flip top cap mold

YUCO MOLD designs, manufactures and exports high-quality flip cap molds to serve customers worldwide. We have accumulated rich experience in manufacturing various flip cap molds from 1 cavity to 72 cavities, and can customize shampoo flip cap molds, lubricant flip cap molds, ketchup flip cap molds, etc. according to customer's product design.

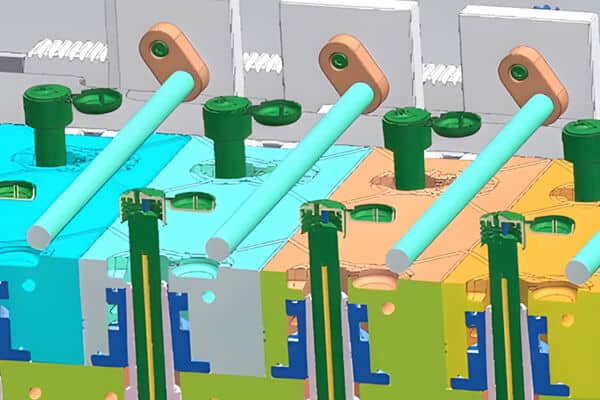

flip top cap molds from China manufacturer

- We pay great attention to mold quality and can provide proof of material origin and material original heat resistance. Materials with high purity, good toughness and good polishing are preferred.

- The high-performance hot runner system uses German heating components, and each cavity is independently heated and controlled to ensure uniform melt flow and pressure in all cavities. Independent cooling system to shorten the production cycle.

- Each cavity is interchangeable, which is convenient for replacing the company logo on the bottle cap.

- Each mold is electroplated and has a very long anti-rust effect. The mold has a long life and is guaranteed to last more than 5 million injections.

flip top cap mold specifications

| Specification Category | Parameter | Typical Value/Range | Remarks |

|---|---|---|---|

| Mold Material | Core & Cavity Steel | NAK80, S136 (STAVAX), 2738, H13 (1.2344) Stainless steel for food/cosmetic applications | High-grade steel required for complex geometry and wear resistance. |

| Slider/Lifter Components | SKD61, S136, NAK80 | Wear-resistant materials for moving components. | |

| Mold Base Steel | P20, LKM Standard Mold Base | Robust base to support complex internal mechanisms. | |

| Core & Cavity Hardness | HRC 48~54±1 | Higher hardness preferred for precision components and extended life. | |

| Basic Dimensions | Mold Dimensions | Varies based on cap design and cavitation. | Typically larger than standard cap molds due to sliding mechanisms. |

| Product Dimensions | Overall cap diameter: 20-60mm Overall height: 15-40mm Hinge thickness: 0.3-0.8mm | Dimensions vary widely based on application (personal care, food, etc.). | |

| Mold Structure | Number of Cavities | 8, 16, 32, 64, 96 (common) | Lower cavitation than standard caps due to complexity. |

| Parting Line | Multiple parting surfaces Complex split lines for lid and base | Requires precise alignment of multiple components. | |

| Runner System | Hot runner system (preferred) Sequential valve gating | Balanced filling critical for consistent hinge formation. | |

| Slider Mechanism | Hydraulic or mechanical sliders Angular lifters/slides: 2-8 per cavity | Essential for molding undercuts and facilitating part release. | |

| Core Pulling/Ejection System | Multi-stage ejection sequence Dedicated ejectors for lid and base Synchronized ejection timing | Precise ejection prevents damage to delicate hinge areas. | |

| Technical Parameters | Mold Weight | 1.5-2.5x heavier than standard cap molds | Additional weight from slides and mechanisms. |

| Injection Pressure | 100-220 MPa | Higher pressure often required for complex flow paths. | |

| Mold Temperature | 30-70°C | Precise temperature control for consistent hinge formation. | |

| Cooling Time | 8-22s | Extended cooling for dimensional stability of hinge. | |

| Design Features | Cooling System | Independent cooling circuits for: – Cap body – Flip lid – Hinge area – Slider components | Differential cooling rates critical for part quality. |

| Hinge Design | Living hinge (0.3-0.5mm thickness) Mechanical hinge Spring-assisted mechanism | Design based on required opening force and cycle count. | |

| Locking Mechanism | Snap-fit engagement Friction fit Positive locking | Designed for specified opening/closing force. | |

| Venting System | Precision micro-vents in lid, body, and hinge areas | Critical for preventing burn marks and short shots in thin sections. | |

| Surface Finish | Functional Surfaces | SPI-B1/B2 (Ra 0.4-0.8μm) | Areas requiring smooth operation. |

| Aesthetic Surfaces | High polish (SPI-A2/A3) Textured finish options | Visible areas with cosmetic requirements. | |

| Hinge Area Finish | SPI-B1 (Ra ~0.5μm) | Smooth finish essential for hinge durability. | |

| Dimensional Tolerance | ±0.02-0.03mm for critical mating surfaces ±0.05mm for general dimensions | Precision alignment required between lid and body. | |

| Mold Life | Expected Shots | 500,000-1,000,000 shots | Dependent on material, maintenance, and design complexity. |

| Maintenance Cycle | Cleaning/inspection every 100,000 shots | Regular maintenance essential for sliding components. | |

| Application Parameters | Applicable Injection Molding Machine | 100-350 tons | Higher tonnage required for multi-cavity tools with slides. |

| Product Material | PP, PE, PC/ABS blends Materials with high flex modulus for hinges | Material selection critical for hinge performance. | |

| Mold Open Stroke | 50-80% greater than standard caps | Additional clearance needed for part ejection. | |

| Cycle Time | 12-30 seconds | Longer cycle due to complex ejection sequence. | |

| Delivery & Service | Delivery Time | 90-120 days | Extended timeframe due to complexity. |

| Testing Requirements | 10,000+ cycle hinge durability testing Closing force testing Drop testing | Functional testing critical for hinged components. | |

| Packaging | Custom wooden crates with individual component protection Anti-corrosion coating | Careful packaging to protect precision components. | |

| Documentation | Detailed assembly drawings Maintenance manual Cooling circuit diagrams | Comprehensive documentation for complex tool. |

China plastic cap mold manufacturer

flip top cap molding processing

Injection molding is one of the most commonly used manufacturing processes for producing complex and precision products such as clamshells. The process involves injecting molten plastic into a mold to form it into the desired shape.

The mold plays an integral role in injection molding. Highly sophisticated molds must be designed and manufactured to mass produce clamshells with complex designs and features.

In addition, experience in injection molding machine settings is essential, including the setting of injection speed and pressure. Only by taking all factors into consideration can a high-quality clamshell mold be produced.

01 Understanding Customer Needs

First, customers need to contact us with detailed information about the mold they need, including size, material, and accessories required. Once we receive this information, we will provide a quote and delivery time for mold production.

02 mold design

Flip top cap mold design is very important. The design of the bow/hinge determines whether the flip cap can open or close smoothly. Many other parts, such as the parting line, shrinkage are also considered. Our design team will work with you to create the perfect mold for your needs. Once the design is completed, our engineers will meet to discuss the mold's motion plan to improve the mold structure.

03 analyses

We conduct a full range of tests and analyses on product size, appearance, injection molding process and physical parameters. The analysis includes mold flow analysis, mold ejection, cooling system, rationality of guide system, application of mold part specifications, customer machine selection and application of special requirements.

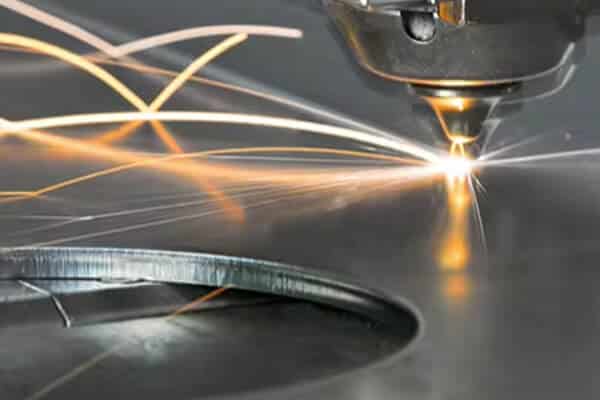

04 mold manufacturing

We have a series of top CNC machine tools, such as EDM machines, engraving machines and other high-precision processing equipment to ensure full CNC, efficient and precision manufacturing of key components. Our professional technicians ensure that each mold is carefully crafted and pays attention to details. After that, the mold is assembled in our demanding and technically sophisticated workshop.

05 testing and production

At YUCO Mold, quality control is the top priority in the mold manufacturing process. We will not only trial produce the bottle caps you currently need, but also conduct various durability tests to simulate actual usage scenarios to ensure the life and functionality of the mold.

06 Packaging and shipping

We have excellent mold manufacturing lead time, depending on your part design. Before the mold is exported, we will disassemble all mold components for final inspection. We even provide after-sales service to deal with any adjustments or maintenance that may be needed in the future.

Why choose YUCO flip top cap mold

Flip cap is one of the commonly used cap types for plastic bottles. For a good flip cap, there should be a sound when pushing the flip cap, and it should be able to open quickly by itself when we open the flip cap to a certain position. This requires the flip cap to have a butterfly design, and also requires the flip cap to have suitable raw materials, and it must have a waterproof function when the flip cap is closed with the bottle. YUCO's flip top cap mold means that high-quality flip caps with the same quality can be produced, and the flip cap mold can be fully automatic, with high production efficiency.

Pricing

Customizability

material compatibility

One-step turnkey solution

Precision

production volume

Two-color flip cap mold

We regularly review and update our technology to meet industry standards and meet the unique needs of our customers. The two-color flip cap mold uses advanced single-mold two-color technology, which means that two different colors of materials can be injection molded in the same mold. This technology not only improves production efficiency but also ensures product consistency and precision.

This high-precision manufacturing requires:

- Complete technical team: Have our own mold design, mold manufacturing and injection molding team

- Professional equipment support: Equipped with two professional two-color injection molding machines, mold testing can be performed

- Customer technical support: Provide customer engineer training to ensure maximum mold use effect

flip top bottle cap mould design

Cavity arrangement

There are 8 cavities in a plastic part, and it is mass-produced. It is divided into two rows based on the force balance of the oblique slider and the oblique wedge, and each row has four holes. This mold base is a non-standard 4545 thin nozzle straight body mold base, A85 B30 C118. For increasing mold clamping accuracy, all template materials are 2083H; four PL-75T positioners are added to the mold base; ball guide bushes are added to the push plate; four dia.

It adopts an oil-free linear guide column for the middle support, the straight support side and the center support.

Design of gating system

Molten plastic flows slowly through one mold out of eight. This is why a hot nozzle is used to feed glue, and molten plastic passes through fine filters.

Each mold cavity has its own nozzle gating system, which is located at the edge of its lower cover and is blocked when the upper cover is closed. When the mold is opened, the condensate from the runner system is ejected from part 17.

Design of lateral core-pulling mechanism

A lateral core-pulling mechanism with an inclined angle of 35° must be designed for the upper cover of the plastic part. The upper cover sticks to the slider because of the glue on the edge and the center column. The slider spring pin (slider thimble) is designed to solve this issue. T-shaped slots drive the sliders, and locking wedges control the opening and locking.

Ejection system design: like three ejections

When the injection molding machine ejects the ejector pin for the second ejection, the plastic part is placed in the core inserts 1 and 2 during the ejection action. After disengaging from the movable inner mold, the core insert 2 is halted by the round nut to stop movement, and the semicircular undercut is successfully released. Once the plastic part is separated from the core insert 2, the final plastic part is ejected from the core insert 1.

Mold opening sequence

Control mold opening sequence with multiple buckle machine groups. The nozzle plate needs to be opened first before the AB plate. The nozzle material must be removed, the core pulled, and the parting surface opened. According to the ejection sequence, the rear mold opens.

Get reliable flip top cap molds from YUCO Mold

YUCO Mold is your trusted mold manufacturer. Our company has many years of experience in manufacturing molds for different application areas and provides them at very competitive prices. On our website, you can find the molds you need to make all kinds of bottle caps.

We strictly control the quality of each mold from design to shipment. Our flip cap molds only require simple maintenance and customers can run the mold without stopping. Now most of the molds are still running well.

If you have a new plan to invest in the plastic flip top mold industry, welcome to contact us, we will provide you with preferential prices and convenient services.

Tel: +86 13586040750