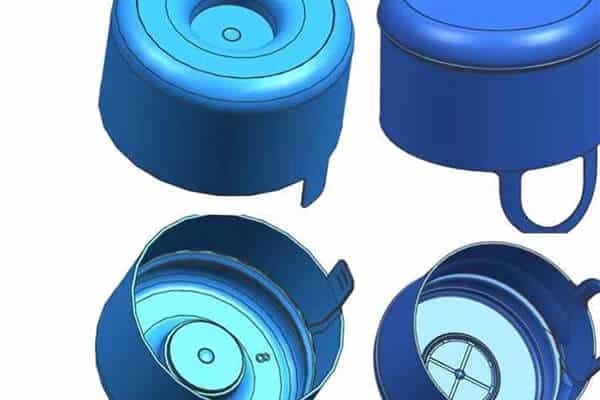

5 gallon cap mold

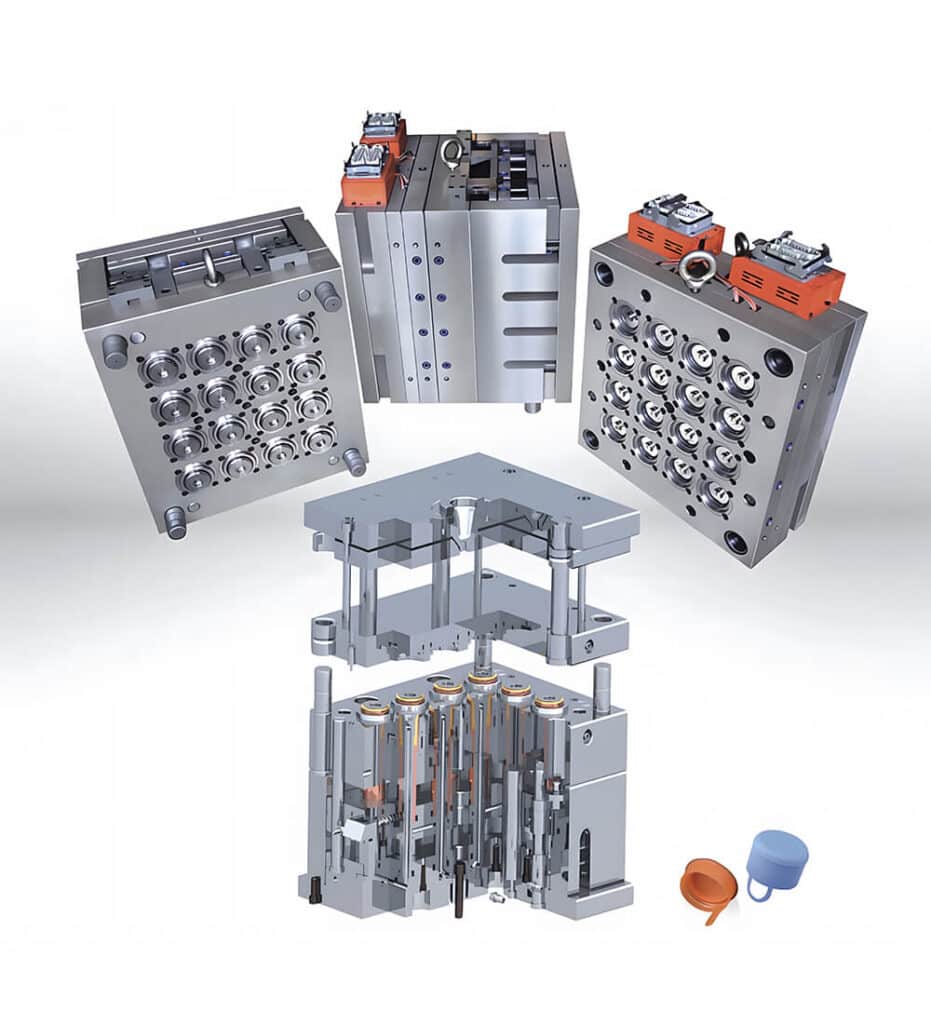

YUCO MOLD offers a variety of 5 gallon bottle cap molds to meet your specific requirements. We also offer fast delivery times and very competitive prices.

5 gallon cap molds from China manufacturer

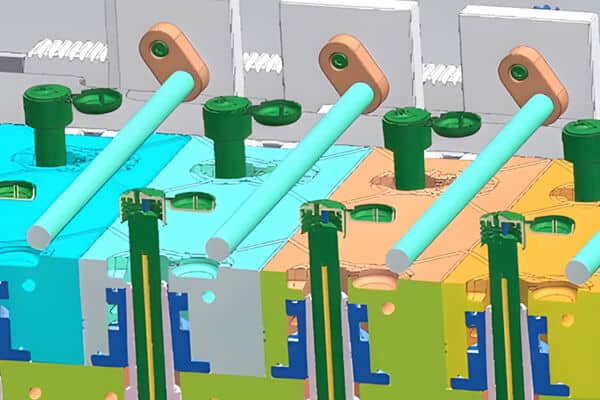

- The runner system can be selected from cold runner, semi-hot runner or hot runner system. Each cavity and core of the hot runner mold has an independent cooling system.

- The molding cycle of the product is a very important factor. The demolding adopts center ejection and blowing, and the cycle time is 16-18 seconds each time

- The mold core and cavity are heat-treated with German 2344 alloy, with a hardness of HRC 48-52°, and the mold frame is made of standard P20 material.

- Bottle caps have a variety of customized types, usually the bottleneck is a press neck, and the bottleneck diameter is 55 mm.

- Multi-cavity 5-gallon bottle cap mold is widely popular in the market due to its high production capacity. We are committed to providing 1-32 cavity multi-cavity 5-gallon bottle cap mold and making its technology mature.

5 gallon cap mold specifications

| Category | Specification | Details |

|---|---|---|

| Basic Specifications | ||

| Mold Type | Hot Runner Injection Mold | Advanced hot runner system with valve gate technology |

| Cap Type | 55mm 5-Gallon Water Bottle Cap | Compatible with standard 5-gallon water containers |

| Cap Dimensions | Outer Diameter: 55mm ± 0.05mm | High precision tolerance control |

| Inner Diameter: 49mm ± 0.05mm | ||

| Height: 22mm ± 0.05mm | ||

| Thread Specification | 55mm Buttress Thread Design | Enhanced sealing performance |

| Mold Construction | ||

| Mold Steel | Cavity & Core: STAVAX (Modified 420 ESR) | Superior corrosion resistance and polishability |

| Mold Base: P20 / 718H Pre-hardened Steel | Excellent durability and dimensional stability | |

| Sliders & Inserts: DC53 / SKD11 | High wear resistance | |

| Hardness | Cavity & Core: 50-54 HRC | Optimal hardness for extended mold life |

| Wearing Parts: 58-62 HRC | ||

| Cavity Number | 8-16 Cavities | Customizable based on production requirements |

| Mold Dimensions | 650mm × 650mm × 700mm | Compact design for efficient space utilization |

| Mold Weight | Approx. 2,500 kg | Robust construction |

| Technical Features | ||

| Runner System | Balanced Hot Runner System | Ensures uniform filling and consistent part quality |

| Nozzle Type: Thermal Gate/Valve Gate | Minimal vestige marks | |

| Cooling System | High-efficiency Conformal Cooling | 40% faster cooling time than conventional systems |

| Cooling Channels: 8-12mm diameter | Optimized for balanced cooling | |

| Cooling Water Temperature: 12-15°C | ||

| Ejection System | Hydraulic/Pneumatic Ejection | Consistent ejection force |

| Sequential Ejection Control | Prevents cap deformation | |

| Venting System | Precision Venting Channels | Prevents air traps and burning marks |

| Production Parameters | ||

| Applicable Resin | HDPE, PP, PC | Wide material compatibility |

| Cycle Time | 12-18 seconds | Industry-leading efficiency |

| Mold Lifespan | >1,000,000 cycles | Extended service life with proper maintenance |

| Clamping Force Requirement | 350-500 tons | Compatible with standard injection machines |

| Quality Assurance | ||

| Dimensional Tolerance | ±0.02mm | Exceeds international standards |

| Surface Finish | SPI-A1 to SPI-A2 (Cavity) | Mirror-like finish on visible surfaces |

| SPI-B1 (Technical Surfaces) | ||

| Testing Equipment | 3D CMM Inspection | 100% dimensional verification |

| High-speed Camera Inspection | Visual defect detection | |

| Leak Testing System | Ensures sealing integrity | |

| Certifications | ISO 9001:2015 | Quality management system |

| ISO 14001:2015 | Environmental management | |

| FDA Compliance | Food-grade safety | |

| Advanced Capabilities | ||

| Design Software | SolidWorks, AutoCAD, Moldflow | Comprehensive design and simulation capabilities |

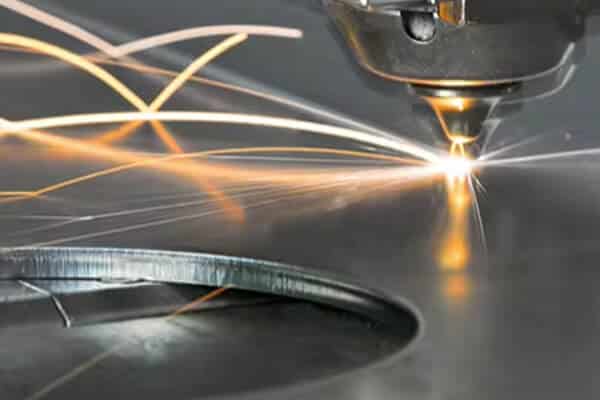

| Manufacturing | 5-Axis CNC Machining | Precision manufacturing for complex geometries |

| Wire-cut EDM with ±0.005mm precision | Ultra-precise component manufacturing | |

| Optional Features | Tamper-evident Design | Security features available |

| Custom Logo Embossing | Brand customization | |

| Anti-counterfeiting Technology | Product authentication features | |

| Service & Support | ||

| Lead Time | 30-45 days | Efficient production scheduling |

| Technical Support | 24/7 Online Support | Responsive customer service |

| On-site Installation & Training | Comprehensive implementation assistance | |

| Warranty | 1,000,000 shots or 1 year | Industry-leading guarantee |

China plastic cap mold manufacturer

5 gallon cap molding processing

5-gallon cap molds are a type of mold used to produce plastic caps for 5-gallon bottles and containers. These molds are an integral part of the production process and produce high-quality, durable caps that ensure a safe and reliable product.

01 Understanding Customer Needs

YUCO MOLD has extensive experience in manufacturing 5-gallon bottle cap molds. According to customer requirements, some 5-gallon bottle cap molds are made with hot runner systems, and some are made with cold runner systems. You can provide samples, or 2D drawings with accurate dimensions. 3D drawings are preferred.

02 mold design

Our bottle cap design team has at least 8 years of experience in 5-gallon bottle cap molding. They understand the appropriate bottle cap thickness, good tear system design, and achieve balanced injection. We will summarize the common problems of bottle cap molds and continuously optimize and improve on new molds. At present, our mold structure is very mature and stable.

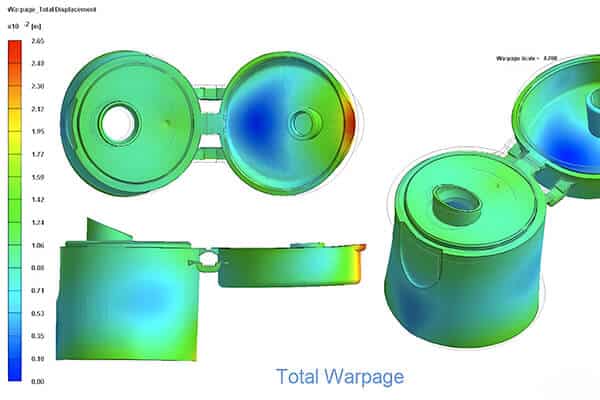

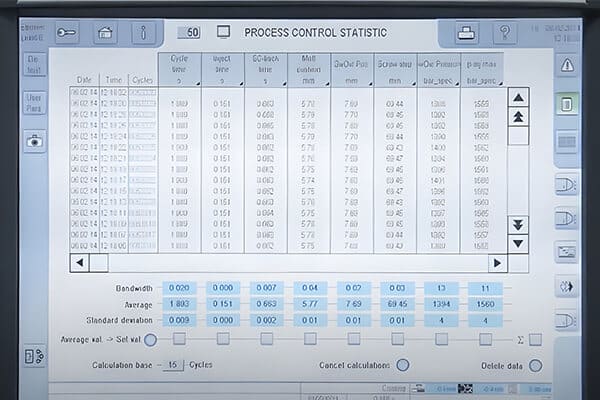

03 Analysis

We conduct comprehensive testing and analysis on product size, appearance, injection molding process and physical parameters. The analysis includes mold flow analysis, mold ejection, cooling system, rationality of guide system, mold part specifications, customer's machine selection and special requirements.

04 Meeting

The mold designer has recommended the appropriate steel for each mold component during the design. If the total cost is much higher than the customer's budget, the YUCO team will analyze and provide other solutions to ensure that the high quality expected by the customer is achieved.

05 mold processing

Reasonably select high-precision mold processing equipment, and the project follow-up team and QC department are responsible for the implementation of the entire project. The mold processing process is complete, from design to steel procurement, primary processing, inspection, finishing, assembly, testing, and sample inspection. The mold steel is heat-treated to ensure strength and service life.

06 Testing

YUCO MOLD will perform a leak test on the trial cap samples. The leak test needs to be kept for 24-48 hours. Obviously, this is a basic work to ensure that the 5-gallon cap is leak-proof.

06 technical support

Operational specifications, regular cleaning and maintenance can extend the service life of the mold. When we manufacture the mold, we also provide some additional wearing parts, such as O-rings, ejector pins, water pipe joints, springs, etc., to facilitate customers to replace basic wearing parts. After the mold is delivered, after-sales guarantee can usually be obtained within one year, and YUCO MOLD will provide technical support throughout the process.

Why choose YUCO 5 gallon cap mold

How to choose the right bottle cap mold for your business? You need to consider the operational needs and production goals of the business. In addition, the type and function of the bottle cap, material compatibility, and output should also be considered. At yuco mold, we specialize in providing high-quality 5 gallon water bottle cap molds to our customers. From design to manufacturing, we try to control and monitor every step to ensure that everything is done correctly.

Pricing

Customizability

material compatibility

One-step turnkey solution

Technical

Work experience

Two-color 5 gallon bottle cap mold

The above is a single color 5 gallon bottle cap mold, or a normal 5 gallon bottle cap mold. In addition, we are also able to produce a two-color 5 gallon bottle cap mold. With two-color injection molding, the sealing ring inside the bottle cap will be better. For the plastic material of the sealing ring, we can use TPR/TPE (food grade).

YUCO MOLD is an experienced two-color injection mold manufacturer. Even if you have no experience in the field of two-color injection molding, just tell us your needs and we can design the product for you, make the mold, and train your employees to operate the injection molding machine.

How to choose a 5-gallon water bottle cap mold?

Choosing the right 5-gallon water bottle cap mold is crucial. Every business has different operational needs and production goals. Here are some key factors to consider when choosing a bottle cap mold:

Cap type and function

The various bottle cap designs have different practical uses. Therefore, it is crucial to first determine which type of bottle cap is needed. These bottle caps include screw caps, flip caps, vented caps, or pop-up caps. Each type of bottle cap has its own advantages for consumers. For example, flip caps and pop-up caps are convenient for access, making them a common choice for homes and offices.

Cooling system

Ideal mold cooling is essential to ensure stable production of bottle caps at optimal capacity. It also ensures that the bottle caps solidify quickly after the molten material is injected, thereby increasing productivity. Carefully designed cooling channels in the mold help to shorten production cycles without compromising product quality.

Mold design

Mold design is crucial in mold development. Any errors in mold design will lead to problems in mold processing, which will in turn compromise mold quality and even take a long time to repair.

To make a high-quality 5-gallon bottle cap mold, a key factor is the appropriate tear ring design. It requires neither too thick nor too thin, so experience and skills are essential. If a mold maker has never made a bottle cap mold, we believe it is difficult for him to understand this technical difficulty.

Mold base

The mold base holds all the parts of the 5-gallon water bottle cap mold. It is usually used to provide support and stability throughout the production process. The size of the mold base design can vary depending on the size of the planned bottle cap.

Ejector system

Afterwards, in order to remove the bottle cap from the mold, each 5-gallon water bottle cap mold is equipped with an ejector system. These ejectors are usually used in most cases. They will leave a minimal ejector mark on the bottle cap. At the same time, it improves the efficient contact between the bottle cap and the mold.

Injection nozzle

This is where the molten material is first introduced into the mold. Ideally, the nozzle is located close to the cavity. This helps to achieve uniform material distribution.

Material compatibility

The ideal bottle cap mold should be compatible with the required material. Plastics such as HDPE, LDPE, and PP are the most commonly used materials for water bottle caps. Each plastic has its own practical characteristics. For example, their flexibility, strength, and sealing properties vary. Make sure the mold can adapt to these materials for the best results. The plastic raw material of the 5G bottle cap is LLDPE, which has high gloss, high heat resistance, and better fluidity than general materials.

Best mold steel

The most commonly used materials in bottle cap mold production are steel and aluminum. This is because they are hard, strong, and have a long service life.

We use S136 steel to make bottle cap mold cores and cavities, and P20 steel to make mold frames.

Applying the best (most suitable) mold steel to different mold components can also help save costs.

In addition, a hardness of 48-52 can effectively extend the life of the mold.

Durability and maintenance

The service life and maintenance of the 5-gallon water bottle cap mold should be durable enough to ensure long-term operation in a harsh production environment. Molds with corrosion-resistant and wear-resistant coatings are suitable for continuous use. Think about how long maintenance will take. Generally, the simpler the maintenance, the higher the production efficiency.

Production volume

What is the expected output of the bottle cap mold? Considering this can ensure that the correct mold size is selected. This is because larger-scale production usually requires molds with a large number of cavities. This is to achieve efficient mass production. Small batch production uses molds with a smaller number of cavities. This can increase manufacturing flexibility. YUCO molds are usually designed with 12 or 16 cavities, each with an independent cooling system to ensure better shaping and cooling of the product. In addition, the raw material has better fluidity, which greatly shortens the molding cycle.

Precision

This is important because it significantly affects the quality of the bottle cap. Therefore, they are equipped with advanced processing technology. This ensures the accuracy of the thread profile and sealing surface.

Get the best bottle cap molds from YUCO Mold

At yuco mold, we understand the importance of high-quality mold manufacturing. Therefore, we offer a wide variety of plastic bottle cap molds that are perfect for a variety of applications. Yuco bottle cap molds are made of high-strength steel to withstand the harsh production environment.

- Consultant service can help you choose the most suitable mold cavity and machine size to ensure that the mold runs perfectly on your machine

- Provide lightweight solutions for 5-gallon bottle caps to help you reduce production costs and get better profits.

- One-stop solution, in addition to molds, we can also provide one-stop solutions for 5-gallon assembly or labeling machines...

So, if you are looking for the best bottle cap injection molds on the market, yuco molds are your best choice. We are committed to helping you take your business to the next level.

Tel: +86 13586040750