vegetable basket mold

YUCO Mold is a professional plastic vegetable basket mold manufacturer in China with many years of industry experience.

Plastic vegetable basket molds from China manufacturer

- To save money and reduce material waste, you can quickly regrind, melt, and reuse any sprues, runners, or other remaining plastic fragments.

- YUCO Mold boasts advanced production equipment to ensure basket quality. Most production processes are automated, allowing a single operator to control and manage all machines.

- Our staff has extensive international service experience and a wealth of knowledge, providing a comprehensive service experience, from pre-sales communication to after-sales support.

- Our molds offer four to five times higher heat transfer performance than other molds on the market. Customers can minimize production costs by using our molds.

vegetable basket mold specifications

| Parameter / Item | Specification / Description |

| Part Name | Stackable Vegetable & Fruit Crate |

| Part Material | PP (Polypropylene) or HDPE (High-Density Polyethylene) – [Specify Grade, e.g., Food Grade] |

| Part Color | As per customer sample or RAL/PANTONE code |

| Part Dimensions (L x W x H) | [e.g., 600 x 400 x 320 mm] |

| Part Wall Thickness | [e.g., 2.0 mm] (Average) |

| Part Weight | [e.g., 1500 g] |

| Material Shrinkage | To be confirmed based on final material selection (e.g., 1.6% for PP) |

| Mold Type | Plastic Injection Mold |

| Number of Cavities | 1 Cavity |

| Mold Base Standard | LKM, HASCO, DME, or equivalent [Specify Preference] |

| Mold Steel: Core & Cavity | • Option A (Medium Volume): P20, 718H (Hardness: HRC 32-36) • Option B (High Volume): H13, NAK80 (Hardness: HRC 48-52, heat-treated) • Option C (Corrosive Material): S136 Stainless Steel (Hardness: HRC 50-54, heat-treated) |

| Mold Steel: Slider/Lifter | H13 or 2344 with nitriding treatment |

| Mold Steel: Mold Base | S50C or equivalent |

| Guaranteed Mold Life | • P20 / 718H: ≥ 300,000 shots • H13 / S136: ≥ 1,000,000 shots |

| Approx. Mold Dimensions | [e.g., 1100 x 900 x 950 mm] |

| Approx. Mold Weight | [e.g., 6500 kg] |

| Runner System | Hot Runner: Recommended for material saving and improved cycle time. |

| Hot Runner Brand | YUDO, Synventive, Mold-Masters, or customer-specified brand |

| Gate Type & Number | [e.g., 4-6] Pin-Point Hot Gates or Valve Gates |

| Ejection System | Ejector Pins + Stripper Plate + Air Ejection System |

| Cooling System | Optimized cooling channels in core, cavity, and sliders for uniform temperature distribution. |

| Cooling Connector Type | DME or HASCO standard quick connectors. Ports clearly marked. |

| Slider/Lifter Mechanism | Required for handle undercuts. Hardened wear plates on all sliding surfaces. |

| Surface Finish: Cavity/Core | [e.g., SPI-B2 medium polish] or light texture [e.g., MT-11020] as per requirement. |

| Surface Finish: Parting Line | High precision machining, no burrs or flash allowed. |

| Logo/Text Engraving | CNC engraved as per 2D drawing. |

| Suitable Machine Tonnage | [e.g., 750 – 900] Tons |

| Min. Tie Bar Spacing | [e.g., 950 x 950 mm] |

| Max. Opening Stroke | [e.g., 1000 mm] |

| Estimated Cycle Time | [e.g., 35-45] seconds |

| Primary Items | 1 x Injection Mold Final Part Samples |

| Documentation | • Complete Mold Drawings (2D & 3D) • Mold Steel & Heat Treatment Certificates • Final Mold Trial Report |

| Spare Parts | A set of spare parts (e.g., ejector pins, O-rings, heating elements, limit switches). |

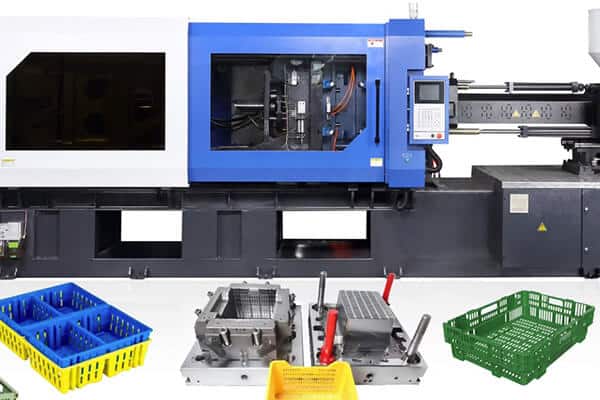

China basket mold manufacturer

Plastic vegetable basket production process

Plastic vegetable baskets are an essential household item, widely used for shopping, storage, and transportation. Behind every durable, stackable, and food-safe basket lies a precisely designed mold.

A plastic basket mold consists of multiple cores, cavities, sliders, and strippers. Plastic is injected into the cores and cavities. The basket is then ejected from the mold using the sliders and strippers. The size and shape of the mold cavity are determined by the customer’s requirements.

demand communication

YUCO MOLD will discuss details with customers to understand their specific requirements for the size, shape, material, and other specifications of the vegetable basket. Samples can also be sent to us by courier.

accurate quotes

Once we confirm the vegetable basket design (including functional details), material, color, and quantity, YUCO MOLD will provide a quote within 24 hours.

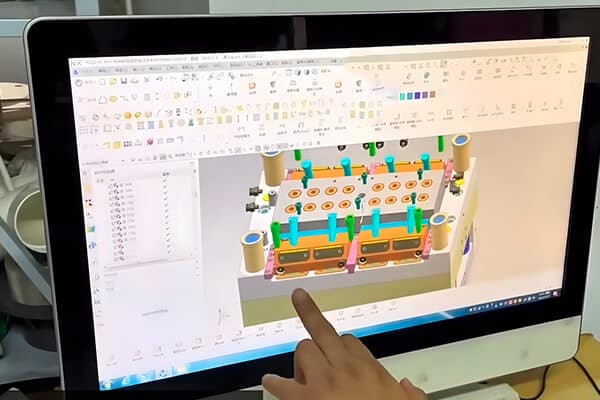

design and development

Based on customer requirements, YUCO MOLD uses CAD software to design molds, creating detailed drawings, and then performs structural analysis and optimization. Factors such as shrinkage and draft angles are considered to ensure final product quality.

Manufacturing and processing

YUCO MOLD selects the appropriate mold material, such as high-strength alloy steel or stainless steel, and then performs cutting and preliminary machining. CNC machines and electrical discharge machining (EDM) are then used for precision machining, ensuring high precision and a smooth surface. We guarantee zero-defect, high-quality products.

Testing and debugging

After assembling and processing the components, YUCO tests and debugs the mold to ensure it can produce vegetable baskets that meet specified specifications. All molds undergo trial runs before shipment to adjust the mold structure and parameters to ensure product quality.

Support

YUCO MOLD delivers the finished mold to the customer and provides technical support and after-sales service to ensure smooth production.

Key features of high-performance vegetable basket molds

Plastic vegetable basket design

- Material: High-quality plastics are typically used, known for their good elasticity and ability to withstand heavy loads. Compared to polyethylene baskets, polypropylene baskets are generally stronger and can handle greater loads.

- Structure: Baskets with reinforced structures or additional support ribs distribute weight more evenly, reducing the risk of deformation. By optimizing wall thickness (1.2 mm to 2.0 mm) and rib structure, YUCO has reduced basket weight by 15% without compromising load-bearing capacity. For example, a 600×400 mm commercial basket can now carry 15kg of vegetables while weighing only 800 grams, reducing shipping costs and carbon emissions.

- Plastic thickness: Thicker plastics are generally stronger and can withstand greater weight. However, this also affects the basket’s flexibility and ease of use. A balance must be struck between durability and practicality to maintain user-friendliness.

- Intended Use. For example, a vegetable basket designed to hold lightweight items like herbs and leafy greens requires different strength than one designed to hold heavier vegetables like potatoes or squash.

- Usage environment. Exposure to extreme temperatures (either hot or cold) can affect the structural integrity of a vegetable basket. High-quality vegetable baskets retain their shape and strength even under harsh conditions, ensuring they can continue to bear weight without risk of damage.

Functional design

The mold must produce a vegetable basket that meets usage requirements, featuring high strength, lightweight construction, and durability, while also providing excellent loading and handling performance. YUCO’s vegetable basket molds are meticulously designed with exceptional precision, achieving tolerances of up to ±0.02 mm (compliant with ISO 2768). This ensures uniform dimensions for each basket, which is crucial for stackability and space efficiency. For example, stackable designs, popular in supermarkets and logistics, can save up to 70% of storage space when nested, reducing shipping costs and warehouse floor space.

Food-grade safety and compliance

With increasing scrutiny of food contact materials, molds must meet stringent regulatory standards. Leading manufacturers design molds that comply with FDA 21 CFR 177.1520 (US), LFGB (EU), or GB 4806 (China), ensuring that vegetable baskets are free of BPA, phthalates, and other hazardous substances. We provide Material Safety Data Sheets (MSDS) and third-party laboratory test reports.

Key compliance features include:

- Smooth surface finish (Ra ≤ 0.8μm) prevents bacterial growth and simplifies cleaning.

- Resistant to acids, alkalis, and food-grade detergents.

- Temperature stability withstands pasteurization or cold chain storage (-20°C to 121°C).

Modular and customizable molds

Mold structures should be easy to process and assemble, avoiding overly complex designs to ensure high production precision and efficiency. YUCO offers modular molds that accommodate interchangeable inserts, allowing for quick design adjustments (e.g., handle shape, drainage holes) without replacing the entire mold. This flexibility is ideal for branded retail baskets.

Economic design

The design should minimize manufacturing costs and maximize production efficiency. It should consider material utilization and ease of processing. Electric injection molding machines with mold temperature control systems can reduce energy consumption by 20-30% compared to hydraulic systems. Furthermore, hot runner molds minimize plastic waste by eliminating runner scrap, reducing material usage by up to 15% per cycle.

Sustainability

Sustainability is no longer optional—consumers and regulators are demanding more environmentally friendly solutions. YUCO is responding by taking the following steps:

Recycled Material Integration: Molds are increasingly compatible with recycled resins, such as PCR-HDPE containing 30% post-consumer content. Advanced mold designs can accommodate the unique flow characteristics of these materials, ensuring consistent part quality while reducing reliance on virgin plastic.

Biodegradable Alternatives: While still a niche market, molds for biodegradable baskets, such as those based on PLA, are gaining traction. These molds require specialized cooling systems to cope with lower melting points, but they align with corporate sustainability goals and the EU’s ban on single-use plastics.

Frequently asked questions

How long does a vegetable basket mold typically last?

The mold is designed to withstand high-volume production and, with proper maintenance, can produce 500,000 to 1,000,000 vegetable baskets. Its service life depends on the material (e.g., PP or HDPE) and production volume. This durability is due to advanced mold steel and heat treatment processes such as quenching and tempering, which resist wear even under continuous use.

What maintenance does the mold require?

Regular maintenance includes cleaning resin residue, checking cooling channels for blockages, and replacing worn parts (such as ejector pins). Annual professional maintenance is recommended to extend the mold’s life.

How long does it take to make a plastic vegetable basket mold?

We offer just-in-time delivery. The lead time for a prototype plastic vegetable basket mold is 4-8 weeks, and for a full production mold is 12-16 weeks. The specific time depends on the complexity of the mold, design requirements, materials used, and production scale. Complex molds require longer design, processing, and commissioning time, while simpler molds can be completed more quickly. Special needs or custom requirements can also affect production schedules. With careful planning and advanced processing technology, we can effectively manage mold manufacturing timelines.

What role does an injection molding machine play in the production of plastic vegetable basket molds?

Injection molding machines play a vital role in the production of plastic vegetable basket molds. Their main functions include the following:

- Melting and injecting raw materials: The injection molding machine heats and melts the plastic raw material (such as polypropylene or polyethylene) into a liquid state. The molten plastic is then injected into the mold cavity under high pressure, ensuring that the molten plastic evenly fills every part of the mold.

- Molding and curing: After the liquid plastic is injected into the mold cavity, the mold is maintained at a specific temperature and pressure to allow the plastic to quickly cool and solidify, forming the desired basket shape. The injection molding machine’s control system precisely regulates temperature, pressure, and injection speed to ensure product quality.

- Mold opening and demolding: The injection molding machine automatically controls the opening and closing of the mold. After cooling and solidification, the machine opens the mold and removes the finished basket from the mold using a robotic arm or other automated equipment. This process is fast and efficient, making it suitable for large-scale production.

- Cycling production: Injection molding machines enable efficient cyclic production, with each production cycle (including melting, injection, curing, and part removal) typically taking only seconds to minutes. Efficient cycle production significantly improves production efficiency and reduces costs.

The injection molding machine precisely controls every production step, ensuring consistent shape, size, and quality of the plastic baskets. This not only improves production efficiency but also enables the manufacture of complex shapes and intricate structures to meet diverse market demands.

Why choose YUCO Mold's vegetable basket molds?

Are you looking for the highest-quality vegetable basket molds? Then YUCO Mold is the ideal choice. We specialize in custom basket mold production and have over 20 years of experience.

As a leading manufacturer and supplier, YUCO also accepts custom orders. Our highly creative design team is capable of designing and manufacturing molds to meet specific size, shape, and functional requirements. You can also customize your logo on the product surface, packaging, color box, or carton.

YUCO Mold has not only earned a strong reputation in the Chinese market, but has also actively expanded its business overseas, establishing long-term partnerships with many well-known companies. No matter where you are in the world, we welcome you to join us and work together to create a bright future for your business!

Tel: +86 13586040750