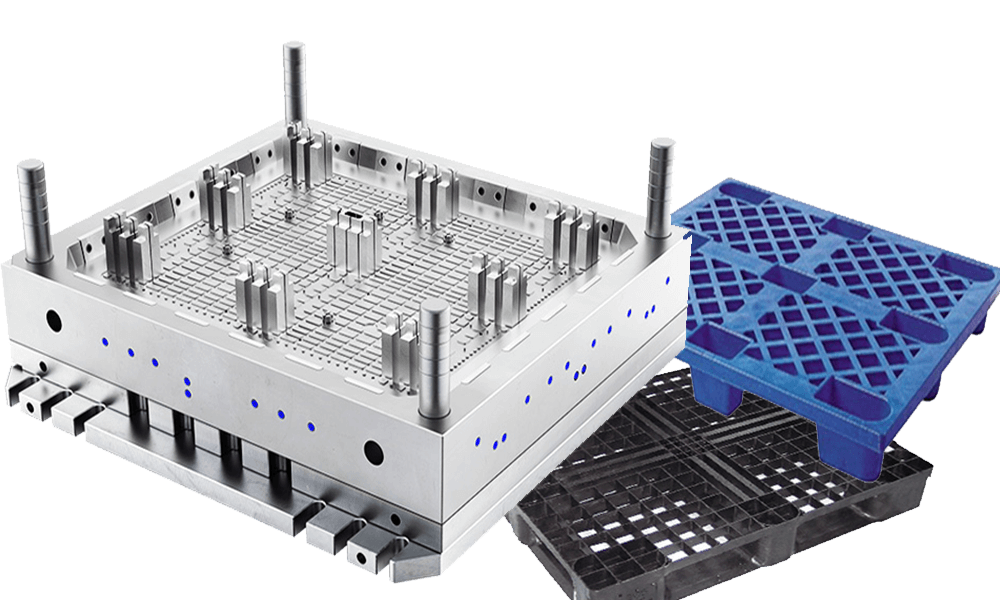

plastic pallet mold design & manufacturing in China

Revolutionize your business with our custom plastic pallet solutions — Expert design, high-precision mold manufacture and high-volume pallet molding.

The difference of YUCO MOLD plastic pallet mold solutions:

Pallet molds are made in China, and YUCO has in-house capabilities covering the entire mold production process, from design, processing, sampling to mass production. This ensures excellent delivery time, total cost control and consistent product performance.

- Top materials: We use only the best materials and innovative processing techniques to ensure the longevity of our molds and employ replaceable components in high-wear areas. This results in minimal deformation and high precision after long-term mold operation.

- Fast and efficient: Our experienced mold designers will perform detailed DFM design, adopt the best injection molding system, proper gate design, efficient cooling system and easy demoulding mechanism to ensure a fast and efficient production cycle.

- Durable: Our pallet design capabilities are incredible. These pallets are strong and durable, and have passed rigorous drop tests, load tests and chemical resistance tests, meeting all industrial pallet standard requirements.

- Sustainability: YUCO's pallet molds are designed with a special built-in filtration system that allows us to use recycled plastic waste instead of new materials.

plastic pallet mold capabilities

As a leading plastic pallet mold manufacturer in China, we manufacture high quality and consistent pallet molds and pallets for many customers from different countries. Compared with traditional wooden or metal pallets, plastic pallets have been widely used due to their advantages such as light weight, durability, hygiene, and cost-effectiveness. YUCO offers a wide range of capabilities to meet different customer needs:

Pallet sizes

400 x 300 mm

600 x 400 mm

800 x 600 mm

1200 x 800 mm

1200 x 1000 mm

1200 x 1200 mm

Up to 1500 x 1500 mm

pallet materials

High density polyethylene (HDPE)

Polypropylene (PP)

PVC

Recycled plastic

Pallet types

Nestable pallets

Stackable pallets

Hygienic pallets

Export pallets

Single-sided plastic pallets

Double-sided plastic pallets

Two-way pallets

Four-way pallets

load capacities

Light duty: up to 500 kg

Medium duty: 500-1000 kg

Heavy duty: over 1000 kg, up to 2500 kg for special applications

| Mold attributes | Parameter |

| Mold Material | P20 / 718 / 2738 / H13 / S136 / NAK80 etc |

| Mold cavity | Single cavity |

| Ejection System | Ejector pin or ejecting block or depends on the part construction |

| Mold runner | Cold runner/hot runner |

| Material Handling | Quenching / Nitrided / Heat |

| Mold surface | Texture / Mirror polish |

| Mold Base | DME / LKM / HASCO / LOCAL |

| Mold life | 500, 000~ 1 million shots |

| Customizable | Yes |

| Product Material | PP / PE |

| Our Services | Mold design / Mold manufacturing / Plastic injection molding / OEM service |

| Delivery time | 50-60 days |

| Mold standard | Domestic standard LKM, HASCO standard, DME standard |

Brighten up your next plastic pallet mold!

We do both pallet mold production and mass production of various plastic pallets. Welcome to customize your own molds and products.

Plastic pallet mold manufacturing process

YUCO MOLD uses a rigorous and complex process to manufacture high-quality plastic pallet molds. The process can be divided into three key stages:

Mold steel selection

The foundation of a high-quality plastic pallet mold lies in the careful selection of mold steel. We consider several factors when choosing the right steel for each project, including durability, thermal properties, machinability, polishability, and hardness.

We use high-grade tool steels such as H13, P20, and S7, which are known for their excellent wear resistance and ability to withstand the high pressure and temperature of the injection molding process.

In addition, we verify the correctness of the ordered steel before manufacturing to ensure that the selected steel meets the standards for manufacturing high-quality pallet molds.

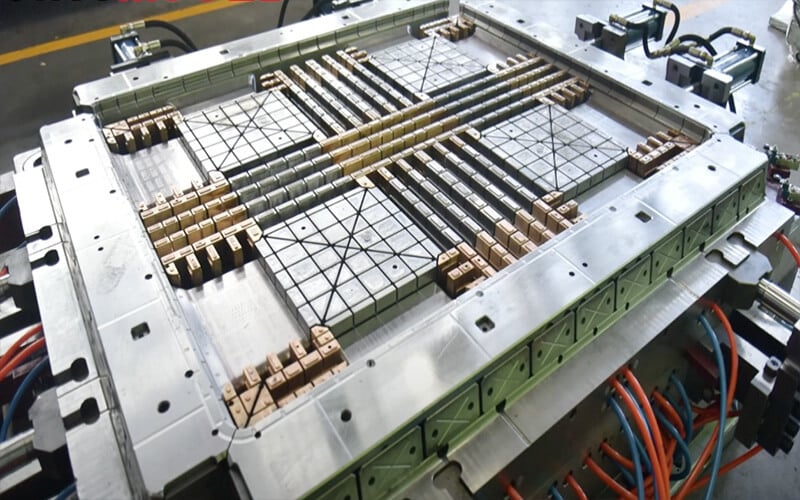

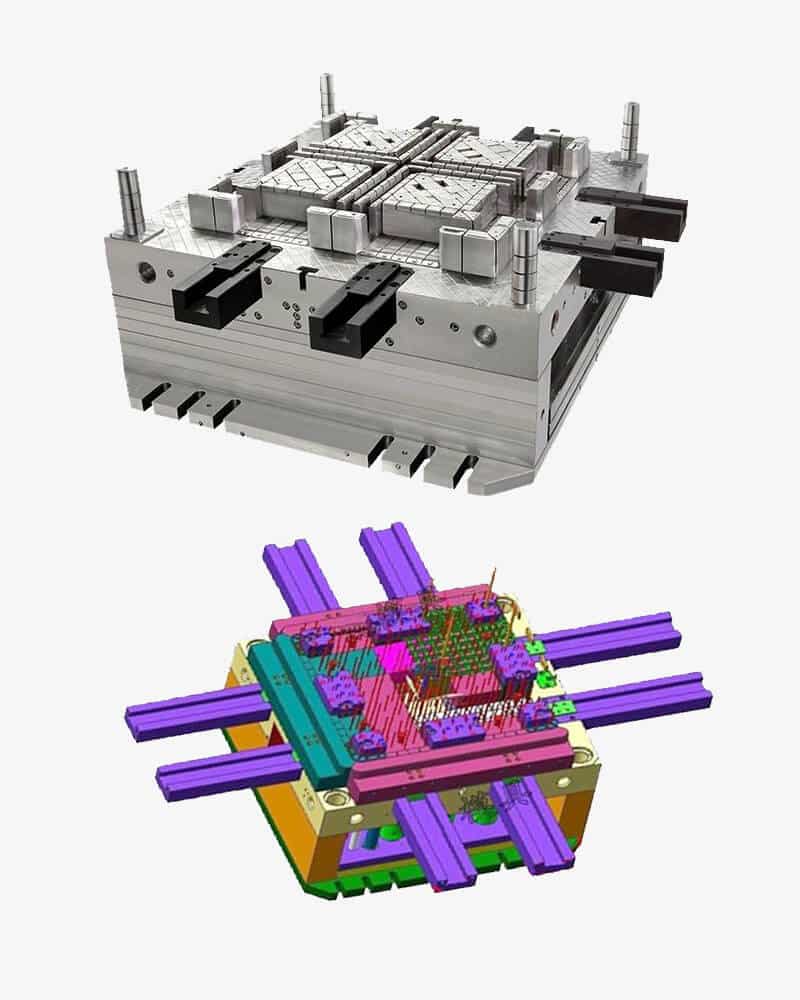

Processing technology

YUCO uses 5-axis CNC milling, EDM and other machining technologies to precisely cut and shape mold components. This technology enables us to create complex geometries and ensure tight tolerances.

Since the pallet mold is large, if it is produced as a whole, the production cycle is long and the requirements for processing equipment are high. YUCO adopts assembly production, that is, multiple small machines are processed at the same time, which can shorten the production cycle by half.

Finally, we use various surface treatment techniques to achieve the desired texture and appearance, such as

- Polishing: for smooth, shiny surfaces

- Texturing: for non-slip or branded surfaces

- Coating: for enhanced wear resistance and reduced friction

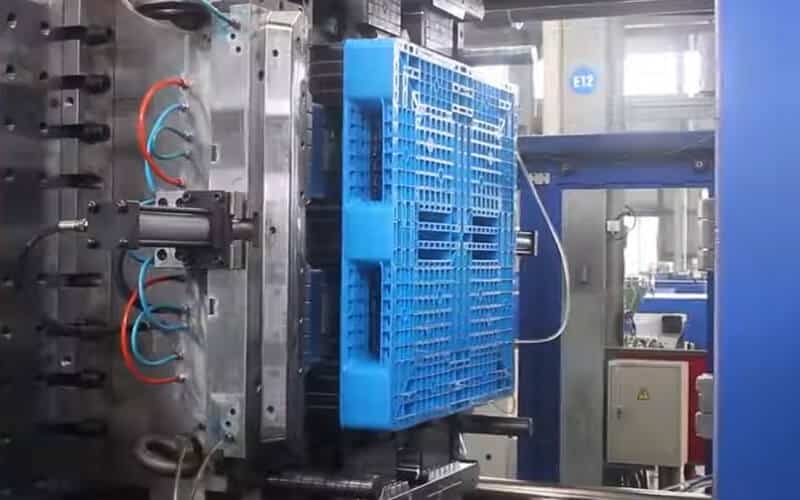

Quality control and testing

The final stage of our manufacturing process involves rigorous quality control and testing procedures. Based on the results of the tests, we continuously make any necessary adjustments to optimize the performance of the mold, such as cycle time, cooling efficiency, and part release.

First, we carefully assemble all mold components to ensure proper fit and alignment. Then we conduct an initial test run to produce a sample tray. Next, we will conduct a coordinate measuring machine (CMM), surface finish inspection, ultrasonic testing, etc. to ensure that it meets all requirements before leaving our factory floor.

How to design a plastic pallet mold?

Designing a plastic pallet mold is a complex process that requires careful consideration of multiple factors. We divide it into three main parts - product design, mold design, and injection molding design.

product design

Before designing the mold itself, we must first optimize the design of the plastic pallet. Key considerations include:

- Load capacity: We calculate the required load capacity based on the intended use of the pallet. This affects the overall structural and reinforcement design of the pallet.

- Pallet size: We determine the optimal size to meet industry standards and customer requirements.

- Pallet shape: Is it stackable, rackable, or nestable? We can help you design any type of pallet you need, from lightweight pallets to giant Euro pallets.

- Ribs: We add structural ribs to enhance strength while minimizing material usage.

- Pallet weight: Our goal is to achieve the lightest possible weight without compromising strength. We optimize part wall thickness and material usage and use structural foam molding where appropriate to achieve the necessary strength without unnecessary weight.

- Material selection: We select the right plastic based on strength requirements, cost, and recyclability.

- Special features: We add functional features such as non-slip surfaces, flame retardant, and disinfection as needed.

Mold runner design

Unbalanced runner configuration often leads to overfilling in the section closest to the gate, while the section at the end of the feed system may also be underfilled. We optimize the runner system to ensure balanced filling of all cavities. In addition, all runner branch connections or intersections should be as curved and blended with radii as possible to minimize the pressure drop caused by the molten polymer flowing through the system. According to the characteristics of the tray, YUCO will use its expertise to help select cold runner, cutting-edge hot runner, or valve hot runner system.

Mold gate design

Plastic pallets are large and heavy products that can cause problems when filling. CAE must analyze multi-point gates to avoid any defects on this important part of our design, which will affect the strength of the pallet. We carefully select the gate location and type (e.g. edge gate, submerged gate) to minimize visible gate marks and ensure proper filling. YUCO’s proprietary gating technology enables our customers to produce plastic pallets using resins with melt flow rates as low as 1.

Mold ejector design

Due to the product structure, pallet molds often require a large number of ejector pins for ejection. We strategically place ejectors where the product structure is well supported and select high-quality pin accessories so that the pallet receives uniform force and reduces any deformation. For complex designs, we may use pneumatic or hydraulic ejector systems.

Mold cooling design

Use CAD software for detailed and accurate cooling design. Use efficient cooling channel layout to ensure uniform cooling, avoid hot spots and minimize cycle time. For complex tray designs, we consider using conformal cooling technology. We have helped customers optimize cooling design and significantly reduce the overall cycle time by 30%.

Optimizing the injection molding process

Our design process is iterative, with continuous feedback between the product, mold, and process design stages. Through simulation and testing, we adjust mold and process parameters to prevent common defects such as warpage, sink marks, and short shots. We also adjust injection speed, pressure, and cooling time to achieve the shortest cycle time without compromising quality. This allows us to improve and optimize the entire system, ultimately meeting or exceeding our customers’ expectations for performance, durability, and cost-effectiveness.

Plastic pallet injection molding process

In the field of plastic pallet manufacturing, two main injection systems play a vital role. YUCO has advanced injection systems that can reduce the molding cycle of plastic pallets and can handle orders from one prototype design to mass production of millions of pieces

- Low-pressure structural foam molding involves injecting a mixture of plastic material and inert gas into the mold cavity. You can use carbon dioxide or nitrogen. After heating, it can produce a honeycomb core surrounded by hard plastic material. This method has proven to be ideal for making plastic pallets with the best strength-to-weight ratio, ensuring durability and cost-effective production. The plastic pallets produced in this way have a higher strength-to-weight ratio, consume less material, and have low production costs while still maintaining durability.

- High-pressure injection molding are widely used in the manufacturing of high-density polyethylene (HDPE) or polypropylene (PP) plastic pallets to produce plastic pallets that do not require further processing and have a high-gloss surface treatment. In this plastic pallet manufacturing technology, the plastic pallet material and colorant are heated together to the required temperature (about 250°C). Usually, the heating is carried out in a barrel with a rotating screw. The plastic material is heated to the desired temperature and then injected into the mold, which is clamped under pressure. It is then allowed to cool and ejected. By using high pressure injection molding, the production time of the tray will be faster than any other molding method.

FAQs about pallet mold business

Can plastic pallet molds be customized?

Yes, each plastic pallet can be precisely customized to meet different industry needs. YUCO offers customization options in size, design, color, and additional features to meet your unique needs.

How long does it take to manufacture a plastic pallet mold?

The manufacturing time for a plastic pallet mold depends on various factors, such as complexity, size, and quantity. Our team is committed to providing efficient production times while ensuring that the highest quality standards are met.

What industries can benefit from using plastic pallets?

Plastic pallets are widely used in various industries due to their durability, versatility, and hygienic design, especially in the field of supply chain logistics. Other industries include retail, pharmaceutical, automotive, agriculture, manufacturing, etc.

Do you provide after-sales support for your plastic pallet mold products?

Yes, we provide comprehensive after-sales support to our customers. Our team is committed to ensuring that you are satisfied with our products and will assist you with any questions or concerns that may arise.

Get started on your plastic pallet project today!

YUCO is a leader in the plastic injection pallet mold industry. Our experienced team of engineers and designers have decades of combined experience in plastic pallet mold design and manufacturing. Not only do we provide one-stop service, specializing in the production of high-quality and high-precision pallet molds, we have also helped customers customize multiple types of plastic pallet molding lines.

We can also help you manage the entire production process. The plastic procurement department will purchase high-quality raw materials, while the technical department will select the appropriate plastic formula. According to the plastic pallet mold life requirements and market positioning, we will select the most suitable plastic pallet parameters, structure, etc. Our comprehensive production capacity enables us to deliver plastic pallets quickly, at competitive prices and with guaranteed quality.

Don’t let outdated pallet solutions hold your business back. Contact us today!

Tel: +86 13586040750