Oil bucket mold

YUCO designs, manufactures and supplies any plastic oil bucket mold, including oil bucket molds of different materials and sizes, to meet the needs of each customer.

Plastic oil bucket molds from China manufacturer

- The special oil bucket machine uses a special screw and barrel, and has a fast mold opening function, which ensures mold opening accuracy while shortening the molding cycle

- Our commitment to quality makes us stand out from the competition. The oil bucket cover is snapped on, and the plastic bucket is one-time injection molded. The barrel body and the barrel cover fit tightly, which is stable and thick.

- YUCO is a company integrating R&D, production and sales, providing a one-stop oil bucket solution. We can also assemble oil buckets of various sizes (lids, barrels and handles) and provide packaging services.

- We have a strict quality management system, perfect mold design, advanced production and processing technology, reasonable price, and excellent on-time delivery capabilities.

oil bucket mold specifications

Oil bucket molds are molds designed specifically for producing plastic oil buckets through injection molding, used to hold and store oil, lubricants, paints, etc. Manufacturers create these tools to produce precise design specifications that meet industry requirements. The choice of mold requires an understanding of the types available, as this will help make better decisions.

- Single-cavity molds: produce barrels individually, best suited for minimal manufacturing operations.

- Multi-cavity molds: produce multiple barrels at the same time, improving efficiency for large orders.

- Stacking molds: provide a special design that can be stacked, improve space efficiency and speed up production time.

| Feature | Description | Options/Variations |

|---|---|---|

| Bucket Capacity | Common sizes: 5L, 10L, 18L, 20L, 25L, 30L, 50L, 200L (Custom sizes available upon request) | Specific capacities can be tailored to customer needs. |

| Material of Bucket | High-Density Polyethylene (HDPE), Polypropylene (PP), (other materials available upon request – please specify) | Material selection based on application and desired properties. |

| Mold Material | High-quality steel: P20, D2, H13 (Other mold steels available upon request – discuss with our engineers for specific needs) | Choice of mold material influences mold life and product quality. |

| Mold Cavity | Single cavity, Multi-cavity (e.g., 2, 4, 8, etc.) | Cavity number influences production efficiency. |

| Mold Design | Stack mold, Hot runner mold, Cold runner mold | Mold design tailored to maximize production efficiency and product quality |

| Gate Type | Pin-point gate, Submarine gate, Edge gate, Sprue gate (Optimized gate design for minimal gate vestige and efficient material flow) | Gate selection impacts cycle time and aesthetic finish. |

| Ejection System | Ejector pins, Stripper plate, Air ejection (Customized ejection systems available to ensure flawless part removal) | Selection depends on bucket design and material. |

| Cooling System | Optimized cooling channels for uniform cooling and reduced cycle times. | Efficient cooling critical for consistent quality and fast cycle times. |

| Surface Finish | Textured (e.g., diamond, matte, etc.), Smooth, or Polished (Specific finishes can be customized per customer requirements) | Surface finish influences the final appearance of the oil bucket. |

| Tolerance | Tight tolerances maintained to ensure consistent and accurate part dimensions. (Provide specific tolerance requirements for precise quotation) | Precision manufacturing ensures consistent product quality and compatibility. |

| Lifespan | High mold lifespan ensured through robust design and high-quality materials. (Estimated lifespan provided based on material and specifications) | Durable molds minimize downtime and maximize return on investment. |

China bucket mold manufacturer

oil bucket molding processing

After the plastic oil bucket injection mold is ready, the molding process includes the following basic steps:

- Step 1, preparation before molding: the preparation before injection molding mainly includes: raw material appearance and process performance inspection, preheating and drying; cleaning or replacement of the injection molding machine barrel; reasonable selection of release agent.

- Step 2, injection molding process flow: feeding-plasticization-injection-pressure holding-cooling-demolding.

- Step 3, post-processing of bucket after injection molding: post-processing can eliminate the internal stress of bucket, improve performance, improve dimensional stability, and stabilize color. Bucket post-processing includes annealing and humidity adjustment.

How to buy injection oil bucket mold from China: A step-by-step guide for beginners

Purchasing oil bucket mold from China will enhance your production capabilities. You can get high-quality molds through the right sourcing methods. YUCO Mold has put together a complete guide that covers all the necessary steps to complete this process effectively.

Define your needs

Before you start contacting suppliers, you need to make your oil bucket mold clear to them. Consider the following:

- Define the dimensions of the production oil bucket you need to create.

- Note the features to determine if the product includes handles or stacking capabilities.

- Can you tell us how many injections molded parts you need per year, month, or day?

- What plastic material is used?

- The tonnage or capacity of the existing injection molding machine?

- Are there any special requirements for the brand of parts for the custom injection mold?

If you have a 3D design or 2D detailed drawing of the plastic part, please send it to us. We will modify it according to your requirements. If you only have a plastic sample, please mark the dimensions on the picture and send us a clear picture so that we can provide some professional suggestions to help improve the product details. Once both parties confirm the needs, we will provide a cost estimate and project completion timeline.

Research suppliers

The next step is to find a reputable Chinese oil bucket mold manufacturer. Online platforms such as Alibaba, Made-in-China.com, and Global Sources are the preferred resources for finding quality companies. Consider the following:

- Focus on those businesses that have received positive feedback from past customers.

- Confirm that the supplier holds the certifications required for quality assurance.

- Evaluate the supplier’s experience in oil bucket mold production.

While contributing our decade of experience and expertise to our customers, we also provide them with skilled, knowledgeable, and dedicated staff to manufacture oil bucket mold.

Get price estimates and samples

Contact your chosen oil bucket mold supplier to discuss your estimate needs. Specifics include:

- Get complete information about mold pricing from potential suppliers.

- When contacting suppliers, ask about production lead times.

- Understand the additional charges for shipping the mold to your specified shipping address.

Our exceptional programs include affordable, precision-fitting handcraftsmanship, fast lead times, and reliable support services. Our craftsmen create reliable oil bucket molds at prices below the market average.

Evaluate communication and support

When working with international oil bucket mold suppliers, good communication is essential. When submitting questions, be sure to test their response speed. Reliable suppliers will:

- Provide quick responses, indicating excellent customer support.

- Show a willingness to help resolve any issues and demonstrate reliability.

- Ensure clear communication to avoid misunderstandings.

Our experienced team of professionals is committed to providing the highest level of personalized customer service to our customers. Our company provides excellent sales staff for professional and timely communication. We assist you from planning and design to final production delivery. We have a team of high-level designers and use advanced machines such as CNC DMG EDM CMM. The factory is equipped with state-of-the-art machines to meet the various needs of injection molds.

If our products have quality problems during the warranty period, we will replace the broken parts for you free of charge; in addition, if you encounter any problems when using our molds, we will provide you with professional communication.

Negotiating terms

Before finalizing the agreement, please review all terms of the order carefully with your selected supplier. Discuss:

- Available payment methods include bank transfer, PayPal and letter of credit.

- You need to obtain the exact date of the mold.

- What warranty coverage is included when purchasing the mold.

Our reputation for excellence is based on providing the best results, regardless of the size or complexity of the project.

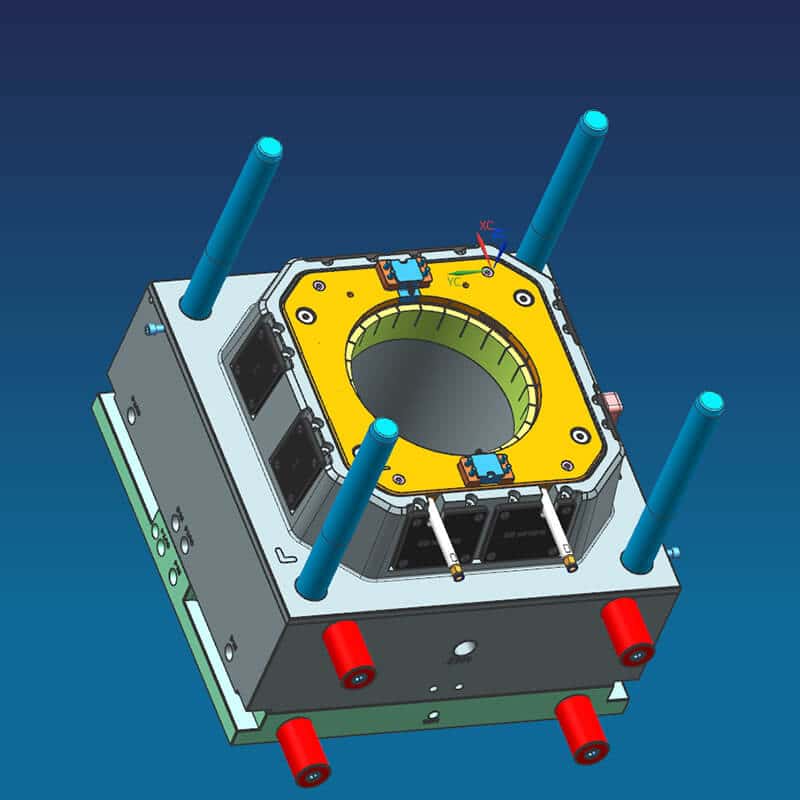

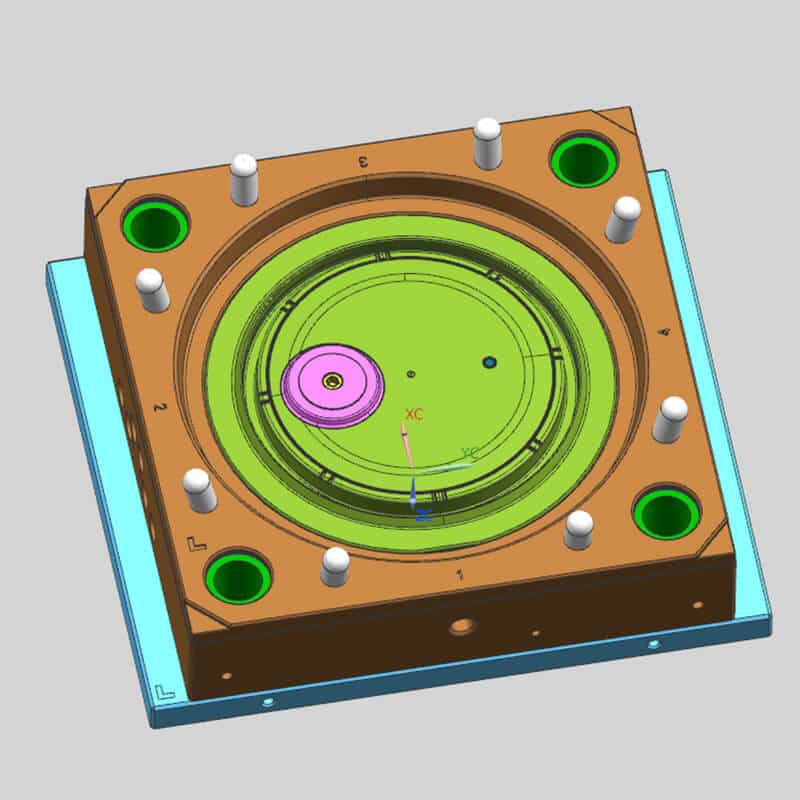

Plastic oil bucket mold design capabilities

Our team has 10 years of experience in bucket mold design and manufacturing, ensuring the mold structure is perfect.

We design the mold based on the confirmed product, including: calculating the number of cavities of the injection mold according to the size of the machine; determining which steel and which gate to choose; selecting hot runners, hydraulic cylinders, etc. from well-known brands;

We can produce oil containers of various sizes, from small oil tanks to large oil drums for industrial use. The mold can be customized to meet specific size and shape requirements.

An efficient cooling system is integrated into the mold to ensure that the plastic material is evenly cooled and solidified, resulting in a high-quality oil bucket.

In addition, we also focus on the details of the plastic paint bucket, such as the slider design may not be required when the bucket is direct and simple; mechanical ejection design for automatic falling or collection by robots; certain fixed designs for further heat transfer.

Monitor oil bucket mold production

Maintain regular communication with oil bucket mold suppliers from the start of production to completion. Regular updates can help you:

- Monitor production progress through regular inspections.

- Report all problems as soon as they occur to prevent them from expanding.

- Hire a third-party inspection service to check quality before shipment.

After the mold design is confirmed, we start making the mold, cutting steel, CNC machining, polishing, sampling, etc. Depending on the desired finish of the oil bucket, the mold can also be finished with various surface treatments, such as polishing or texturing, to achieve the desired look. Every step of the production is rigorously tested to ensure you get excellent workmanship. Mold process photos are updated weekly to customers so that they can monitor our production process.

Mold testing and samples

Before the mold is delivered, we will arrange at least 3 mold tests to ensure that the mold runs smoothly and obtain high-quality bucket samples (size, weight, wall thickness). If it meets customer requirements, if everything is OK, arrange samples for customer approval.

Arrange shipping

Once the sample is approved, we will arrange for shipment. Discussion:

- Evaluate various shipping solutions to determine price and delivery time.

- Understand the import tariffs in your country to avoid unnecessary expenses.

- Verify the shipping time of the supplier.

We will ship the mold within 7 days. By sea or air, the nearest port – Ningbo/Shanghai. Our team takes pride in completing each project on time, allowing you to focus on the work that really matters.

Inspection after arrival

After delivery, please conduct a comprehensive inspection of the mold to confirm that it meets your initial requirements. Use your production process to evaluate the effectiveness of the products you purchase. If you have any questions, contact the supplier immediately to resolve them.

The steps outlined here can help you obtain high-quality oil bucket mold from China, thereby improving production efficiency. Your company can meet the needs of Chinese companies by developing strategic planning and communicating effectively with them.

YUCO Mold: A first-class oil bucket mold manufacturer

Choosing YUCO MOLD as your paint bucket mold supplier will be of great benefit. Here are the reasons:

- Budget-conscious solutions without compromising on quality.

- Years of mold manufacturing expertise.

- Top-notch technology and efficient production processes.

- Ability to fulfill large or small orders.

When YUCO MOLD developed its oil bucket mold, protecting the planet was always our top priority. We work towards three goals: energy-efficient production, material recycling, and reducing material waste. By choosing our eco-friendly molds, you will be doing your part to build a greener future - isn't that great?

Tel: +86 13586040750