molding solutions

YUCO is committed to providing you with comprehensive solutions for injection molding. We are a leader in providing high-precision, tailor-made molding solutions.

Solutions for injection molding

To meet a wide range of production needs, we focus on providing tailored solutions for all scales and stages of product development, from initial concept to high-volume production.

Low volume injection molding

Today, low-volume injection molding has become a critical manufacturing process in market. As consumer demand shifts toward more personalized and customizable products, you need to be able to produce small batches of customized products without incurring prohibitive costs.

High volume injection molding

YUCO excels in every aspect of high volume injection molding. Our commitment to quality, advanced technology and customer focus ensures exceptional results.

Prototype injection molding

YUCO is a full-service manufacturer with over 10 years of prototype injection molding experience, producing high-quality prototypes in no time using our proven manufacturing processes.

Custom Injection Molding

Custom injection molding is at the core of our professional services. Through a highly collaborative approach, we develop custom molds and select specific materials to meet your unique needs.

Injection molding process

We focus on the entire injection molding process, from initial design to the final production of molded plastic parts. Each stage is customizable for you.

01

Customization

02

Mold design

03

Mold manufacturing

04

Mold testing

05

Plastic molding

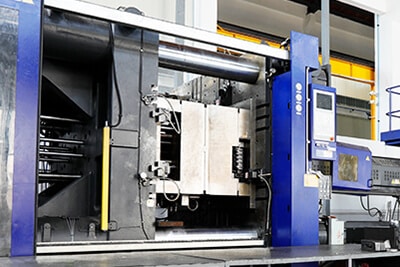

Injection molding's core equipments

YUCO MOLD has a wide range of advanced molding equipment, providing the best technology and performance for your tailor-made molding solutions.

High-speed EDM

High speed milling

Driller

Coordinate measuring machine

Boring machine

Drilled hole

CNC machine

Injection molding machine

Mold manufacturing capabilities

We have excellent mold manufacturing capabilities. The most advanced equipment and innovative technology to produce high-quality molds ensure the best performance and durability of our molds.

| Equipment | Details | Techniques | Tolerances / Certifications |

| CNC Milling | 3-axis, 4-axis, 5-axis CNC Milling | CNC milling of metals and plastics | Precision of ±0.005 mm |

| CNC Turning | Threading, boring, drilling and knurling | Form turning, chamfering and cutting | ISO 2768 CNC machining standard |

| EDM | Approved by over 52 mold and die makers | Sink EDM\Wire Cutting\Small hole EDM | ±0.005 mm |

| Precision Grinding | Centreless grinding | External cylindrical grinding (OD and ID) \ Surface grinding |

±0.003 mm |

| Coordinate measuring machine | Detection of discrete points on the mold surface | Strict quality assurance and quality control | ±0.003 mm |

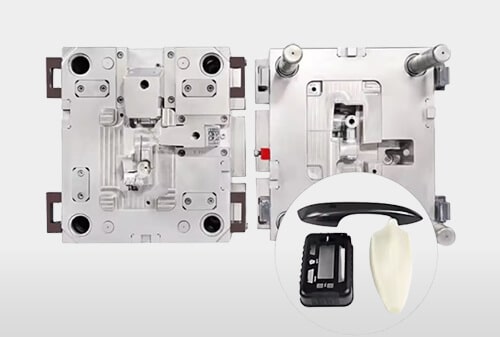

Mold case

We handle various complex needs of our customers with precision and professionalism. Below are some of our classic cases.

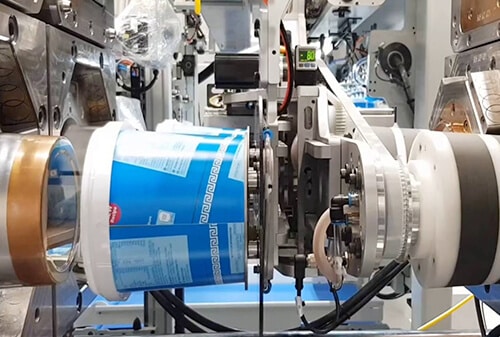

IML Bucket Mold Success Case in Spain

- IML injection molding

- bucket mold making

- Plastic bucket design

This project involved the design and manufacture of high-precision molds for plastic barrels to meet the strong demand of the Spanish market. The customer benefited from an optimized production process, resulting in cost savings and reduced turnaround time.

Mexico 5 gallon cap Mold Case

- 5 gallon cap solution

- 5 gallon cap mold making

- 5 gallon cap design

The preforms for this project required high definition and precise dimensions to ensure compatibility with a variety of 5 gallon cap designs and capping machinery. The final mold produced 5 gallon caps that met all qualitative and quantitative benchmarks, improving the customer's production capacity and quality control.

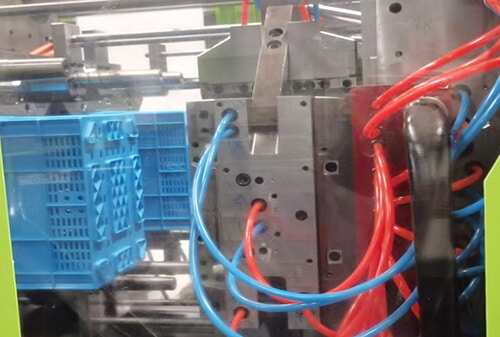

Crate Molding Case in Turkey

- crate molding solution

- crate mold making

- plastic crate design

The crates produced by the molds successfully designed by YUCO not only met but also exceeded expectations in terms of durability and cost-effectiveness.

Russian Trash Bin Mold Case

- Trash bin solution

- Trash bin mold making

- Trash bin design

YUCO developed a highly specialized two-part mold using high-quality steel, including an advanced air injection system to speed up the production process.

YUCO MOLD - mold steel expert

When you choose the correct tool steel for your plastic injection molding project, you can make an informed choice by familiarizing yourself with the specific features of all types of injection mold steel. To help you choose the best option for your product, you should speak with YUCO expert.

- Strength factory with many fine equipments strength factory with many fine equipments

- Customized mold design

- Perfect quality management system

- Senior engineers with more than 10 years experience

- One-stop service from design to molding

Tel: +86 13586040750