olive oil bottle cap mold

YUCO Mold is a leader in the field of customized injection molding oil cap molds in China, such as edible oil bottle caps and olive oil bottle caps in the food industry. Hot runner or cold runner structure can be selected according to customer requirements.

olive oil bottle cap molds from China manufacturer

- YUCO MOLD analyzes the structural characteristics of olive oil caps, gives the principles and processes of cap injection mould design and manufacturing, and on this basis proposes the master mould demoulding method and two-stage ejection mechanism.

- Excellent heat treatment is adopted in the process. Special coating process is adopted after heat treatment. The external part is wear-resistant, the internal structure is not deformed and wear-resistant, and the mould has a long life.

- Our molds are made of high-hardness high-quality steel. Our accessories and hot and cold runners are also made of imported or high-quality materials. The mold accessories are of high precision and well matched with each other.

- The design of the cooling system is also fully in line with the standards and very reasonable. The heat conduction and heat dissipation are fast, so that the bottle cap can be cooled quickly and the production efficiency can be improved.

- The oil cap mold adopts advanced hot runner design, with uniform heating temperature, which effectively improves the quality of plastic products.

olive oil bottle cap specifications

| Specification Category | Parameter | Typical Value/Range | Remarks |

|---|---|---|---|

| Mold Material | Core & Cavity Steel | S136 (STAVAX)/420 stainless steel (preferred) NAK80/H13 (1.2344) for high-end finishes P20+Ni for lower volume |

Stainless steel preferred due to food-grade requirements and corrosion resistance. |

| Mold Base Steel | P20, S50C | Standard mold base materials. | |

| Core & Cavity Hardness | Hardened: HRC 50 54±1 Pre-hardened: HRC 32 34±1 |

Higher hardness preferred for premium finishes and longevity. | |

| Basic Dimensions | Mold Dimensions | Varies based on cap design and cavitation. | Typically compact for specialized caps. |

| Product Dimensions | Diameter: 18mm, 28mm, 31.5mm (common) Height: 10-25mm (typical) |

Often includes pouring spout or anti-drip features. | |

| Mold Structure | Number of Cavities | 1, 2, 4, 8, 16 (common) | Lower cavitation for premium caps with complex features. |

| Parting Line | Precision-designed, often multiple parting surfaces | Carefully positioned to minimize visible parting lines on finished product. | |

| Runner System | Hot runner system (preferred) Valve gate hot runner for premium finishes |

Minimizes gate vestige for aesthetic requirements. | |

| Core Pulling/Ejection System | Hydraulic/pneumatic unscrewing mechanisms for threaded caps Precision ejector pins for non-threaded designs |

Complex ejection systems for specialized designs (pour spouts, flip-tops). | |

| Technical Parameters | Mold Weight | Varies based on size and cavitation. | Typically compact compared to other packaging molds. |

| Injection Pressure | 90-200 MPa | Higher precision requirements demand controlled pressure. | |

| Mold Temperature | 25-65℃ | Optimized for selected resin and surface finish requirements. | |

| Cooling Time | 6-18s | Balanced for quality and production efficiency. | |

| Design Features | Cooling System | Conformal cooling channels with beryllium copper inserts for critical areas | Uniform cooling prevents warpage and ensures dimensional stability. |

| Mold Accessories | Premium DME/HASCO standard components | High precision components for extended mold life. | |

| Venting System | Precision micro-venting (typically 0.01-0.02mm depth) | Critical for preventing burn marks on visible surfaces. | |

| Specialized Features | Pour spout inserts Anti-drip design Tamper-evident seals |

Often requires multi-component assembly in the mold. | |

| Surface Finish | Surface Treatment | Mirror polishing (SPI-A1/A2) Micro-texturing Selective matte/gloss finishes |

Premium aesthetic requirements for high-end olive oil packaging. |

| Surface Roughness | Ra < 0.2μm for mirror finish areas Ra 0.5-1.0μm for textured areas |

Extremely fine finish for premium appearance. | |

| Dimensional Tolerance | ±0.03mm | Tighter tolerances for precise fit and guaranteed sealing properties. | |

| Mold Life | Premium Steel (S136/NAK80) | 1,000,000+ shots | Premium steels selected for extended mold life. |

| Standard Steel (P20+Ni) | 300,000 – 800,000 shots | With proper maintenance and storage. | |

| Application Parameters | Applicable Injection Molding Machine | 60-250 tons | Dependent on cap design complexity and cavitation. |

| Product Material | PP, PE, PET, Biopolymers Food-grade materials with FDA/EU approval |

Materials must be inert and not affect oil quality or taste. | |

| Cycle Time | 10-25 seconds | Balanced for quality and efficiency. | |

| Delivery & Service | Delivery Time | 70-100 days | Includes stringent quality control and testing. |

| Packaging | Vacuum sealed with rust preventative Custom wooden crates with shock absorption |

Extra protection for polished surfaces and precision components. | |

| Production Service | Low-volume pilot runs Full production services Quality certification documentation |

Complete package including quality documentation for food-grade applications. |

China plastic cap mold manufacturer

olive oil bottle cap processing

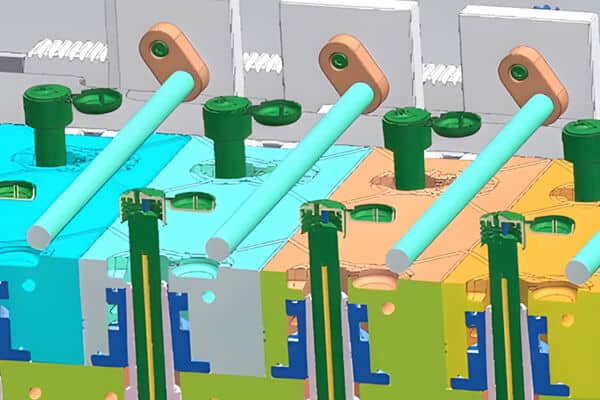

From the overall structure and assembly drawing of the mold, the mold is mainly divided into two parts: the movable mold and the fixed mold. The olive oil bottle cap mold adopts a one-mold four-cavity structure, and the cavities are distributed in one piece, with a total of 4 cavities, but the shapes of the cavities are different. The gate is generally designed with a side gate.

Install the olive oil bottle cap mold on the injection molding machine, and then adjust the injection molding process. Required parameters. During the injection molding process, the plastic melt is injected into the mold cavity along the gating system at a certain injection pressure. After the mold is opened, fix the fixed mold part on the connecting plate. Move the fixed mold part backward.

01 Understanding Customer Needs

After understanding the requirements of the bottle cap, we can make the cap mold accordingly, such as considering the quality, material, cavity, price, delivery time, payment period, etc.

02 mold design

After being familiar with the specifications and requirements of the water bottle cap, our mold design team will make the best mold design. 2D & 3D mold design (CAD, UG, SolidWorks, ProE, etc., 2D drawings: DXF, DWG, PDF files, 3D models: IGS, PRT, XT, free electronic drawings.)

03 mold manufacturing

After you confirm the mold design, we will start making the mold. YUCO MOLD has reliable mold processing capabilities, which can process the drawings well into absolutely perfect mold parts.

04 testing and production

For this kind of mold, machine settings are very important, including the settings of injection speed and pressure. Only when we consider all factors can we get high-quality water bottle cap molds.

05 Packaging and shipping

1. YUCO conducts strict mold quality control for each process! 2. Mold inspection, take mold photos 3. Spare parts, mold drawings packed in wooden box with mold

Why choose YUCO olive oil bottle cap mold

Oil bottle cap molds are widely used in daily life. Oil bottle caps are divided into food and non-food categories according to functional areas, such as edible oil bottle cap packaging and olive oil bottle cap packaging in food packaging. In the industrial field, they are used for automobile oil bottle packaging, automobile engine oil bottle packaging, and some CNC machine tool oil bottle packaging. According to the appearance, they are divided into flip-top series and two-part assembly series. The mechanism of the oil bottle cap usually has high requirements for the production process.

Customizability

material compatibility

production volume

Frequently asked questions

Olive oil bottle cap mold design considerations

When designing the olive oil bottle cap injection mold, according to the structural characteristics, a 1-mold 4-cavity structure is selected. The olive oil bottle cap mold adopts a fixed mold core floating and secondary ejection structure to ensure smooth demolding. The upper and lower openings adopt an inverted structure.

In addition, the slider adopts a forced reset mechanism to lock the mold smoothly. After testing, the mold structure is reasonable and the produced plastic parts meet our quality requirements.

The olive oil bottle cap mold pouring system includes a main runner, a primary runner, a secondary runner, a tertiary runner and a gate. In this process, the sleeve is formed, the primary runner is processed on the fixed mold plate, and the secondary and tertiary runners are processed on the vertical parting surface. For ease of processing, the plate runner adopts a trapezoidal cross-section and the slider runner adopts a circular cross-section.

As part of the mold temperature control system, the fixed mold part is opened on the fixed mold plate, and the movable mold part is circulated and cooled by the baffle closing slider, and the mold temperature is kept within the required range by circulating cooling water. In the mold exhaust system, the air mainly acts between the baffle closing slider and the core, which is called gap flow.

Why choose YUCO molds for olive oil bottle cap?

The team of YUCO MOLD is committed to developing excellent performance bottle cap injection molds to provide customers with the greatest convenience and the best experience.

YUCO integrates advanced technology and raw material resources, focusing on product application technology research. We have advanced testing equipment and perfect technical means to ensure the excellent product performance of olive oil bottle cap molds. With modern management mode, stable quality, strong technical force, reasonable price, and high-quality service, we have the ability to provide customers with professional technology and solutions.

Tel: +86 13586040750