high-volume injection molding

YUCO excels in every aspect of high volume injection molding. Our commitment to quality, advanced technology and customer focus ensures exceptional results.

Understanding high-volume injection molding

high-volume injection molding, also known as mass injection molding, is a manufacturing process used to produce large quantities of plastic parts in a short amount of time. The method is designed to produce thousands to millions of parts and focuses on maximizing efficiency and consistency.

High-volume injection molding is a sophisticated manufacturing process at the heart of modern industrial production. Its technique allows for the rapid and efficient manufacturing of large quantities of plastic parts, making it a cornerstone of various industries, including automotive, electronics, consumer goods, and more.

Advantages of high-volume injection molding

High-volume injection molding offers several advantages, including high production efficiency, rapid production of large parts, consistent part quality and dimensional accuracy, etc. It is cost-effective for mass production and enables the production of complex geometries with minimal post-processing.

High productivity and efficiency

High-volume injection molding is designed to increase efficiency. Every second counts from the moment the raw material enters the injection molding machine to the final exit of the finished part. YUCO invests in advanced technology, fine-tune process parameters, and optimize mold design to squeeze every ounce of efficiency out of the production line. This high throughput is ideal for industries that require large quantities of consistently high-quality parts.

Low unit costs despite high initial setup costs

While the initial investment in mold design and manufacturing can be large, unit costs decrease significantly as production volumes increase. This is due to the economies of scale that high-volume injection molding offers. By spreading the initial costs over a large number of units, we can offer extremely competitive pricing for volume orders.

Consistent product quality

But performance alone is not enough. In the world of high-volume injection molding, quality cannot be compromised. Achieving this level of quality requires a meticulous approach, from selecting the right materials to implementing rigorous testing and inspection.

Contact YUCO molding experts now!

critical considerations for high volume injection molding

To achieve the best results in high-volume injection molding, several key factors must be considered. Below, we will explore these considerations in detail and highlight why you should choose YUCO's high-volume injection molding services.

material selection

The quality of molded parts is directly impacted by the quality of the raw materials. Choosing the right materials is critical to ensuring product performance, durability, and cost-effectiveness. Thermoplastics are the most widely used materials in high-volume injection molding because of their versatility, durability, and ease of processing.

Criteria for selecting suitable materials:

- Strength: Materials need to withstand mechanical stress without deforming.

- Flexibility: Depending on the application, the material should be appropriately flexible or rigid.

- Heat resistance: Important for parts exposed to high temperatures.

- Chemical resistance: Essential for parts that meet chemicals.

- Cost-Effectiveness: Balancing material performance with price considerations.

Material examples

Common materials

- Polypropylene (PP): Widely used due to its balance of strength and flexibility.

- Polyethylene (PE): Known for its chemical resistance and versatility.

- Acrylonitrile Butadiene Styrene (ABS): Popular for its strength and durability.

Advanced materials

- High-performance polymers: such as PEEK or PPS, provide excellent mechanical and thermal properties.

- Functional additives, such as conductive fillers, flame retardants, or antimicrobial agents, are added to impart specific properties to molded parts.

- We are investigating using bioplastics, recycled plastics, and bio-based polymers to reduce environmental impact and meet sustainability goals.

At YUCO, we can guide you through material selection, ensuring the selection meets your specific needs and production requirements. In addition, YUCO has a material management system and implements strict acceptance standards to always purchase materials from reputable and stable suppliers. Finished materials are tested to verify strength, viscosity and thermal stability. Our rich experience in material handling minimizes waste, reduces downtime and improves material utilization.

mold design

Mold design is fundamental to the success of high-volume injection molding. A strong mold ensures consistent quality, reduces cycle times, and minimizes defects.

We use the latest CAD software for precise design and topology optimization algorithms to minimize material usage while maintaining structural integrity and functionality.

In addition, we work with customers to develop innovative solutions to meet requirements such as lightweighting, functional integration, or assembly consolidation.

To meet mold manufacturability requirements (simplifying production and reducing the need for rework or modifications), we can design molds with multiple cavities, hot runners, and efficient cooling channels, including:

- Two-plate molds: simple design, ideal for less complex parts.

- Three-plate molds: allow for more complex geometries and improved gate positioning.

- Hot runner systems: improve efficiency by reducing waste and shortening cycle times.

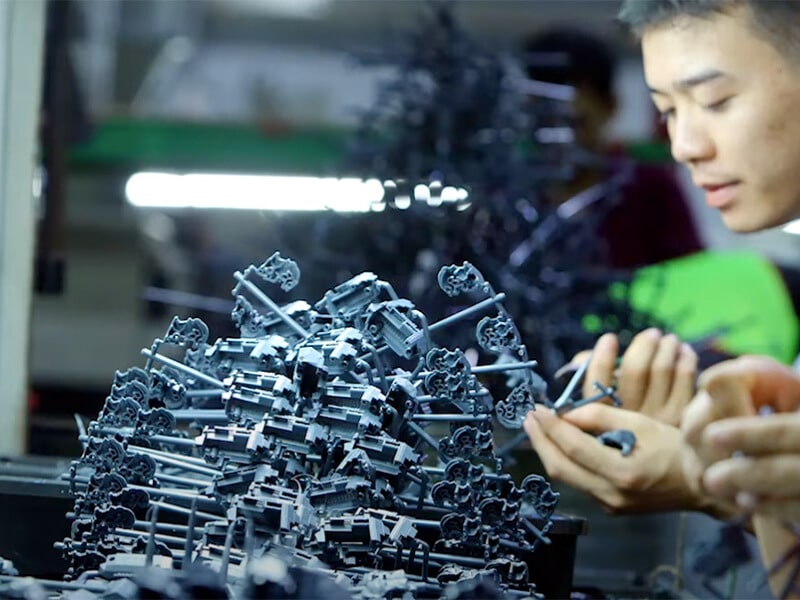

mold manufacturing

Mold is a precision-engineered tool that defines the shape and properties of the final part. Its two constituent parts are the cavity and the core, which are connected to create the required shape.

Choosing high-quality tooling materials can improve durability and longevity, reducing downtime for maintenance or repair. YUCO considers the expected production volume and selects materials that will ensure the mold will last throughout the production cycle with minimal maintenance.

Material used for molds

- Steel: High-strength mold steels such as P20 or H13 ensure long life and can handle high-volume production.

- Aluminum: It can be used for prototypes and short-run molds as it is easy to process and cost-effective.

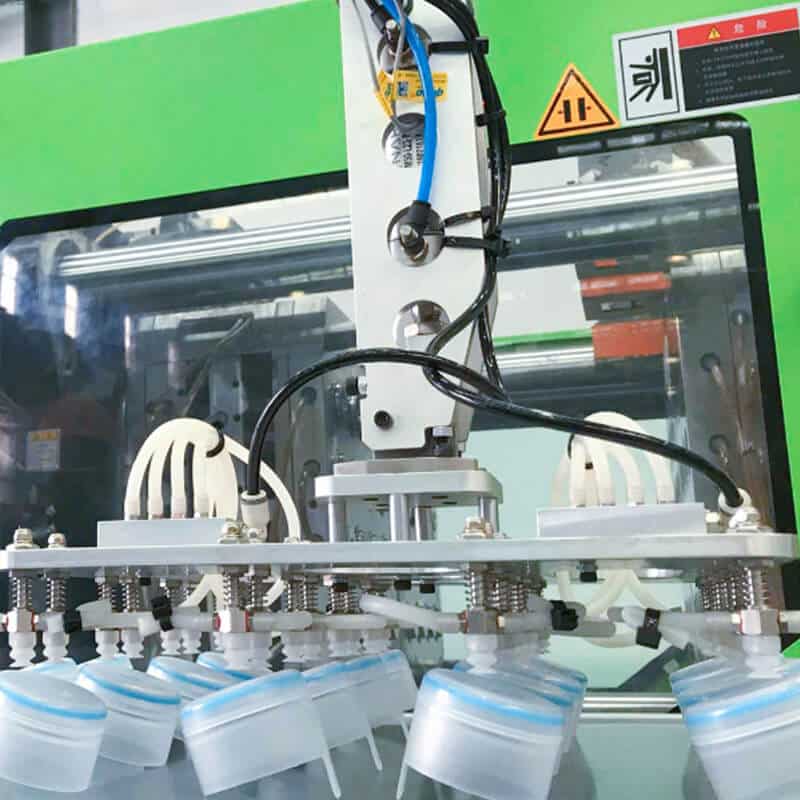

injection molding machine

The injection molding machine, which is the center of the operation, is made up of a hopper for feeding raw materials, a heating barrel for melting them, and a screw or plunger mechanism for forcing the melted materials into the mold cavity. Investing in the latest injection molding machines with advanced features can significantly increase efficiency. At YUCO, we have a wide range of injection molding machines designed to meet a variety of production needs.

- Matching machine capacity to production needs

- Clamping force are select based on part size and complexity.

- Advanced control systems ensure precise regulation of process parameters such as temperature, pressure, and injection speed, ensuring great part quality.

- All critical parameters are carefully set and calibrated to maintain consistency.

- Energy-efficient machines help reduce operational costs and environmental impact by minimizing power consumption during production.

- Faster machines can reduce cycle times, producing more parts in a shorter period.

Production process optimization

From raw materials to finished products. Our comprehensive production process includes material preparation, mold loading, injection, cooling, and ejection.

Initially, we used simulation software to optimize parameters such as temperature, pressure, and cooling time to ensure efficient and high-quality production.

Implement IoT (Internet of Things) sensors and connectivity to collect and analyze data from injection molding machines, molds, and auxiliary equipment. During production, we monitor important process parameters in real time, including temperature, pressure, injection speed and cooling time, and perform data analysis. The control system will automatically adjust process parameters based on feedback from sensors and monitoring equipment to maintain part specifications and quality.

Predictive maintenance

We use predictive maintenance techniques to anticipate and prevent equipment failure, minimizing downtime and maximizing uptime.

We establish a comprehensive mold maintenance schedule, including cleaning, lubrication, and inspection for wear and tear. to identify any signs of damage, corrosion, or deterioration that could affect part quality.

Conduct regular process audits to identify deviations from optimal conditions and take corrective actions as needed.

In-process inspection and testing at various production stages help identify defects early and prevent the production of non-conforming parts.

We cultivate a culture of quality among employees and encourage participation in problem solving and problem prevention.

Final inspection and quality assurance

Before parts are released for shipment, they undergo a final inspection and quality assurance check to ensure they meet all specified requirements. This includes:

Comprehensive dimensional inspection using coordinate measuring machines (CMMs) or other precision measuring tools.

Functional testing under simulated operating conditions to verify performance and reliability.

Documentation of inspection results and verification of compliance with customer specifications and industry standards.

Advanced technologies:

Harnessing the power of Industry 4.0 technologies enables the development of intelligent injection molding systems capable of self-optimization, predictive maintenance, and real-time quality control.

Various auxiliary equipment, such as cooling systems, robots, and automation, are essential in optimizing injection molding. Cooling systems help rapidly solidify molten materials, while robots and automation facilitate mass production with precision and efficiency, reducing labor costs and increasing throughput.

- Gas-assisted injection molding: Provides advantages like reduced material usage and improved part strength, ideal for hollow or thick-walled components.

- Multi-color injection molding: Enables production of multi-material or multi-color parts in a single operation.

- In-mold labeling and decoration: Enhances the aesthetic and functional properties of the parts, integrating labels and decorations into the molding process.

Sustainable practices

We are adopting a recycling system to recover and reuse scrap materials generated during injection molding, reducing waste and promoting circular economy principles.

We are designing products for disassembly, reuse, and end-of-life recovery, considering material selection, design for recycling guidelines, and environmentally friendly manufacturing processes.

applications of high-volume injection molding

High-volume injection molding is a versatile manufacturing process that can be used in a wide range of industries. It can produce large quantities of high-quality, consistent parts and is indispensable in the automotive, medical, consumer goods, packaging, and other fields. Below are specific examples of YUCO's own production projects.

smart home device housings

We produced smart home device housings for a technology company. The use of a PC/ABS blend provided the necessary strength, heat resistance, and smooth surface. Our capabilities in multi-color injection molding and in-mold decoration enable these devices to meet stringent design standards, integrating functionality with high-end consumer aesthetics.

Custom reusable water bottles

We work with leading consumer brands to produce custom-designed reusable water bottles. Our injection molding process allows for complex design and personalization options, resulting in highly attractive and functional products. Using BPA-free polypropylene, we ensure safety and durability, meeting consumer demand for eco-friendly and fashionable hydration solutions.

Innovative cookware sets

FAQs about high-volume injection molding

What are some common challenges in high-volume injection molding?

Common challenges in high-volume injection molding include managing tooling costs, minimizing production waste, maintaining consistent part quality, overcoming design limitations, and remaining competitive in a rapidly evolving market.

What is the typical lead time for high-volume injection molding projects?

Lead times for high-volume injection molding projects can vary based on part complexity, mold design, material availability, and production volume. Larger or more complex projects usually require longer lead times, typically from a few weeks to several months.

YUCO MOLD - Start high volume molding

At YUCO, we are committed to providing you with unparalleled value with our high-volume injection molding services. Whether you require a complex, intricate design, or large quantities of identical parts, we have the capabilities to meet your needs efficiently and cost-effectively. Contact us today to learn more about how we can support your manufacturing goals.

- With years of experience in the industry, our team has the knowledge and skills to handle the most demanding projects.

- Our state-of-the-art manufacturing facilities are equipped with the latest technology, allowing us to deliver high-quality products with exceptional efficiency.

- We work closely with our customers to understand needs and provide custom solutions that meet their specific requirements.

- Quality is at the heart of everything we do. Our rigorous quality control process ensures that every part we produce meets the highest standards of excellence.

- We can provide cost-effective solutions without compromising on quality.

Tel: +86 13586040750