mold manufacturing service

As a leader in China's injection mold industry, YUCO focus on providing you with high-quality custom mold manufacturing services to meet your unique needs.

injection mold manufacturing services

YUCO provides you with best-in-class injection mold manufacturing service. At every stage of mold manufacturing, our experts ensures precision and quality to provide you with the best results.

- Customized services: Every aspect of the mold manufacturing process is customized for you.

- Mold flow analysis: Predict and optimize the manufacturing process, reducing the risk of defects.

- One-stop service: We provide a one-stop service from design to manufacturing.

- Mold tracking services: We continuously monitor and report on mold performance.

- Single cavity molds, multi cavity molds, family molds.

Competitive pricing

Advanced CNC machines

10+ years of experience

Customizable mold solutions

Meeting diverse mold solutions

We focus on producing a variety of molds to meet diverse injection mold solutions. Whether you are looking for efficiency, precision or innovative mold solutions, we provide you with technical solutions and insights.

collapsible core molds

Our collapsible core molds are specifically designed to produce complex components with internal features that are not possible with standard core pulls.

hot runner molds

Our hot runner molds utilize heated components to maintain the melt flow of plastic within the mold, reducing waste and shortening cycle times.

Cold Runner Molds

Our cold runner molds are a cost-effective alternative to hot runner systems, with a system of channels that cool and solidify the molten plastic before it reaches the mold cavity during each cycle.

Contact our mold manufacturing experts now!

mold manufacturing process

The mold manufacturing process is a meticulous and technical process. Here are the detailed steps involved in making a high-quality injection mold, from initial design to final testing.

1

Mold design

During this phase, our engineers utilize advanced CAD systems to determine the mold geometry, gate locations, runner systems, and part ejection mechanisms to meet the specific requirements of the final product.

2

Selection of mold materials

Choosing right mold material is critical for functionality and longevity. This typically includes various grades of mold steel, each with different advantages in terms of durability, cooling performance, and cost-effectiveness.

3

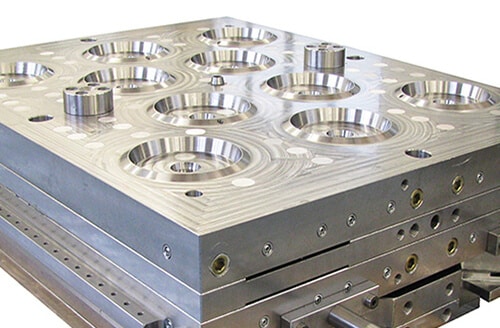

Mold processing

The individual components of the mold are manufactured with high precision using technologies such as CNC machining, EDM, and precision grinding. Ensure that the mold meets the tolerances required for optimal performance.

4

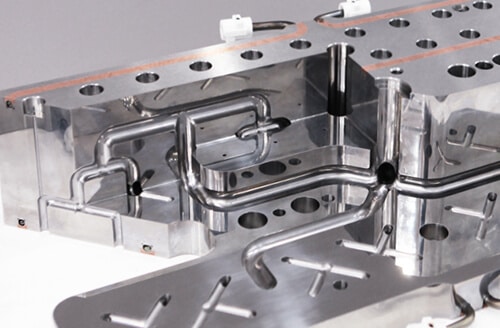

Adding cooling channels

Cooling channels help regulate the temperature of the mold during the injection process. The correct placement and sizing of cooling channels can significantly reduce cycle time and prevent defects in the final product.

5

Mold finishing and assembly

The finishing process includes polishing and texturing to achieve the surface finish required for the final product. The components must be strong and durable to withstand repeated cycles of injection molding under high pressure conditions.

6

Testing and adjustment

Mold testing is the rigorous testing of the mold under actual operating conditions to ensure it performs as expected. Adjustments are made to fine-tune the mold for optimal performance, and extensive trials are conducted to verify that the mold is ready for full production.

Mold Machining core equipments

YUCO's advanced mold machining tools and equipment ensure that each mold is strong, precise, and capable of supporting high-volume manufacturing processes.

Double head EDM machine

High speed milling

5-Axis Machining Centres

Driller

Boring machine

CNC machine

Coordinate measuring machine

Mold inspection

FAQs for mold manufacturing

Here you can find answers to common questions about the mold manufacturing process, helping you navigate the complexities of mold manufacturing and ensuring the best results for your specific needs and projects.

What is mold manufacturing?

Mold manufacturing is the process of designing and constructing a tool that can be used to replicate a part or object through injection molding, casting, or other molding methods.

How long does it take to make a mold?

Depending on the complexity of the object being molded, the time required to design and build a mold can vary greatly, from a few days to a few weeks.

Can molds be reused?

Yes, molds are designed to be reused, and durability depends on the material and process. Metal molds can generally produce more parts before they wear out than silicone or plastic molds.

What are the tolerances for mold manufacturing ?

Tolerances vary, but are generally tight to ensure that parts meet strict dimensional accuracy. Exact tolerances are critical to the assembly of the final product.

How are molds maintained?

Regular maintenance includes cleaning after each use, ensuring that surfaces are free of residue, checking for wear or damage, and lubricating moving parts when necessary.

How much does it cost to make a mold?

Costs vary depending on the complexity and size of the mold, ranging from a few hundred dollars for a simple project to thousands of dollars or more for an industrial-scale mold.

YUCO MOLD - mold manufacturing expert

Are you struggling with complex mold designs, tight tolerances, or tight production schedules? YUCO MOLD can turn your manufacturing challenges into opportunities for innovation and growth.

- Innovative mold design and engineering

- Rapid prototyping and production

- Unmatched precision and quality

- Industry-leading turnaround times

- Expert consulting tailored to your needs

Whether you’re in automotive, medical, consumer goods, or any industry that requires high-performance molds, YUCO MOLD has the expertise to advance your production capabilities. Contact us today to learn how we can revolutionize your mold manufacturing.

Tel: +86 13586040750