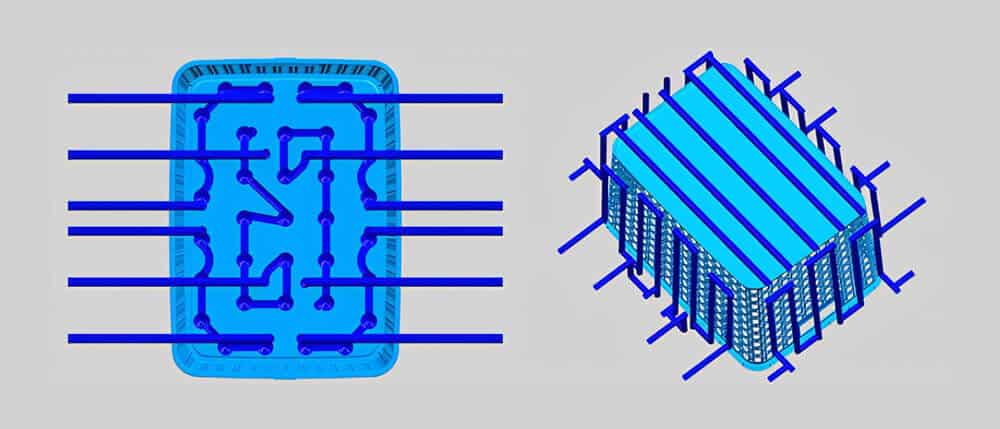

Efficient cooling system

To shorten production cycle times and eliminate hot spots, molds utilize a dense network of cooling channels. Cooling channels should be designed as close to the cavity and core surfaces as possible, especially in hot spots such as deep cavities, grid nodes, and rib intersections. Channel diameter, connection method, and coolant flow control have a direct impact on cooling efficiency. Deep-cavity molds often require specially designed baffle cooling channels to ensure uniform cooling and effectively reduce production cycle times.

Runners and gating systems

The mold’s runners and gating system are critical to the smooth flow of molten plastic. Precise runner design ensures uniform flow of molten plastic into the cavity, avoiding areas of overfill or underfill. Using a hot runner system can reduce cooling time and minimize material waste. For large storage baskets, molds often utilize multiple hot runner gates to ensure even filling and improve production efficiency.

Hot runners

The temperature control accuracy of a hot runner system directly impacts product quality. Uneven temperatures can lead to poor molten plastic flow, impairing filling efficiency and even causing weld lines or surface defects. Therefore, choosing a hot runner system with multi-zone independent temperature control can maintain uniform temperature distribution during production and avoid quality issues caused by temperature fluctuations.

In multi-cavity molds, plastic flow must be balanced, and all gates should open simultaneously to ensure uniform plastic filling of each cavity. Unbalanced runner design can result in underfilling in some areas and overfilling in others, compromising final product quality. Runner dimensions require careful design. Too small will result in pressure loss, while too large will prolong the plastic’s residence time in the system, compromising material properties.

Material selection

The durability of a plastic storage basket mold directly determines its lifespan, maintenance costs, and production stability:

The cavity and core molds must be made of mold steels with high hardness and good thermal conductivity, such as P20 and H13, to ensure stable performance under high temperature and high pressure conditions. These steels are not only wear-resistant but also have excellent polishability and toughness, ensuring mold precision over long-term use.

Guide pins and bushings are typically made of hardened high-carbon alloy steel; ejector pins and return rods are typically made of tool steel or specialized ejector pin materials; and the mold plates are constructed of high-strength structural steel to ensure overall mold stability and durability.

Common mold steels include P20 (core and cavity) and C45 (mold base), typically with a hardness of 35-38 HRC. With proper heat treatment, these steels can effectively extend mold life and reduce maintenance requirements during production.

Plastic storage basket mold manufacturing

High-quality plastic storage basket molds rely on precision machining and strict quality control:

Core manufacturing technologies

- CNC machining centers: Used for rough and finish machining of molds, ensuring high positioning accuracy and repeatability.

- Electrical discharge machining (EDM): Suitable for deep cavities, complex contours, and high-precision cutting, ensuring precision in details and difficult-to-machine areas.

- Precision grinding: Used to ensure part flatness, dimensional tolerances, and precise fit, especially on the guide pin/bushing interface and sliding surfaces of the mold.

Surface treatment

- Polishing: Gradually removes machining marks to achieve a mirror finish, ensuring a smooth part for easy demolding.

- Surface enhancement: Technologies such as nitriding or PVD coating improve component hardness, wear resistance, and corrosion resistance, extending the life of the mold.

Commissioning and production

After mold manufacturing is complete, it undergoes rigorous commissioning and trial production to ensure production capacity and product quality:

Dry cycle

Mold opening and closing, slide movement, and ejector function are inspected to ensure there is no sticking or abnormal noise.

Sampling (Test shot)

Production material is used for trial production to check the filling integrity, dimensions, appearance, and quality of the product. Based on the sample results, the injection process (such as temperature, pressure, and speed) is adjusted to optimize production efficiency and quality.

Mass production

After passing verification, the mold enters the mass production stage, where it begins to withstand frequent mechanical cycles, temperature fluctuations, and material wear over a long period of time. Stability and high yield rates during the production process guarantee the quality of the final product.

YUCO Mold maintains a dedicated quality control department to ensure that every component we manufacture is within specified tolerances and exceeds our customers’ stringent standards. All our measuring and inspection equipment is regularly calibrated to ensure accuracy and consistency.

Storage basket mold project management

Communication is key. Good project management is crucial to success, customer satisfaction, and the overall experience of working with YUCO. We expect molds to function perfectly at every stage, including injection molding. Therefore, all processes are strictly controlled to ensure molds are delivered on time and function perfectly upon delivery.

As a customer, you can expect all project tracking and documentation, such as progress reports, to be submitted on time and accurately reflect our current progress. Maintaining consistent communication and responding to any customer questions is just another level of support guaranteed by YUCO.

Why choose YUCO molds for storage basket molds?

YUCO Mold specializes in producing a wide variety of plastic basket molds, boasting advanced design capabilities and high-precision production. With over 1,000 mold designs and extensive design experience, we offer a wide range of plastic storage basket injection molds to meet your requirements and expectations.

YUCO has a large customer base across the country. Our customers are all over the world, such as the United States, the United Kingdom, Canada, Sweden, Italy, Russia, India, Iran, etc. We always accept small orders to support customers to better carry out marketing.

Working with YUCO, we offer a wide range of storage basket solutions. Through our comprehensive services in industrial design, prototyping, and plastic mold design, your company will have the opportunity to achieve maximum performance in a shorter timeframe, produce parts or molds in the most economical manner, and optimize all production processes.

Tel: +86 13586040750