injection molding

YUCO provides professional injection molding services for prototypes and production. Precision, quality and efficiency exceed expectations. Turn your ideas into reality in no time.

Your one-stop shop for high-quality injection molding in China.

At YUCO, we specialize in providing comprehensive injection molding services tailored to your needs. As a leading injection mold manufacturer in China, we pride ourselves on providing high-quality injection molded parts, injection molds with short molding cycles, and competitive prices. Whether you need mass production or prototyping, our experienced team of engineers and technicians can provide efficient solutions. Here are what sets us apart:

- We use state-of-the-art injection molding machines, molds, and molding technologies to ensure precision and efficiency for every project.

- Our team is well-versed in processing a wide range of materials, including a wide range of thermoplastics, thermosets, and specialty materials.

- We use our expertise and resources to optimize production efficiency, reduce costs, and improve quality.

- Timely delivery, striving to provide fast turnaround times without compromising quality, accelerate your product development cycle.

- Strict quality control processes and certifications, such as ISO 9001, ensure consistent high-quality output.

- We are committed to providing excellent service and support throughout your project. It also includes additional value-added services such as assembly, packaging, and logistics support.

Diverse injection molding capabilities

YUCO is proud of this. In addition to standard injection molding, our expertise extends to a variety of other specialized injection molding capabilities to meet complex designs and special requirements.

overmolding

Learn about YUCO's overmolding services: benefits, applications and processes. Partner with us to enhance your products.

thin-wall injection molding

China leading thin-wall injection molding service provider. YUCO offers advanced technology, professional engineering design and customized solutions to meet your thin-wall needs.

two-shot & multi-shot injection molding

Two-shot and multi-shot injection molding have transformed injection molding. These technologies enable the integration of multiple materials or colors into a single part, opening up scope for complex geometries, better functionality and aesthetic appeal.

in-mold labeling (IML)

Here, YUCO mold will take an in-depth look at in-mold labeling (IML), introducing its benefits, materials, processes, and more to achieve durable, high-quality results.

Contact our injection molding team now!

YUCO injection molding service process

Partner with YUCO for your injection molding needs, ensuring you get the job done from initial concept to final product. We’ll guide you through every step of the process:

01

contact YUCO

02

Get a quote

03

DFM & Approvals

04

Receive prototype samples

05

Produce molds & deliver parts

06

after-sales service

contact YUCO

Start by contacting our team of experts. Provide us with detailed project requirements including:

- Product design files (CAD, drawings)

- Material specifications

- Expected quantity requirements

- Required lead time

- Intended application and any specific performance requirements

Our team of experts will review your requirements and may ask follow-up questions to ensure we fully understand your needs

Get a quote

Based on the information you provide, we will quickly provide a comprehensive and competitive quote outlining all relevant costs, including tooling costs, per-part pricing at different production volumes and any additional service charges required (e.g. secondary operations, assembly). We ensure transparent pricing with no hidden fees.

DFM & Approvals

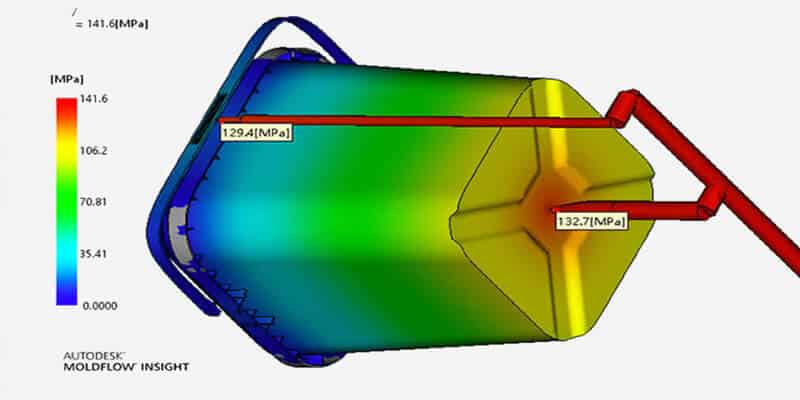

Before production begins, our engineering team conducts a comprehensive Design for Manufacturability (DFM) analysis. This analysis will:

- Identify potential issues in part design that could impact moldability or part quality

- Recommend optimizations to enable efficient and economical injection molding

- Ensure that the part design meets all functional requirements

You will then receive a detailed DFM report with recommendations, and upon approval, we will proceed with detailed design

Receive prototype samples

Once your design is complete, we will produce a set of prototype samples using our advanced rapid tooling capabilities. This allows you to physically evaluate the design, function, and aesthetics of your part before committing to full production. We encourage your feedback on the prototypes, and we will make any necessary adjustments to the tooling or process to guarantee your complete satisfaction.

Produce molds & deliver parts

Once you approve the prototype, we’ll begin production of the final mold. We’ll then use high-speed injection molding machines to manufacture your parts to the highest standards. Our quality control team will monitor the production process and maintain clear communication with you to keep you informed of progress and expected delivery dates. We’ll package your parts securely to prevent damage during shipping. For ongoing orders, we’ll develop a production and delivery schedule that meets your needs

after-sales service

Our commitment to your satisfaction goes beyond delivering your parts. We provide comprehensive after-sales support, including:

- Technical assistance with part integration or assembly

- Scheduled mold maintenance and repairs

- Reorder process for repeat orders

- Continuous improvement recommendations to reduce costs or improve quality

Applications for injection molding

Injection molding is a versatile manufacturing process that can be used to produce a wide range of products across a wide range of industries. YUCO already has injection molding capabilities for a wide range of industries.

01

Consumer Electronics

02

Medical Industry

03

Consumer Goods

04

Packaging Industry

05

Aerospace & Defense

injection molding company

FAQs for injection molding

What is injection molding?

Injection molding is a manufacturing process that produces parts by injecting molten material into a mold cavity. Here is a breakdown of the steps:

- Melting: The raw plastic pellets are first dried and mixed with colorants if necessary. Inside the machine, the plastic pellets are heated and mixed until the resin is semi-liquid.

- Injection: The liquid is injected into the mold’s gate and runner system through a nozzle under high pressure.

- Cooling and Solidification: The molten material fills the cavity, forming the shape of the part. It then cools and hardens inside the mold.

- Ejection: After the material solidifies, the mold opens, and an ejector pin pushes the molded part out.

What are the advantages of injection molding?

- High-volume production capabilities: Injection molding is well suited to mass production, producing thousands of identical parts quickly.

- High precision and repeatability: Injection molding can produce parts with very tight tolerances and consistent quality, ensuring that every part is the same.

- Wide range of materials: Injection molding can be used with a wide range of materials, including thermoplastics, thermoplastic elastomers, and even some metals, offering a wide range of material properties.

- Design flexibility: Injection molding can easily produce complex and precise shapes, including undercuts and intricate details, thanks to the use of molds customized for each part.

- Low labor cost and high efficiency: The injection molding process can be fully automated, requiring minimal human input, saving time and labor costs.

What should be paid attention to during injection molding?

In injection molding, to efficiently produce high-quality parts, the following factors should be considered:

- Material selection: Select the appropriate raw materials based on the characteristics of the product and the intended application requirements.

- Mold design: Careful mold design is essential for part quality and mold life, and YUCO’s injection molds can reduce defects and improve efficiency.

- Injection molding process parameters: Appropriate temperature, pressure, and injection speed all affect the quality of the product.

- Cooling time: Ensure sufficient cooling time to prevent warping or defects.

- Quality control: Testing and inspection at each stage help ensure product consistency.

- Mold maintenance: Clean and maintain the mold regularly to prevent problems and extend its service life.

Advantages of plastic injection molding

Plastic injection molding is a plastic manufacturing process that allows for the mass production of high-quality parts. It is commonly used for small to large-volume production.

- Low-cost, high-volume production

- Excellent part appearance and surface finish

- Reproducible

- Complex parts

- Low scrap rate

- Wide range of thermoplastic and thermoset materials are available

YUCO MOLD - Get first-class injection molding services

Turn your ideas into reality with YUCO's professional injection molding services. Whether you need a prototype or high-volume production, our team of experts and innovative technology can deliver results that exceed expectations.

Years of experience in the injection molding industry. We provide free expert consultation for every injection moulding order, including advice on mould design, material and finish selection for end-use applications, and shipping methods. Let us be your trusted manufacturing partner. Contact us today for a free consultation and quote.

Tel: +86 13586040750