bucket mold design & manufacturing in China

At YUCO MOLD, we are committed to providing one-stop solutions for custom-designed bucket molds, ensuring molds are manufactured with high precision and efficiency.

The advantages of making plastic bucket molds in YUCO

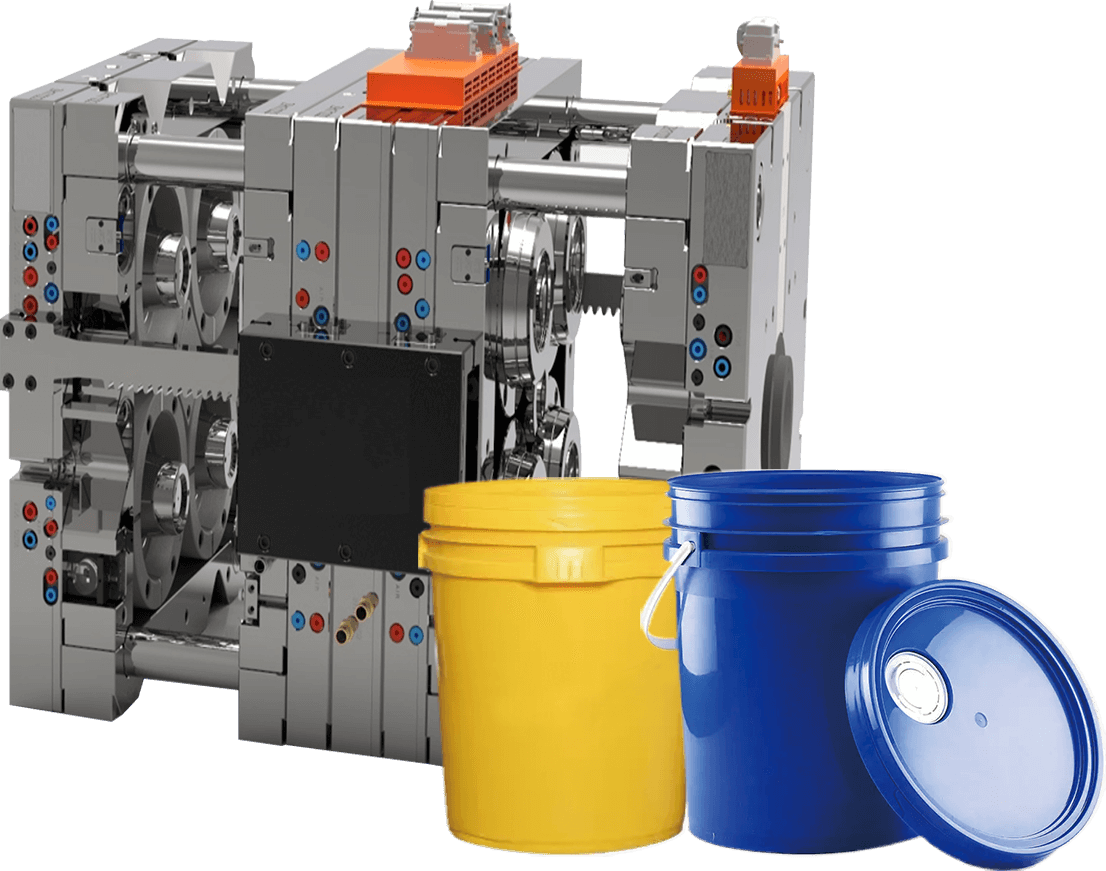

YUCO MOLD offers you more than just bucket molds - it's comprehensive, impactful solutions. Whether you need a robust multi-cavity system for mass production or a dedicated thin-walled pail design, YUCO MOLD is your go-to resource for precision molding solutions.

- High precision: Our molds ensure consistent bucket dimensions, reducing scrap and defects.

- Custom designed solutions: We offer a comprehensive range of design options for drums of all shapes and sizes. Whether you need a standard cap, an integrated handle, or innovative features such as in-mold labelling (IML), our team of experts can seamlessly integrate them into your custom mold design.

- Mold flow analysis: Mold flow analysis technology allows us to simulate the injection molding process of plastic drums, detecting potential problems early on and optimising the mold design.

- Instant Quotation: We have optimised our quotation process for quick response. All you need to do is request a quote and you will receive it immediately. We strive to start your project in the shortest possible time.

Customized plastic bucket molding

YUCO MOLD provides one-stop custom bucket injection molding service for global customers. This includes customising the size, shape, application and material of plastic buckets.

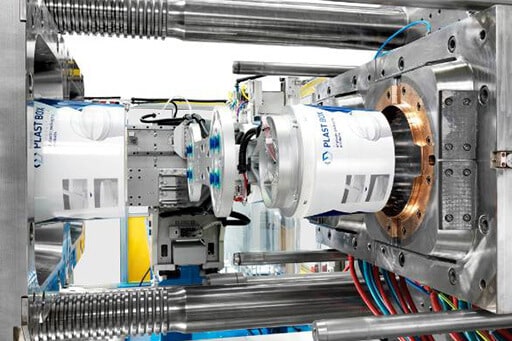

YUCO'S bucket mold manufacturing service

YUCO offers a comprehensive bucket mold manufacturing service, specialising in creating high quality, durable molds for all types and sizes of buckets. Utilising advanced CAD/CAM technology and precision machining equipment, YUCO can manufacture bucket molds to tight tolerances and complex designs.

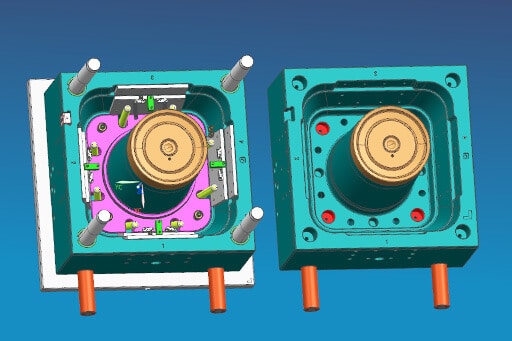

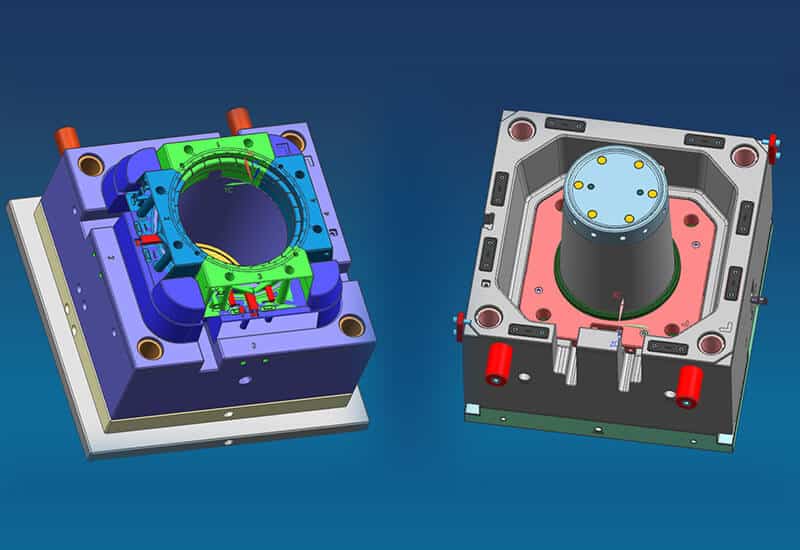

Mold design

Mold design is the first step in the manufacturing process. Our engineers utilise advanced Computer Aided Design (CAD) software to take precise measurements and tailor the mold to the customer's specifications.

Selection of mold steel

In the manufacturing of bucket molds, selecting the appropriate mold steel is critical to ensure durability, efficiency, and quality of the final product.

Bucket mold manufacturing

Once the design and materials have been finalised, the next stage is machining. We use state-of-the-art CNC machines that are not only highly accurate, but also capable of automated cutting, forming and drilling. It ensures the machining precision of each mold part.

Adding cooling channels

Cooling channels ensure even cooling of the mold during the injection molding process of the plastic bucket, thus preventing defects such as warping or shrinkage of the final product. The design of these channels is optimised to reduce cycle times and improve the overall quality of the paint pail.

Polishing and surface treatment

This step is crucial as it directly affects the beauty and quality of the surface finish of the produced paint buckets. We use a variety of tools and abrasives to carry out a meticulous polishing process to ensure a smooth and flawless surface.

Mold testing and adjustment

Before going into full production, each new mold undergoes rigorous testing. This involves injecting molten plastic into the mold to produce samples of buckets. These samples are then checked for defects or inconsistencies and adjusted as needed.

Brighten up your next plastic bucket project!

If you are working on a plastic bucket project, contact us today! Providing first-class solutions and innovative approaches to your needs.

Bucket mold design service

Optimise your bucket production with our comprehensive bucket mold design service. We specialise in designing high quality, high precision molds for every part of the pail, including the lid, the bucket handle and the bucket itself.

Our experienced design team uses the latest technology and industry best practices to ensure that your molds deliver optimum performance, durability and cost-effectiveness.

Whether you require a standard design or a bespoke solution, our bucket mold design services can streamline your manufacturing process and maximise the value of your investment.

Gate

The gate is the part of the mold that controls molten plastic flow into the cavity. The gate is usually located on the perimeter of the mold and can be either opened or closed. The type of gate to use depends on the shape of the bucket. The gate position of the bucket mold is relatively fixed, in the center of the bottom of the bucket.

The ejector system

The ejector system is responsible for removing the molded bucket from the cavity once it has cooled down and solidified. The ejector system typically consists of an ejector pin connected to an ejector plate. The ejector pin pushes against the back side of the molded bucket while the ejector plate pulls it away from the front side. This action causes the molded bucket to be ejected from the cavity so that it can be removed from the mold altogether.

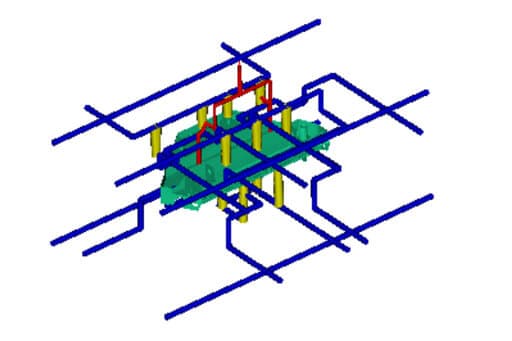

Design of the cooling line

The design of the bucket mold cooling line should be determined according to the bucket size and wall thickness. If the cooling line hole is too small and the cooling is not timely, it is easy to cause the mold not to cool in time, resulting in thermal corona on the product’s surface and affecting the product’s appearance.

Therefore, adopting a multi-circuit cooling design is necessary, which can not only cool the mold quickly but also cool it uniformly.

The runner system

The runner system is a network of channels that transport molten plastic material from the sprue to the cavities of the mold. The runner system typically consists of two parts: cold and hot runners.

More recently, most buckets are hot runner injection molded for productivity and cost-effectiveness. There are two main types of hot runners to choose from. One is a hot runner or hot runner, needle valve. The other thing is the choice of hot runner brands, such as Husky, domestic hot runner, Yuduo, and Master.

The use of hot runner sprues to produce plastic buckets has the following advantages

- No mold rise, mold clamping, overflow, gapping, etc.

- Uniform wall thickness of the finished barrel, deviation <0.04mm.

- High finished product rate, up to 99% or more.

- Shorter forming cycle.

- Cost reduction.

High quality mold steel for bucket mold

The quality of your bucket molds directly impacts the quality and longevity of your final product. That’s why selecting the right mold steel is crucial. Our bucket molds are crafted with high-strength mold steel, ensuring they can endure the pressure and heat of the molding process.

- P20 steel is commonly used in the production of pail molds due to its high durability and strength.

- 718H steel is commonly used in the manufacture of cores and cavities for pail molds.

- Beryllium Copper (BeCu) is ideal for the production of paint bucket molds due to its excellent thermal conductivity and high strength.

They need to be tested by a spectrometer to ensure that it is the correct steel grade we ordered before machining. The choice of these steel grades depends on the customers’ cost, budget, and service life.

High quality plastic materials for plastic buckets

Our buckets are crafted from durable HDPE, LDPE, or ABS, ensuring lasting strength and stability. Handles and lids are injection molded using lightweight, easy-to-mold PP and PE plastics.

HDPE

Choosing HDPE for our plastic bucket molds ensures robust construction and excellent durability thanks to the polymer's inherent strength and versatility.

LDPE

LDPE can withstand temperatures up to 100°C and, although not as strong as HDPE (High Density Polyethylene), produces more durable drums.

ABS

ABS is resistant to corrosive substances and physical forces, and has a low melting temperature, making it an ideal material for the manufacture of plastic buckets.

Meet the complexity of the bucket molding process

YUCO offers a blend of complex technologies in the bucket molding process in order for you to meet different market needs and functions.

Overmolding

Overmolding is used to create buckets with higher strength and multiple material properties.

In-mold labelling (IML)

In-mold labelling (IML) incorporates decoration into the injection molding process by placing the label into the mold and then injecting plastic behind the label to permanently embed the label into the inside of the product.

Two shot injection molding

Two shot injection molding produces seamlessly integrated two-colour or two-material buckets by injecting two different materials into the same mold, either continuously or simultaneously, without the need for post-mold assembly.

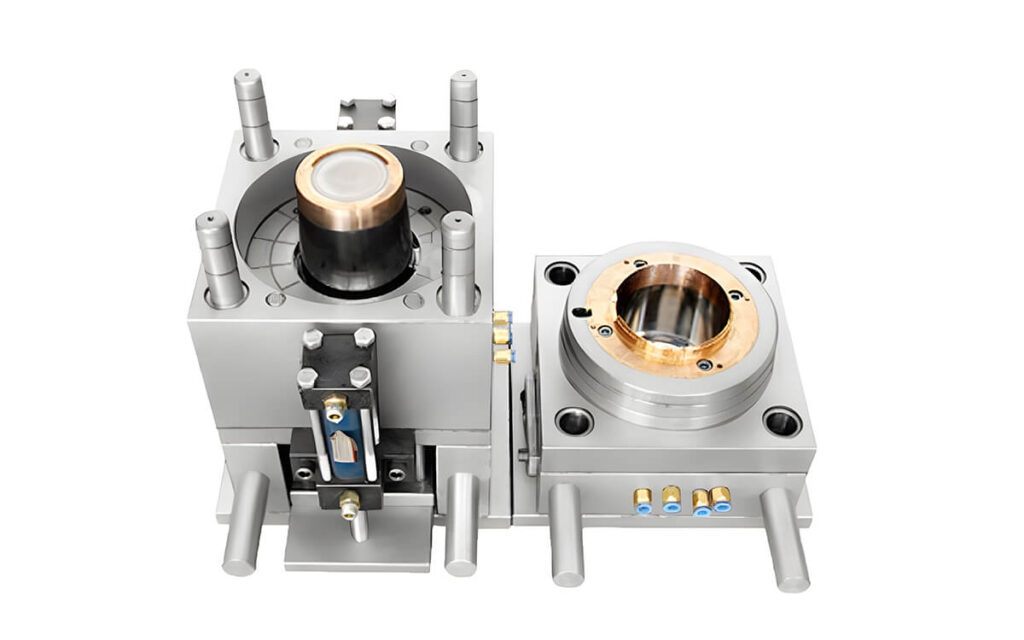

Case study: 10L paint bucket mold

In this case study, we undertook the full development and manufacture of a customised 10L paint bucket mold, from initial mold design through to manufacture and successful trial molding.

| Name | 10L paint bucket mold |

| Hot runner | 1 drop with “HOTSET” heating coil |

| Cavity steel for paint pail mold: | DIN 1.2311 + beryllium copper |

| Core steel | DIN 1.2311 + beryllium copper |

| Plastic material | HDPE |

| Cycle time | 19 seconds (high speed injection machine) |

| Mold life | 1 million |

FAQs about bucket mold business

What is the purpose of the bucket mold?

The purpose of a bucket mold in injection molding is to shape molten plastic or other materials into a bucket product. Bucket dies typically consist of two halves that fit together, with cavities designed to form the desired shape as the material is injected and cooled.

Injection molding is a cost-effective method of mass-producing buckets with little or no labor. Without mold, manufacturers could not mass-produce specific shapes and designs. Molds are also essential in creating specialized designs or imprints on plastic items, adding functionality and visual appeal.

How long does it take to design and create a custom bucket mold?

Creating a custom bucket mold requires careful planning and precision execution.

The first step is to gather all necessary specifications, such as the bucket’s dimensions and desired design elements. From there, our experienced designers will create a CAD drawing for the mold. This process typically takes 1-2 weeks, depending on the complexity of the design. Once the client approves the drawing, it’s time to begin machining the mould using high-quality industrial equipment.

The actual machining process can take anywhere from 2-4 weeks, depending on the design’s complexity. Our team closely monitors progress throughout this process to ensure that we meet all quality standards and deliver a top-notch final product.

Altogether, creating a custom bucket mold usually takes 4-6 weeks from start to finish.

Get started on your plastic bucket project today!

As the leader of bucket mould supplier in China. YUCO Mold has more than 20 years of bucket mold manufacturing experience and serves the world.

If you are interested in placing an order for a custom bucket mold at YUCO Mold, the first step is to fill out our online quote form. This will allow us to gather information about your unique project requirements and provide you with an accurate price estimate. Once the quote is approved, we will begin designing and creating a mold prototype before moving on to production.

Our team will also work with you throughout the entire process to ensure that the final product meets all your specifications. In addition, each mold undergoes rigorous testing before being shipped to customers, guaranteeing its durability.

Tel: +86 13586040750