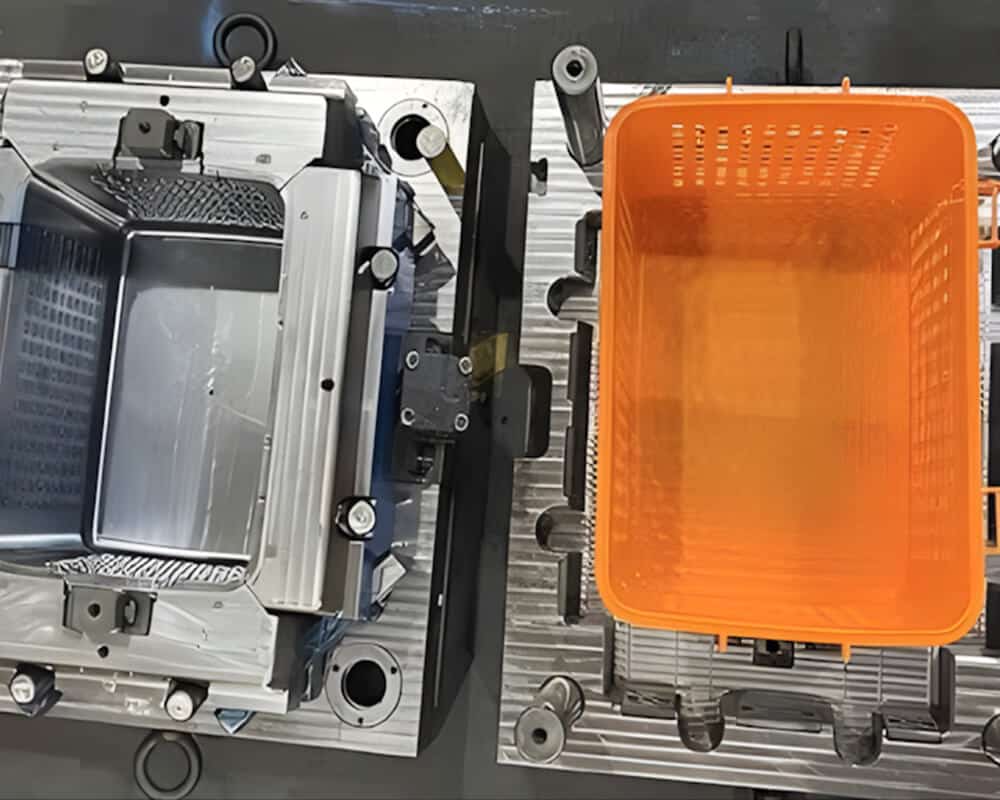

supermarket shopping basket mold

YUCO MOLD is a leading supplier and exporter of supermarket shopping basket molds. We offer a one-stop shopping basket solution, including product design, mold design, mold manufacturing, plastic part fabrication, and secondary processing services.

Plastic supermarket shopping basket molds from China manufacturer

- We have extensive experience in supermarket shopping basket mould manufacturing and an excellent product development team, capable of providing all the details of a 3D mould design within a day. We can complete mould manufacturing within 45 days.

- We use advanced components from world-renowned brands. To manufacture precision shopping basket moulds, we use a full range of advanced equipment, including CNC machining centres, large gantry milling machines, vertical milling machines, CNC engraving machines, EDM machines, and wire-cutting machines, ensuring high-precision, large, and complex moulds.

- We work closely with our customers and provide timely communication to ensure they receive high-quality, fast-production moulds. We offer free support, including maintenance services, product analysis, videos, and consultations. Customers can also communicate with our technicians online for business strategies and answers to their inquiries.

supermarket shopping basket mold specifications

| Specification | Details |

|---|---|

| Material | High-Quality Steel (P20, H13, S136, or Custom) |

| Mold weight | 500 kg – 1500 kg (depending on basket design and size) |

| Mold structure | Two-Plate or Three-Plate Mold |

| Injection system | Hot Runner or Cold Runner System |

| Cavity type | Single or Multi-Cavity (up to 16 cavities depending on basket size) |

| Cycle time | 25-45 seconds per cycle |

| Mold life | 500,000 to 1,000,000 shots |

| Finish | High-Polish or Textured Finish (optional: anti-scratch, anti-slip) |

| Basket dimensions | Customizable, typically 400mm x 300mm x 250mm or tailored per customer’s requirement |

| Mold tolerance | ±0.05mm (custom tolerances available based on customer needs) |

| Ejection system | Pneumatic or Mechanical Ejection |

| Cooling system | Precision Cooling Channels for Fast and Efficient Cooling (reduce cycle time) |

| Production rate | Up to 2000 units/day (depending on mold configuration and material) |

| Mold base | Standard Mold Base or Customizable |

| Injection pressure | 800-1200 bar |

| Mold temperature | 30°C – 80°C (depending on plastic material) |

| Plastic material | HDPE, PP, or Custom (depending on client preference) |

| Application | Designed for manufacturing supermarket shopping baskets, can be adapted for other similar products |

| Service life | High durability with low maintenance, ideal for mass production |

China basket mold manufacturer

Plastic supermarket shopping basket production process

Injection molding is an efficient and economical method for mass-producing supermarket shopping baskets. To achieve scaled production and standardized product appearance, we have a complete production line, ensuring consistent product quality.

Our factory operates in a highly automated, intelligent, and pollution-free environment. A single operator controls and manages all relevant machines. Plastic shopping basket molds can be produced on standard injection molding machines.

Key features of supermarket shopping basket molds

Moldflow features

YUCO Mold performs Moldflow analysis on all molds we produce. Moldflow offers the following advantages:

- Flowability analysis: This analysis determines whether the component can be filled. This analysis provides information such as injection pressure and mold pressure.

- Filling problem analysis: This analyzes the part for filling problems such as short shots, bubbles, and uneven filling. These problems can be addressed by adjusting process conditions such as gate location and injection rate.

- Deformation prediction: This predicts part deformation and compares the effects of gate location, wall thickness changes, or design changes on deformation.

- Mold prototype inspection: Use “short shots” to detect mold prototype issues, and mold flow analysis reveals which improvements are effective and cost-effective.

- Cooling system efficiency check: Improve the efficiency of the cooling circuit through cooling analysis and optimize it before mold opening.

- Weld line problem repair: Predict weld line locations and optimize weld quality to ensure better mold results.

Mold cooling system design

Cooling system design is a relatively complex task, requiring consideration of multiple factors to determine the specific location and size of the cooling system.

- Critical components, such as the moving mold or insert cooling, must be considered.

- Cooling of the side slides and cores.

- Cooling element design and selection of standard cooling elements.

- Cooling efficiency and uniformity.

- The impact of the cooling system on the overall mold structure.

YUCO has optimized its mold design for stable performance and faster cycle times. Its simple, linear structure makes it easy to install and maintain. Mold opening and closing utilizes double-check control for high-speed operation.

Another key feature is the excellent cooling lines throughout the cavity and core blocks. YUCO molds utilize circulating water throughout the mold, reducing cooling time, improving production efficiency, and significantly reducing production costs.

High-quality mold materials

Large-volume production requires high-quality steel and excellent processing methods to extend mold life. Supermarket basket molds are made of high-quality mold steel. YUCO Mold always sources steel from genuine manufacturers, such as LKM, SCHMOLZ + BICKENBACH, or Gröditz.

Precautions for mold manufacturing

- Mold dimensions: The mold dimensions must meet the customer’s requirements and the specified injection molding machine model.

- Locating ring: The size of the locating ring should comply with technical requirements, and it should be raised 10mm above the roof. During installation, it should be recessed into the upper fixed plate and not directly placed on the template. It must be fixed with at least two screws.

- Release radius (R): The release radius should comply with standards, with the release radius (R) > forming machine radius (R).

- Polishing: Use 600# sandpaper to polish the surface of the gate bushing and runner to avoid sharp edges.

- Template markings: Each template in the mold frame must have a stamped mold number at the lower right corner. Template numbers should be A0, B0; water inlet and outlet marked IN and OUT; connecting pipes marked L; oil inlet and outlet marked O IN and O OUT. All lettering codes must comply with standards. The external mold appearance can be customized with corroded markings and an “UP” arrow according to customer requirements.

- Protecting the mold bottom: To protect the bottom of the mold, install support feet on the ground.

- Large molds (Over 8 tons): Large molds must have U-shaped grooves or holes for mold locking, corresponding to the fixed position on the molding machine.

- Mold frame: The mold frame must be free of dents, rust, unnecessary rings, water holes, air holes, oil holes, and other defects that affect appearance.

- Chamfering: All plates, hole positions, and mold frame edges should have a chamfer greater than 1.5mm, except in special areas.

- Ring rotation: Ensure that all rings can rotate to the end to maintain balance.

- Ejector plate: Install trash nails below the ejector plate and use the ejector plate for stroke positioning. Screws should not be used as substitutes.

- Support rod area: The support rod area should be 30% of the rear template area between the legs and raised 0.15mm above the mold legs, without interfering with the ejector hole.

- Mold screws: All mold screws should be free of defects such as breakage, stripped threads, etc. Screws of size M12 (inclusive) and above should be of grade 12.9. The length of lifting screws should be at least 1.2 times the diameter of the screw.

- Countersunk hole: The bottom surface of the countersunk hole should be flat, and the screw installation height should not exceed the countersunk hole, with the bottom surface 1-2mm above the plane.

- Ring holes for heavy parts: Parts weighing over 10kg must have corresponding ring holes, with the size and position of the holes conforming to the standard.

- Regarding mold painting: Unless otherwise specified, we spray-paint the mold green. However, in hot, dry regions, we may choose to polish or apply a finish tailored to the customer’s needs.

- Standard mould parts: We use standard mould parts for easier maintenance, ensuring production efficiency and product quality.

Shopping basket material

Most shopping baskets are made of plastic, but polypropylene baskets are easier to clean. This safe, non-toxic, and harmless material can hold a variety of items and has a wide range of uses.

YUCO’s multifunctional shopping basket features fold-down handles for easy stacking. The basket features a unique pattern, making it both beautiful and practical. The thickened wall design provides increased load-bearing, pressure-resistant, and wear-resistant durability. The deep bottom offers a large capacity and is meticulously crafted with no burrs.

With this multifunctional shopping basket, you’ll never need plastic bags again! They’re much more environmentally friendly than plastic bags and can hold up to 10 kg of shopping items. They’re perfect for shopping, laundry, gardening, home maintenance, kitchen storage, camping, beach vacations, and sports.

Mold nameplate

YUCO MOLD affixes a nameplate to the mold, secured with rivets and positioned in a standard manner. This nameplate contains factory information, making it easy for customers to contact us if they encounter any issues. The nameplate also indicates the mold’s completion date, allowing us to easily understand the mold’s warranty period. The nameplate also contains mold base information, helping us select the appropriate injection molding machine.

Quality control process

We understand the importance of quality and precision to our customers. To meet customer needs, we adhere to stringent quality control procedures when producing plastic supermarket shopping basket molds. Every mold order undergoes rigorous inspection by our mold experts.

To ensure the highest quality, we conduct mass production training on plastic mold prototyping and mold operation at least annually. We also make continuous improvements based on customer feedback.

- Pre-delivery mold drawing review to ensure customers have the latest mold drawing version.

- Design confirmation and verification.

- Inspection of raw materials upon arrival.

- Initial mold inspection to ensure quality.

- Electrode inspection using a CMM measuring machine.

- A complete dimensional measurement report is provided after T1.

- Dimension adjustments and re-testing of the mold are performed.

- Coordinate measurement using a CMM machine and projector.

- All shipping documents and spare parts must be complete upon mold shipment.

Why choose YUCO Mold's shopping basket molds?

Are you looking for the highest-quality basket molds? YUCO Mold is a professional basket mold manufacturer and supplier in China, providing high-quality molds that undergo rigorous production control.

Supermarket shopping baskets are a necessity, and the market potential is huge, making them a worthwhile mold. As a supplier of supermarket shopping basket molds, we utilize advanced CAD/CAM/CAE design systems and have accumulated extensive mold manufacturing experience. We are committed to providing high-quality, colorful supermarket shopping basket molds that are highly sought after by customers worldwide at affordable prices.

Simply contact our team of experts, who will assist you throughout the entire process of placing your custom shopping basket mold order. We'll provide detailed information and, if necessary, make recommendations based on your information.

Tel: +86 13586040750