mold steel for plastic mold

At YUCO, you can find more durable and affordable mold steels, and our goal is to remove the complexity and high costs of plastic molds for you.

choose right mold steel for YUCO project

The choice of mold steel can significantly affect the mold's durability, performance, and life. High-quality mold steel ensures that the mold can withstand the rigors of repeated use. For example, using the wrong mold steel for the injection mold can result in premature wear and tear and a fractured core or cavity. Besides, mold steel can significantly affect production quality by minimizing defects, reducing wear, and ensuring consistent output.

Now, YUCO will comprehensively introduce injection mold steel and see how we can choose the best mold steel according to your specific needs.

understanding your needs

Careful evaluation ensures that the steel selected will meet the needs of your project to optimize performance, life, and cost-effectiveness. Here are some things to consider:

1

molding method

Different molding methods have different requirements for mold steel. Injection molding requires steel that can withstand high-pressure and high-temperature cycles.

2

molding material

Different plastics have different wear resistance, corrosion, and thermal properties, affecting the mold steel's mechanical, chemical, and thermal properties.

3

design complexity

Simple designs may allow pre-hardened steel, which is easier to machine. Complex designs often require through-hardened steel to provide better performance in detail reproduction, dimensional stability, and wear resistance.

4

production volume

For small-volume production, pre-hardened steel can be selected, which is cost-effective. For large-volume production with millions of cycles, you need through-hardened steel or high-performance alloy steel to ensure extended mold life.

5

environmental factors

Consider the operating temperature and working conditions of the molding environment. For example, in environments where moisture or chemicals are present, corrosion-resistant steel may be required to prevent rust or wear.

6

maintenance and repair

While some steels have a long life with minimal wear, you should also consider steels that are easier to weld or repair, especially for large-volume and complex molds that may require regular maintenance.

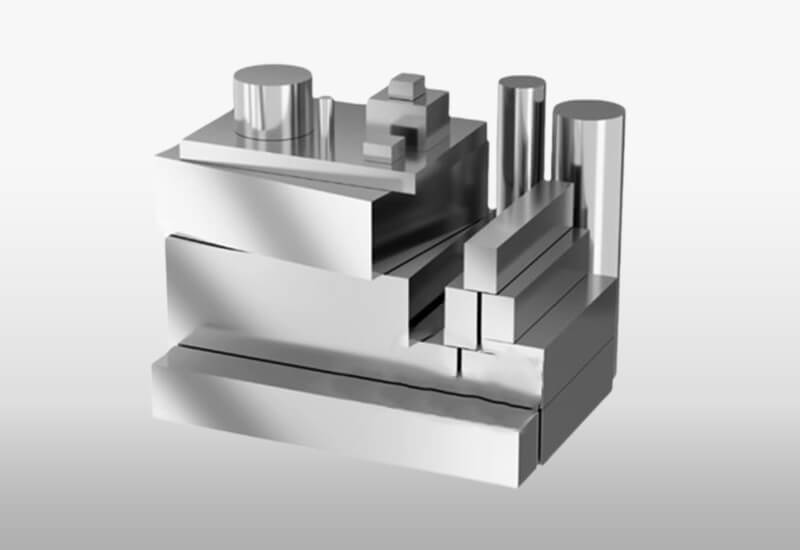

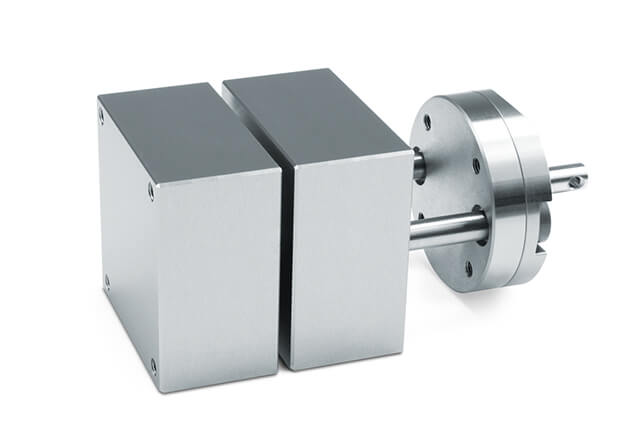

mold steel types

Mold steel needs excellent processing properties, such as minor heat treatment disorders, good corrosion resistance, polishing performance, etc. Below, YUCO introduces mold steel's main categories, each with its characteristics and typical applications.

Pre-hardened mold steels

P20 steel (1.2311)

In plastic injection molding, the most famous mold steel is P-20 steel. It is a pre-tough injection mold steel material, which means that when it leaves the factory, it is hardly strictly prepared for use in the mold. P-20 is commonly used in the manufacture of household items (bucket mold, basket mold, food container mold, etc.)

- Pre-hardened to 28-32 HRC

- The thermal stability of P20 is good.

- Easier to cut and form, reducing production time and costs.

- Suitable for medium-volume production.

- Medium corrosion resistance

S7 steel

S7 steel is a shock-resistant tool designed to withstand significant impact and vibration. It is often used in die-cast molds and other applications that require high stress and vibration resistance.

- There is tremendous resistance to trauma.

- It features clothing resistance.

- High hardness is a feature of S7 tool steel.

- It can resist scorching temperatures.

Through-hardened mold steels

H13 steel

H-13 is a multi-purpose material with abnormal stress properties, surface texture, friction resistance, and hardness. This is excellent for high-hat applications and deep cavity molds, as it is tricky for P-20 steel. In addition, it is ideal for high-temperature applications and usually works in large manufacturing quantities.

- H13 makes welding easier.

- It offers good resistance to rubbing.

- High hardness (up to 50-54 HRC)

- Able to withstand high-stress operation and thermal cycling.

- Good high-temperature strength

Corrosion-resistant mold steels

420 stainless steel

A corrosion-resistant and heat-driven type of stainless steel is called 420 steel. Due to its low cost and resistance to corrosion, it is often used by medical plastic injection molding producers and food-grade plastic injection molding producers.

- High hardenability (up to 50 HRC)

- Highly resistant to chemicals and moisture.

- Resistance to maintaining and wearing.

- Good machinability

S136 Stainless Steel

S136 stainless steel is often used to produce precision molds that require a high surface finish and resistance to corrosive environments. Commonly found in medical device manufacturing, optical components, and high-definition plastic products.

- Suitable for harsh environments exposed to moisture and certain chemicals.

- Provides a mirror finish, ideal for parts that require high aesthetics.

- Durable over long production runs.

High Performance Alloy Steel

Maraging steel

It is ideal for long-life molds with millions of cycles. Suitable for use in specialty applications such as aerospace components, high-performance tools, and complex injection molds that require high strength and precision.

- Ultra-high strength and toughness

- Minimal deformation during heat treatment

- Good machinability

Beryllium copper alloy

Suitable for complex mold inserts, cores, and high-performance applications that require rapid cooling, reducing cycle times and increasing production efficiency. For example, producing precision components in the electronics and telecommunications industries.

- Excellent thermal conductivity

- Durable and reusable.

- Non-magnetic and non-sparking

Immediately Start The Next Mold Project And Capture The Market

factors to consider when selecting mold steel

cost

Cost reservations when choosing mold steel include initial material costs, machining and fining costs, and long-term maintenance and alternative costs. A lower initial cost may be more attractive due to budget constraints, but cheaper steel may wear out faster and require more maintenance, ultimately resulting in higher long-term costs. Investing in high-quality mold steel can significantly extend the mold life service life, reducing required cycle frequency and maintenance costs.

Delivery time and purchasing

The lead time for a specific mold steel can impact project timelines. High-performance steel may take longer to purchase, impacting your production schedule.

When sourcing, make sure your mold steel supplier can reliably deliver steel that meets industry standards. Suppliers with relevant certifications (e.g., ISO, ASTM) typically demonstrate a commitment to quality and consistency.

thermal properties

- Cooling efficiency: High thermal conductivity allows for efficient heat dissipation, reducing cooling time and cycle times.

- Uniform cooling: Ensure the mold cools evenly to prevent warping or other heat-related defects in the final part.

- Dimensional stability: Low thermal expansion is essential for maintaining the dimensional stability of the mold as the temperature changes during the molding process. Molds that expand or contract significantly can result in inaccurate.

chemical properties

Because plastics contain chlorine, fluorine, and other elements, HCI, HF, and other attitudes will be exposed after heat and rotation after heat and rotation. This will attack the surface of the mold cavity. For molds exposed to corrosive materials, chemicals, or humid conditions, corrosion resistance is essential to prevent performance degradation and maintain performance over time. Steels such as stainless steel are often selected for their excellent resistance to harsh environments.

mechanical properties

Wear resistance

Wear resistance ensures that the mold maintains its shape and size in the event of frequent use, reducing the need for frequent replacement or repairs. Generally, the high hardness of dying with low loss means that wear resistance is good. At the same time, mold steel wear resistance is related to its type, quantity, and carbide shape.

Hardness

Stells are usually subjected to a certain amount of tightening to improve the mold’s capacity. Hardness is very important for mold steel performance as it determines the ability to absorb the energy of the material and resist cracking under stress. Mold work is very pressured and has a considerable impact burden. Hard steels are less likely to deform under pressure, maintaining the integrity of the mold and the quality of the plastic parts produced. Its hardness depends on carbon content and structure.

Toughness

Toughness is the ability of steel to absorb energy and resist breaking. This property is critical for molds that are subjected to high-stress operations or impacts, preventing cracking and extending the life of the mold.

Machinability

Steels with good machinability can be cut and shaped more easily, reducing manufacturing time and costs. Poor machinability can lead to increased tool wear and longer production times. In real work, the surface of the cores and the long-lasting, precise mold cavities can be nitrided to improve their resistance to clothing.

Weldability

Good weldability is essential for maintaining and repairing your molds. If your mold steel is easily weldable, the rebuild or repair process can be simplified, thus extending the life of the mold.

Surface finish

For the injection mold, the mold cavity surface directly affects the product’s surface. Well-polished steel is essential for molds that produce parts that require high aesthetics, such as clear plastics or parts with intricate details.

FAQs for mold steel

How does plastic mold type affect the selection of steel?

Plastic-type molding has a significant impact on the choice of steel. For example, rough materials such as glass-filled plastic require high wear resistance steel, such as D2 or M2 tool steel. Corrosion-resistant steel like PVC -like corrosion plastics, 420 stainless steel. Soft plastic can be shielded with low wear-resistant steel like P20. In addition, if plastics have a high thermal conductivity, choosing a steel that can handle the cooling fast is necessary to prevent defects and ensure effective production.

What are the benefits of pre-hard mold steel?

Pre-hard mold steel offers many benefits. It provides:

- Quick use of suitable hardness. Eliminating the need for heat treatment.

- Saving time and costs. These steels balance machining and stability, making them ideal for low—to medium-sized production.

- Pre-tough steels also reduce the risk of warping or dimensional changes during heat treatment, ensuring high accuracy and consistency in the final mold.

How does the mold's complexity affect the steel choice?

The complexity of the mold plays a vital role in the selection of steel. Excellent molds and excellent features with complex molds benefit from excellent machining and polishing, such as P20 or 420 stainless steel with steel. These features ensure the mold can be precisely shaped and eliminated to achieve the desired detail and surface standard. In addition, complex molds often require strict steel to cope with pressure and potential effects during molding.

How does heat treatment affect the mold steel properties?

Heat treatment can significantly increase the properties of mold steel by increasing hardness, wear resistance, and stiffness. Steel’s microstructure is strict and temperamental to achieve the desired mechanical properties. For example, H13 steel is often treated in heat to increase its stiffness and thermal fatigue resistance, which is suitable for high-temperature applications. Proper heat treatment can increase the life of the mold and improve its performance, but it requires precise control to avoid problems such as warping or cracking.

YUCO MOLD - mold steel expert

When you choose the correct tool steel for your plastic injection molding project, you can make an informed choice by familiarizing yourself with the specific features of all types of injection mold steel. To help you choose the best option for your product, you should speak with YUCO expert.

- Strength factory with many fine equipments strength factory with many fine equipments

- Customized mold design

- Perfect quality management system

- Senior engineers with more than 10 years experience

- One-stop service from design to molding

Tel: +86 13586040750