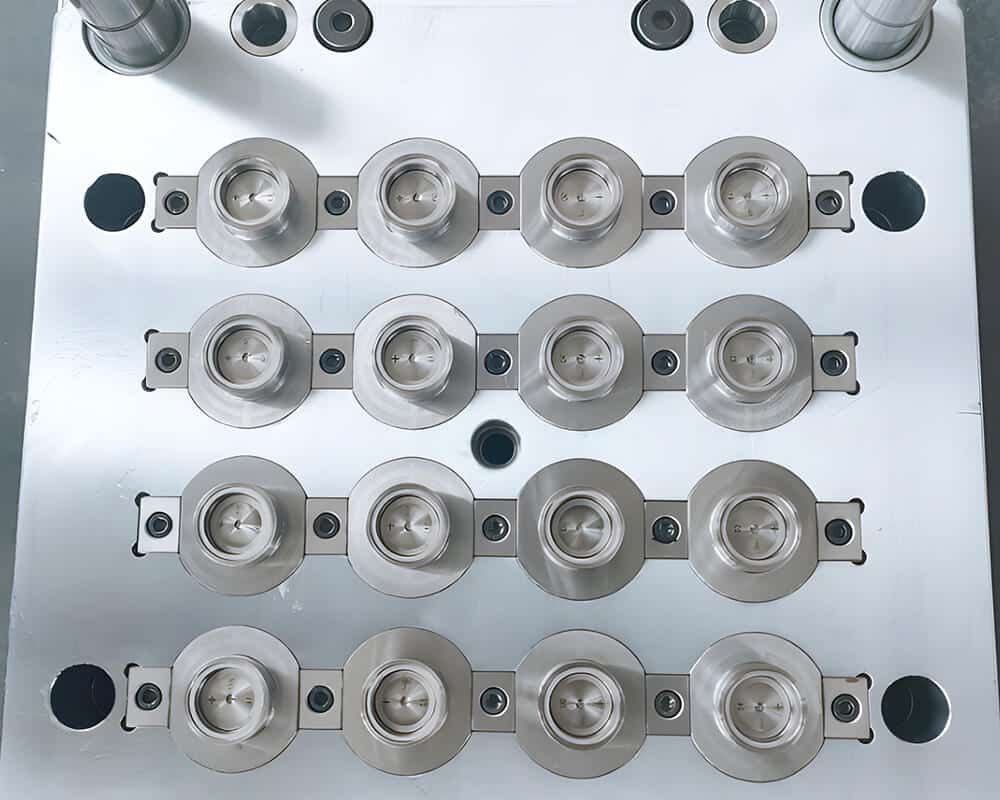

baby bottle cap mold

YUCO has a professional technical team dedicated to the production of baby bottle cap molds, which can design and manufacture molds quickly and efficiently.

baby bottle cap molds from China manufacturer

- The number of mold cavities ranges from 1 cavity to 48 cavities, depending on your choice.

- Adopt standard interchangeable parts, well polished, high hardness, corrosion resistance, to ensure the high precision and high quality of the mold.

- All parts are manufactured with advanced CNC equipment to ensure that each mold meets our strict quality standards.

- Independent temperature control and heating systems ensure uniform melt flow and pressure in all cavities, maintaining reliable and stable product quality

- Specially designed cooling channels eliminate leakage, and a good cooling system will improve production efficiency.

- The mold base is electroplated with chrome to effectively prevent rust and corrosion.

baby bottle cap mold specifications

| Specification Item | Description |

|---|---|

| Mold Type | Baby Bottle Cap Mold (Single cavity or multi-cavity, depending on production needs) |

| Material | High-quality steel (H13, P20, 1.2344) or stainless steel for long-lasting durability and resistance to wear. |

| Mold Base | Standardized or customized high-strength steel (S50C, S136) for better heat transfer and stability. |

| Injection System | Hot runner or cold runner system for efficient material flow, reducing waste and improving consistency. |

| Mold Surface Treatment | Nickel plating, chrome coating, or TiN coating for wear resistance, corrosion resistance, and smooth finish. |

| Mold Life | 1,000,000+ shots depending on material and surface treatment for high durability. |

| Tolerance | High precision, +/- 0.01 mm tolerance to ensure accurate fit and proper sealing of the baby bottle cap. |

| Cooling System | Optimized cooling channels for faster cycle time and temperature control, improving production efficiency. |

| Ejection System | Ejector pin or sleeve system designed for gentle part ejection to prevent damage to the cap. |

| Injection Pressure | Adjustable injection pressure (typically 800–1200 bar) for high precision and smooth molding. |

| Mold Cavities | Single or multi-cavity (4-8 cavities) mold for mass production or smaller batches depending on demand. |

| Clamping Force | High clamping force to ensure proper mold closure during injection. (Typically 80-200 tons, depending on size) |

| Cycle Time | 10-25 seconds (depending on complexity and material used), optimized for efficiency. |

| Safety Features | Design incorporates safety features such as a venting system to avoid material overflow and minimize defects. |

| Injection Materials | FDA-approved, BPA-free, food-safe plastic materials such as Polypropylene (PP), Polyethylene (PE), or PET. |

| Cap Functionality | Tamper-proof, child-resistant, leak-proof designs with excellent sealing to ensure safety and performance. |

| Mold Maintenance | Easy mold maintenance with removable inserts and precision alignment features for faster repair and upkeep. |

| Environmental Considerations | Sustainable mold production with minimal waste and energy-efficient processes to meet industry standards. |

| Lead Time | Typically 30-60 days depending on complexity, design, and quantity. |

China plastic cap mold manufacturer

baby bottle cap molding processing

Baby bottle cap molds are designed to produce highly durable, leak-proof, and easy-to-open caps. Injection molding is the most common method for manufacturing baby bottle caps because of its high precision and repeatability.

The two parts of this mold form a cavity into which molten plastic is pumped and then molded into the desired shape. Modern bottle cap molds are also very strong, usually made of high-strength mold steel to withstand the high temperatures and pressures during the molding process.

01 Understanding Customer Needs

YUCO MOLD has extensive experience in manufacturing baby bottle cap molds. According to customer requirements, some baby bottle cap molds are made with hot runner systems, and some are made with cold runner systems. You can provide samples, or 2D drawings with accurate dimensions. 3D drawings are preferred.

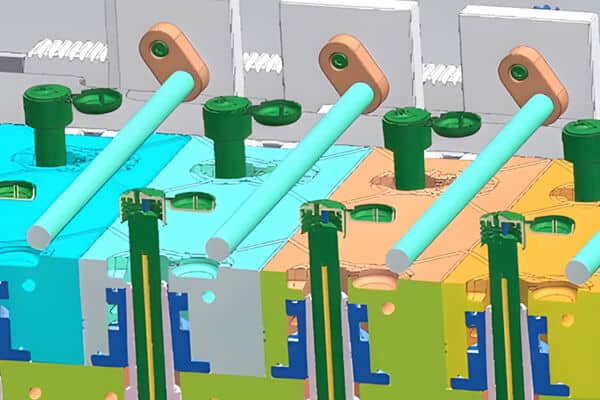

02 mold design

Our bottle cap design team has at least 8 years of experience in baby bottle cap molding. They understand the appropriate bottle cap thickness, good tear system design, and achieve balanced injection. We will summarize the common problems of bottle cap molds and continuously optimize and improve on new molds. At present, our mold structure is very mature and stable.

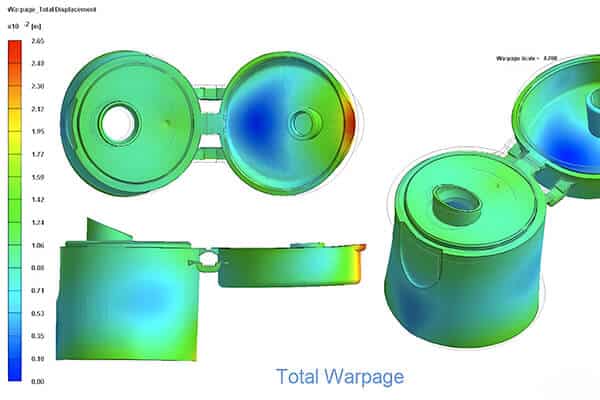

03 Analysis

We conduct comprehensive testing and analysis on product size, appearance, injection molding process and physical parameters. The analysis includes mold flow analysis, mold ejection, cooling system, rationality of guide system, mold part specifications, customer's machine selection and special requirements.

04 Meeting

The mold designer has recommended the appropriate steel for each mold component during the design. If the total cost is much higher than the customer's budget, the YUCO team will analyze and provide other solutions to ensure that the high quality expected by the customer is achieved.

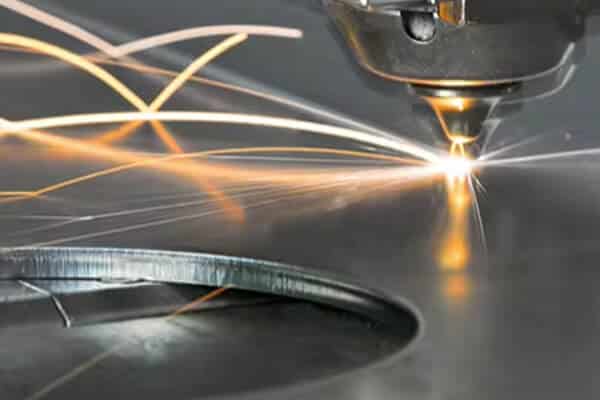

05 mold processing

Reasonably select high-precision mold processing equipment, and the project follow-up team and QC department are responsible for the implementation of the entire project. The mold processing process is complete, from design to steel procurement, primary processing, inspection, finishing, assembly, testing, and sample inspection. The mold steel is heat-treated to ensure strength and service life.

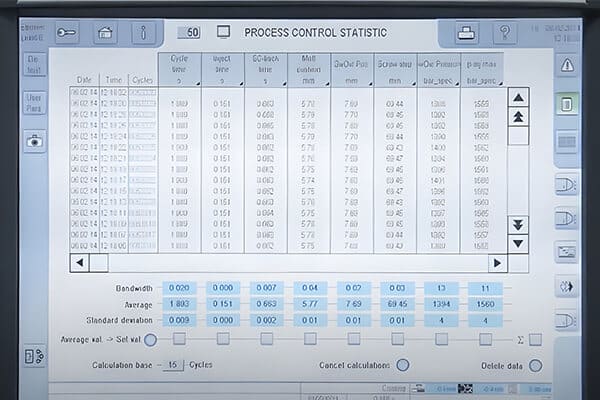

06 Testing

YUCO MOLD will perform a leak test on the trial cap samples. The leak test needs to be kept for 24-48 hours. Obviously, this is basic work to ensure that the baby bottle cap is leak-proof.

06 technical support

Operational specifications, regular cleaning and maintenance can extend the service life of the mold. When we manufacture the mold, we also provide some additional wearing parts, such as O-rings, ejector pins, water pipe joints, springs, etc., to facilitate customers to replace basic wearing parts. After the mold is delivered, after-sales guarantee can usually be obtained within one year, and YUCO MOLD will provide technical support throughout the process.

Why choose YUCO baby bottle cap mold

Pricing

Customizability

material compatibility

One-step turnkey solution

Technical

Work experience

Things to consider before buying a baby bottle cap mold

Production capacity of milk bottle cap mold

The mold must be able to withstand the number of uses required to produce the required number of baby bottle caps. Large-scale production may require the use of sturdy materials such as steel to manufacture milk bottle cap molds to withstand frequent use. This durability ensures a long service life of the mold and reduces the need for regular replacement, thereby maximizing production efficiency.

baby bottle cap mold gate system

Align the main gate with the parting surface between the cavity and the core in the inner hole of the molded plastic part and then open a runner on the end face of the core to feed the material in the form of a submerged gate. This main gate has two advantages: 1. The gate is relatively hidden and does not affect the appearance of the molded plastic part; 2. The gate material can be automatically trimmed to achieve fully automated production.

baby bottle cap mold demolding structure

The inner thread of the bottle cap must be demolded during the unscrewing process, and demolding cannot be forced. Before opening the mold, the oil cylinder drives the threaded gear to rotate and demold, and then during the mold opening process, the slider separates to realize product demolding. In order to extend the service life of the thread core and prevent wear, a copper sleeve is installed on the outer cylindrical surface of the thread core.

Materials used in molds

Manufacturing bottle cap molds requires a variety of materials to choose from, depending on the intended use and type of product being produced. Common materials have different properties, including steel, aluminum, and other alloys. The choice of material affects the performance, life, and cost-effectiveness of the mold, so manufacturers can customize bottle cap molds to their specific needs. As technology develops, composite materials are gradually being adopted to improve molding capabilities and reduce environmental impact.

Dimensional accuracy of baby bottle cap molds

The mold must accommodate the size of the bottle cap and all necessary characteristics. Cutting-edge technologies such as computer-aided design (CAD) and computer-aided manufacturing (CAM) can be used to improve the accuracy of bottle cap molds. , It can reduce material waste and ensure consistency in product size.

Mold cost

Injection molding is a complex process, and mold costs can be high. However, we provide affordable options for customers with limited budgets.

Yuco mold: China's trusted baby bottle cap mold manufacturer

We are a well-known bottle cap mold manufacturer, producer and supplier in China. Our products are widely used in food packaging, daily packaging, chemical packaging, agricultural product packaging, pharmaceutical packaging and other industries.

Contact us now for more information about our products and services, or request a quote.

Tel: +86 13586040750