Mold steel can corrode in a variety of ways as it is exposed to extreme environments, cooling systems, and specific chemicals during the molding process. Mold steel corrosion is a common challenge in the injection molding and can adversely affect mold life, molded part quality, and overall productivity.

This article examines mold steel corrosion, explores its various types, analyzes its causes, and proposes effective prevention and remediation strategies. By understanding these aspects, you can better protect your mold investment and ensure that the mold maintains optimal performance throughout its service life.

Understanding mold steel corrosion

What is mold steel corrosion?

Corrosion in mold steel manifests as the gradual deterioration of the metal through chemical or electrochemical reactions with the environment. This process occurs when the steel surface interacts with moisture, oxygen, and other corrosive agents in the manufacturing environment, resulting in the formation of iron oxide and other compounds that weaken the metal structure. Here are a few common types of mold steel corrosion:

- Uniform corrosion is the most common form of mold steel corrosion, characterized by consistent and uniform corrosion across the entire exposed surface. The surface typically appears rough and discolored, with a layer of rust or oxidation products covering the affected area.

- Pitting is a particularly insidious form of localized corrosion that forms small, deep holes in the mold steel surface. This type of corrosion begins at a weak point and progresses downward into the metal. Despite its small surface, this hole can cause significant damage by acting as a stress concentrator and potential crack initiation point.

- Crevice corrosion occurs in confined spaces where small amounts of stagnant solution become trapped, such as under gaskets, within joints, or between mating surfaces. This type of corrosion is particularly problematic in mold assemblies where multiple components are joined together.

- Stress corrosion cracking (SCC) is caused by the combined effects of tensile stress and a corrosive environment. This dangerous form of corrosion can lead to sudden, catastrophic failure with little warning.

- Intergranular corrosion attacks the grain boundaries of a metal. This corrosion preferentially affects the areas between individual grains in the metal’s microstructure, causing the material’s bond strength to weaken.

Adverse effects of mold steel corrosion

As corrosion progresses, it can cause dimensional changes, surface roughness, and the formation of pits or cracks, ultimately affecting the quality of the manufactured product.

The effects of corrosion on mold steel extend far beyond surface damage. In severe cases, corrosion can cause the mechanical properties of the mold to deteriorate, impairing its ability to withstand the high pressures and temperatures inherent in molding operations. This deterioration often results in a significant reduction in mold life, leading to expensive downtime and replacement costs.

Therefore, understanding the causes of mold steel corrosion is critical to maintaining production efficiency and product quality.

causes of mold steel corrosion

Many factors contribute to mold steel corrosion. Understanding these causes is critical to preventing mold degradation. Here are the main causes of mold steel corrosion:

Physical factors

Mechanical wear during normal operation removes the protective surface layer and exposes the mold steel directly to the corrosive elements. Plastic materials, especially those with fillers or reinforcements, can cause microscopic surface damage that can serve as starting points for corrosion. Microcracks, porosity, and other surface defects can trap moisture and corrosive agents, creating localized areas that accelerate the corrosion process.

Environmental factors

Environmental conditions, especially exposure to moisture, humidity, and temperature fluctuations, are the most common causes of mold steel corrosion. These conditions can cause oxidation and rust on the mold surface, weakening the material over time.

- Moisture and humidity: When molds are exposed to moisture or humidity, water vapor can condense on the steel surface, causing rust.

- Temperature fluctuations: Rapid temperature changes, such as during the injection molding process, can cause condensation on the mold surface. This moisture, combined with oxygen, can accelerate the oxidation process, leading to corrosion.

- Airborne pollutants: Industrial atmospheres often contain corrosive gases such as sulfur dioxide and other pollutants that combine with moisture to form corrosive acids, which accelerate the corrosion process.

Chemical reactions

During the molding process, molds are often exposed to chemicals that can corrode the steel surface.

- Corrosive byproducts: Certain plastics, such as PVC, release acidic or corrosive byproducts during the molding process. These chemicals react with the mold steel. If exposed to these chemicals for a long time without proper maintenance, corrosion will accelerate.

- Cleaners and lubricants: Certain cleaners and lubricants used in mold care can quickly break down the protective oxide layer on the steel surface.

Electrochemical reactions (galvanic corrosion)

Galvanic corrosion occurs when two dissimilar metals come into contact with each other in an electrolyte, such as water or other conductive solutions. When the components of a mold are made of dissimilar metals and moisture is present. In this case, an electrochemical reaction can occur. This causes one of the metals to rust faster, usually especially severe at the interface between the dissimilar metals.

Poor mold steel quality

Mold steel is more susceptible to corrosion if it is severely lacking in alloying elements such as chromium, nickel, or molybdenum. These ingredients form a passive oxide layer that protects the steel from rusting. Steel that requires proper heat treatment may have internal stresses or irregularities that make it more susceptible to cracking and corrosion. Improperly treated steel will have inconsistent structural integrity, which reduces its ability to resist corrosion.

Contamination in the cooling system

Contaminants in the cooling system can also increase mold steel corrosion. Cooling channels typically carry water or coolant that contains minerals, salts, or impurities that can cause corrosion within the mold cooling channels. If not maintained regularly, cooling systems can accumulate deposits that promote corrosion.

In addition, some bacteria can grow in the cooling system water, especially if the water is stagnant. These bacteria produce organic acids that can corrode the steel. Regular cleaning and treatment of the cooling system can help prevent this corrosion.

Preventing and treating mold steel corrosion

Solving corrosion problems requires a combination of proactive strategies and reactive measures, depending on the type of corrosion. The following are the most effective solutions for preventing and managing mold steel corrosion:

Environmental control measures

During periods of inactivity, molds are susceptible to corrosion from exposure to moisture and environmental factors. Molds should be stored in a climate-controlled environment where temperature and humidity are controlled. To prevent corrosion during storage, rust prevention measures should be implemented:

- Control humidity: Strategic use of desiccants and dehumidifiers can effectively reduce ambient humidity, keeping the humidity in the storage area below 50% whenever possible.

- Temperature stability: Keep the temperature of the storage area stable to reduce the risk of condensation-induced corrosion.

- Rust prevention sprays or oils: These products form a protective layer on the mold surface, preventing moisture and oxygen from contacting the steel.

- Wax-based coatings: Wax-based coatings can provide additional protection for long-term storage. These coatings form a thick, durable film on the mold steel, making it very effective in preventing rust during long periods of inactivity.

- Seal the molds in airtight plastic packaging or containers: To further protect the molds, store them in airtight containers or plastic packaging to prevent exposure to moisture and environmental contaminants.

Use corrosion-resistant materials

- Stainless steel molds: Stainless steels with more than 12% chromium form an oxide layer that protects the metal from rust and corrosion.

- Hardened tool steels: Many tools contain additional elements such as molybdenum or vanadium to increase their corrosion resistance while maintaining the hardness required for molding applications.

Advanced surface treatments and coatings

- Nitrided coatings: By distributing nitrogen throughout the mold steel, the surface becomes harder and more resistant to corrosion and wear. Nitrided coatings can significantly reduce the risk of corrosion in high-temperature environments.

- Nickel and chrome plating: These are very effective in preventing rust and corrosion. They form a hard, smooth layer on the steel, protecting it from chemical reactions and oxidation.

- Corrosion inhibitors: Corrosion inhibitors can be applied as a spray or film and include specialized anti-corrosion paints, varnishes, and oils. These substances form a protective film on the mold surface that prevents corrosive substances from coming into direct contact with the steel.

Cathodic Protection

- Sacrificial anodes: Sacrificial anodes are placed near the mold, especially when dissimilar metals are present. These anodes absorb corrosion that would otherwise affect the mold steel.

- Anode wear monitoring: Ensure that sacrificial anodes are regularly inspected and replaced when necessary.

Mold design

Corrosion prevention training for employees

- Operational adjustments: Temperature-controlled injection molding cycles can help minimize thermal stress and condensation.

- Material training: The selection of processing materials should consider their potential to release corrosive byproducts. If possible, choosing non-corrosive alternatives or implementing proper ventilation and protection measures when working with potentially corrosive materials can significantly extend mold life.

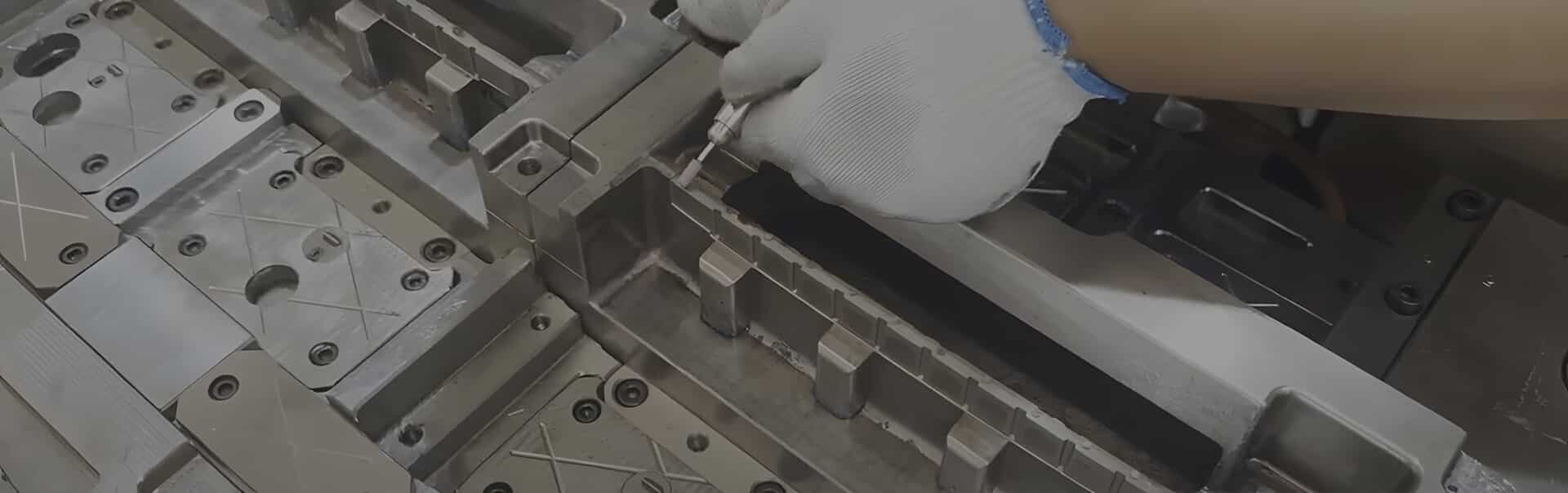

- Maintenance training: Train maintenance personnel on proper cleaning, drying, and preservation methods after each production run. Select cleaners that are compatible with mold steel and processing materials. Avoid using harsh chemicals, as they can damage the mold’s surface. After cleaning, ensure that the mold is completely dry to prevent water from being left on the surface or in crevices. Regular inspections for early signs of corrosion, pitting, or rust can help detect problems before they become serious.

Remedial measures

- Care is taken to properly clean and remove corrosion products through methods such as sandblasting, ultrasonic cleaning or chemical cleaning to avoid damaging the substrate.

- Damaged areas can be effectively repaired using surface repair techniques, including weld repair, precision polishing and re-coating.

- For stainless steel molds, repassivation helps restore the protective oxide layer, providing new corrosion resistance.

Conclusion

If not addressed promptly, mold steel corrosion can have serious economic and operational consequences. By understanding the root causes and implementing preventive or remedial measures, you can extend mold life, reduce downtime, and improve product quality.

Proactively managing mold corrosion is a long-term investment that pays off by reducing costly repairs, replacements, and production interruptions.

As a leading plastic mold manufacturer in China, YUCO MOLD has decades of expertise in avoiding mold corrosion. Our engineering team specializes in corrosion-resistant mold design and material selection, using the latest innovations in surface treatments and protective coatings.

In addition, we pride ourselves on our comprehensive approach to mold protection, from initial design consultation to ongoing maintenance support. Our commitment to quality is reflected in the long service life of our plastic molds.