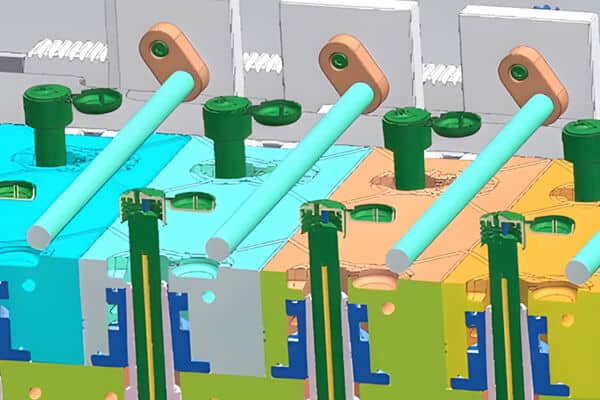

cosmetic cap mold

At YUCO Mold, we specialize in manufacturing high-quality cosmetic bottle cap molds. They are carefully designed to be compatible with a range of cosmetic grade materials, ensuring durability and hygiene for your premium products.

Plastic cosmetic cap molds from China manufacturer

- Our mature design team with decades of experience can realize a variety of bottle cap styles, sizes and closure mechanisms to flexibly meet the different packaging needs of cosmetics.

- We aim to create bottle caps that meet the complex aesthetic requirements of the cosmetics industry, providing stylish, modern and customizable options. To ensure that our customers get the exact products they need.

- YUCO's cosmetic bottle cap mold supports two-color design, and we use a large number of complex two-color mold structure designs to achieve high-end, qualified quality.

- The market demand for cosmetic bottle caps is large, and the production batch is huge, so we generally use multi-cavity molds, and the number of cavities can reach 1-36 cavities under current technical conditions.

cosmetic cap mold specifications

| Specification Category | Parameter | Typical Value/Range | Remarks |

|---|---|---|---|

| Mold Material | Core & Cavity Steel | Pre-hardened: P20 (1.2311), P20+Ni Hardened: H13 (1.2344), 2344, NAK80, S136 Stainless: ASSAB Stavax |

Selection based on budget, production volume, and material compatibility |

| Mold Base Steel | S50C, P20 | Selection based on budget and requirements | |

| Core & Cavity Hardness | Pre-hardened: HRC 30 32±1 Hardened/Heat Treated: HRC 48 52±1 |

Influences mold life and wear resistance | |

| Basic Dimensions | Mold Dimensions | Varies based on cap design | Typically smaller than laundry basket molds |

| Product Dimensions | Diameter: 15-50mm (Example) Height: 10-30mm (Example) |

Dependent on specific cap design | |

| Mold Structure | Number of Cavities | 4, 8, 16, 32, or more | High cavitation for mass production |

| Parting Line | Typically stepped or angled | For complex cap designs, optimized for aesthetics and ejection | |

| Runner System | 1. Hot runner (preferred) 2. Valve gate hot runner | Ensures balanced flow and minimal gate vestige | |

| Core Pulling/Ejection System | Ejector pins, stripper plates, unscrewing mechanisms (for threaded caps) | Dependent on cap design features | |

| Technical Parameters | Mold Weight | Varies based on size and cavitation | Typically less than laundry basket molds |

| Injection Pressure | 60-150MPa | Depends on material and cap design | |

| Mold Temperature | 20-60℃ | Material dependent (PP, PE, ABS, etc.) | |

| Cooling Time | 5-20s | Optimized for fast cycle times | |

| Design Features | Cooling System | Close-circuit cooling with strategically placed cooling channels | Efficient cooling for high-volume production |

| Mold Accessories | Compatible with DME/HASCO standards | Standardized components for maintenance and interchangeability | |

| Venting System | Precise venting design for trapped air and gases | Prevents short shots and burn marks | |

| Tamper-Evident Feature (Optional) | Integrated into the mold design | Breakaway bands or other tamper-evident features | |

| Surface Finish | Surface Treatment | Texturing, polishing, high-gloss finish | Achieves desired cosmetic appearance |

| Surface Roughness | Ra < 0.4μm (for high-gloss finishes) | Critical for cosmetic appeal | |

| Dimensional Tolerance | ±0.05mm | High precision required for proper fit and function | |

| Mold Life | Pre-hardened Steel | 100,000 – 500,000 shots | Depending on material and operating conditions |

| Hardened/Heat Treated Steel | 1,000,000+ shots | With proper maintenance | |

| Application Parameters | Applicable Injection Molding Machine | 50-300 tons | Based on mold size and cavitation |

| Product Material | PP, PE, ABS, PET, etc. | Wide range of resin options for various applications | |

| Cycle Time | 10-30s | Fast cycle times for high productivity | |

| Delivery & Service | Delivery Time | 60-90 days | T1 samples provided |

| Packaging | Standard wooden case, vacuum packed | Protecting the polished surfaces | |

| Production Service | Pilot run and molding production available | Complete production solutions |

China plastic cap mold manufacturer

cosmetic cap mold processing

Injection molding is a method of quickly and efficiently producing large quantities of identical cosmetic bottle caps. One advantage of injection molded cosmetic bottle caps is that they can be made into a variety of shapes and sizes. Another advantage is that cosmetic bottle caps can be made from recycled plastic, which helps reduce the impact on the environment.

In this process, molten plastic is injected into the cosmetic bottle cap mold, cooled, and hardened to form the desired shape. The mold is then opened and the cosmetic bottle cap is ejected.

01 customization

For cosmetic bottle caps, it is important to have an attractive design. We can make a two-color mold for our customer to help him realize his idea.

02 mold design

YUCO Mold specializes in custom mold design and manufacturing for the bottle cap industry. We have been working with some of the biggest names in the cosmetics industry for over a decade and can create molds to meet your specific needs.

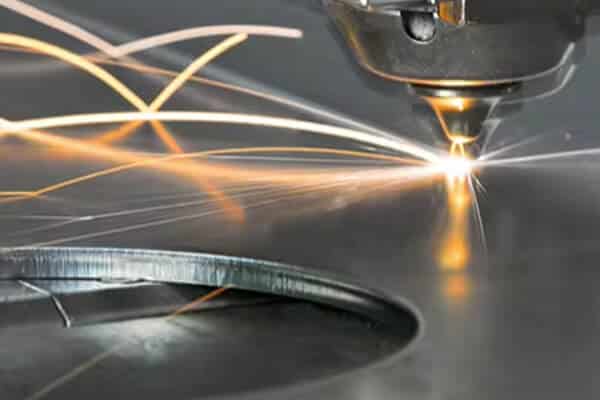

03 mold manufacturing

Our experienced mold manufacturing team ensures that each mold meets the highest quality standards. Cosmetic packaging cover molds with superior quality and precision ensures that your products stand out in a competitive market.

04 mold inspection

Our modern, fully-equipped mold shop is capable of producing molds that meet the highest SPI standards. In addition, we offer customizable surface finishes, from gloss to matte, to achieve the visual and tactile appeal required for cosmetic caps.

05 mold testing

Our experts will also adjust the mold until you are satisfied with the product produced by it, which means creating multiple test samples to ensure that the mold works exactly as expected.

06 Packaging and shipping

1. Test mold before shipment 2. Mold inspection, take mold photos 3. Spare parts, mold drawings packed in wooden box with mold

Why choose YUCO cosmetic cap mold

Partnering with YUCO, a Chinese plastic mold manufacturer, for production offers customizable designs, cost-effectiveness, and efficient delivery. A reliable manufacturer can provide expertise and tailor-made solutions to improve your manufacturing and processing efficiency.

Tight tolerances

Pricing

Customization

Quality control

8/24x7 Service

10,000+ Capacity

Frequently asked questions

What is a cosmetic bottle cap mold?

A cosmetic bottle cap mold is a special mold that is used to make cosmetic bottle caps. Bottle caps are usually made of plastic, and molds help to mold the plastic into the desired shape. Cosmetic bottle cap molds come in various sizes and shapes, depending on the type of bottle used.

The requirements for cosmetic bottle caps are exquisite and beautiful appearance, unique feel and texture, and ingenious and meticulous design. Cosmetic cream bottle cap products are the most widely used in cosmetic packaging. The plastic parts themselves must not have injection defects such as weld marks, bubbles, deformation, color difference, burrs, etc.

Considerations for efficient, precise and durable cosmetic bottle cap molds

Molds help mass produce cosmetic bottle caps in a short time. Molds are important for manufacturing cosmetic bottle caps for the following reasons.

- High precision: Ensure the accuracy of cavity processing, so that the tolerance of each cavity size is controlled within 0.015, and ensure the interchangeability of the cavity. The mold frame processing accuracy also needs to be improved, and the tolerance of the center distance of each cavity is controlled within ±0.015.

- Surface treatment: The mold needs to be achieved using high diamond polishing. It is also recommended to use flash chrome to protect the surface, so that the mold can run longer between maintenance inspections and produce more flawless and uniformly sized parts.

- Durable structure: Made of durable mold base material (steel or aluminum) to extend the life of the mold and achieve efficient heat dissipation during the molding process. For high quality and mass production, we recommend using S136 steel and NAK80 steel

- Efficient runner system: It has a well-designed runner system to optimize material flow and ensure consistent and perfect molding results.

- Optimize the gate system: Provide a customizable gate system that can accurately control the material entry point and size to achieve the best molding results. The gate is generally designed on the back of the product or the inner surface of the bottle cap, and is covered with a gasket or other parts.

- Plastic bottle cap ejection method: 1. The plastic bottle cap is ejected by forced demolding, which is relatively simple in the design of the ejection system. However, if the cooling time of this forced demolding design is not enough, it is easy to damage the thread of the plastic bottle cap, resulting in failure to assemble with the bottle body. 2. When the bottle cap thread height is high and the plastic material is more rigid, a gear system needs to be designed to eject the bottle cap from the cavity. The structure of the gear system requires the design of the arrangement of gears, transmission gears, the center shaft with the gear system, and the ejection system. It is necessary to calculate how many turns the gear needs to be removed and how much length the transmission rack needs to pass. The steel of the unscrewing device must be made of high-end material and heat-treated to avoid wear during short-term movement.

Why choose YUCO molds for cosmetic cap molds?

Our state-of-the-art cosmetic bottle cap molds are carefully designed to meet the rigorous standards of the cosmetic industry. Our bottle cap molds are precisely designed and versatile, ensuring seamless production of high-quality bottle caps that enhance the aesthetics of your packaging.

We understand how important it is for manufacturers like you to find a reliable partner that provides high-quality molds, and that's where we come in. Starting with your design and material, you can decide if injection molding is right for you and what mold material you want. Molds made of iron and other materials are available.

Fill out our online form to order cosmetic bottle cap molds from YUCO Mold. In the form, you will need to provide basic information about your business and the mold you need. Once we have this information, one of our representatives will contact you to discuss your specific needs and provide a quote.

Tel: +86 13586040750