screw cap mold

At YUCO Mold, we are committed to providing first-class screw cap mold manufacturing solutions. We undertake both mold manufacturing and screw cap mass production.

screw cap molds from China manufacturer

- The screw cap bottle mold is made of high-quality materials and is durable, ensuring that the bottles produced are of high quality and reducing the cost of frequent mold changes for enterprises.

- The mold design is precise. The screw cap bottle mold has high precision, high accuracy and high consistency, and is able to produce high-quality bottles that meet customer specifications.

- The mold is strong and corrosion-resistant. It can withstand high pressure and high temperature, and is an ideal solution for the production of beverage bottles.

- The screw cap mold has a simple design, convenient operation, easy to disassemble and clean quickly, saving time and reducing labor costs, and is suitable for enterprises of all sizes.

screw cap mold specifications

| Category | Specification | Details |

|---|---|---|

| Mold Construction | Material | H13 Tool Steel, P20, S136, Stainless Steel (customizable based on requirements) |

| Mold Type | Cold Runner, Hot Runner, Semi-Hot Runner | |

| Number of Cavities | 4, 8, 16, 32 (custom configurations available) | |

| Design Software | CAD/CAM integrated design using advanced software for precision and customization | |

| Precision & Quality | Tolerance | ±0.005mm to ±0.01mm ensuring high precision |

| Surface Finish | Mirror Polished, Textured Finishes, Customized Surface Treatments | |

| Dimensional Accuracy | Ensures dimensions meet exact specifications for optimal cap fitting and performance | |

| Performance | Injection System Compatibility | Compatible with hydraulic and all-electric injection molding machines |

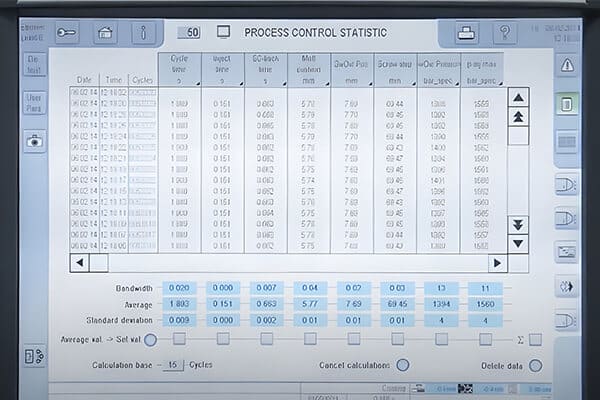

| Cycle Time Optimization | Designed for reduced cycle times (e.g., <10 seconds per cycle) enhancing production efficiency | |

| Cooling System | High-efficiency conformal cooling channels or traditional cooling based on design requirements | |

| Ejection System | Plunger, Sleeve, Brush Type ejection systems for smooth cap removal | |

| Customization | Cap Profiles | Custom cap profiles, sizes, and thread designs tailored to client specifications |

| Logo Engraving | Integrated logo and branding options on caps | |

| Gate Types | Submarine, Pin, Edge Gates adaptable to specific molding needs | |

| Durability | Heat Treatment | Hardened to HRC 50 or higher for extended mold life |

| Longevity | Engineered for over 500,000 injection cycles without degradation | |

| Maintenance | Ease of Maintenance | Easy access for maintenance with interchangeable inserts and modular components |

| Serviceability | On-site technical support and training provided for efficient mold upkeep | |

| Compliance & Standards | Quality Certifications | ISO 9001 certified, complies with international quality and safety standards |

| Regulatory Compliance | Meets FDA, CE, and other relevant industry regulations for food-grade and safety requirements | |

| Support & Services | Technical Support | 24/7 technical assistance, on-site training sessions, and comprehensive after-sales support |

| Lead Time | Fast production lead times (typically 4-6 weeks) without compromising quality | |

| OEM Capabilities | Fully compatible with major injection molding machines, supporting large-scale production runs | |

| Advanced Features | Automation Integration | Compatible with automated systems for streamlined production processes |

| Smart Mold Technology | Equipped with sensors and IoT capabilities for real-time monitoring and predictive maintenance | |

| Sustainability Features | Environmentally friendly materials and energy-efficient design elements |

China plastic cap mold manufacturer

screw cap molding processing

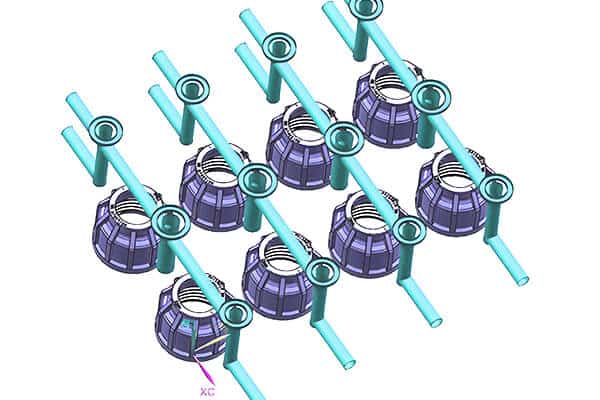

Screw cap molds are high-quality injection molds designed for manufacturing bottle caps of various sizes and shapes. Injection molds usually consist of two parts. The basic structure includes a core and a cavity. The core forms the inner surface of the bottle cap, while the cavity forms the outer surface.

The main application scenario of plastic injection screw cap molds is plastic product processing plants, which are used to mass produce various plastic bottle caps. The application of these molds has greatly improved production efficiency, reduced production costs, and ensured product quality.

01 Understanding Customer Needs

At YUCO MOLD, we always start by learning and understanding all the details of the bottle cap products you produce, and then determine the best production process and equipment.

02 Meeting

YUCO needs to carefully evaluate numerous factors. Different cap mold designs require different materials to ensure optimal durability and shape. Complex shapes and delicate elements may require complex molding methods and precision engineering. Consider cap tolerances and functional production capabilities. In addition, planned production volumes will also affect decisions.

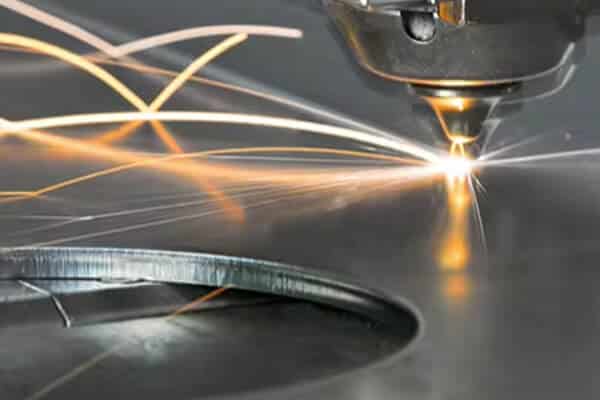

03 mold manufacture

To manufacture these molds, engineers must carefully plan each manufacturing stage to ensure that every detail is consistent with best practices to achieve optimal performance. YUCO has high-precision CNC machining centers, high-precision automated machine tools, advanced equipment and testing instruments.

04 Testing

Each set of molds undergoes strict mold testing before delivery. We can provide experienced teams for installation and testing, standard interchangeable mold components according to customer requirements.

05 technical support

YUCO also has excellent after-sales customer service. English version machine manuals and spare parts will be delivered to customers along with the bottle cap mold. In addition, YUCO will send experienced and skilled engineers to the location where you install the machine and complete the remaining work to ensure that the machine is always available.

Materials used for screw caps

Material selection is a crucial part of the plastic bottle cap mold customization process, affecting the durability, flexibility and chemical resistance of the bottle cap. In addition, depending on the specific application requirements, YUCO MOLD will also select customized materials with special properties such as antistatic or UV resistance. These adjustments ensure that the bottle cap meets the intended use and improves performance.

PP

PET

Nylon

HDPE

Elastomers

Why choose YUCO screw cap mold?

In the design and manufacturing process of bottle cap molds, material selection, design rationality of each system, and application of thread demolding technology are key factors to ensure mold performance, life and production efficiency. By optimizing these aspects, high-quality bottle cap production can be achieved to meet the needs of different batches and functions.

Key points for screw cap product design

The first thing to consider is the size, shape and quantity of the bottle cap, as well as compatibility with different containers. YUCO can modify the mold size to accommodate a variety of container calibers, achieving a tight fit and leakproof. In addition, adjustable bottle caps can be made as needed to accommodate different container sizes for multi-packs or retail products.

The color and surface treatment of the custom bottle cap mold will affect the visual appeal and tactile experience of the bottle cap. You can choose a color that represents your brand or enhance the product appeal through aesthetic design. A variety of surface treatments, including matte, glossy and textured surfaces, can make retail products stand out on the shelf and meet industry and consumer preferences.

In addition to aesthetics, custom screw cap molds can also integrate various functional features. For example, child-resistant or tamper-proof closures can protect pharmaceuticals and hazardous materials; venting and pouring spouts are designed for applications that require controlled liquid dispensing. These functional customizations improve product safety, convenience and usability to meet the needs of different industries.

Materials used in molds

Manufacturing bottle cap molds requires a variety of materials to choose from, depending on the intended use and the type of product being produced. The choice of material affects the performance, life, and cost-effectiveness of the mold, so manufacturers can customize bottle cap molds according to specific needs. Common materials include steel, aluminum, and other alloys, each with different properties:

- Steel: High strength, good wear resistance, suitable for mass production.

- nickel-plated steel: In industries such as automotive or pharmaceuticals, bottle caps may be exposed to extreme temperatures or corrosive substances. Using this material can enhance oxidation and wear resistance, extend mold life, and reduce replacement frequency.

- Aluminum: Lightweight, easy to process, suitable for small batch applications and prototyping.

- Composite materials: As technology develops, they are gradually used to improve molding capabilities and reduce environmental impact.

For steel cavities and cores, YUCO uses imported 1.2316 stainless steel, which has high hardness, corrosion resistance, fine polishing, high mold precision, and excellent quality.

In addition, we also process the cavity and core. For example, heat treatment and machining to extend the service life. The neck screw is nitrided and, with good operation, guarantees more than 2 million injection cycles.

Mold system design

Mold design is critical to the final product of the bottle cap. Key factors include:

- Gate: Common forms of gates include side gate entry and top hot runner entry. The nozzle needle is driven by pneumatics, which can open and close at high speed at the same time, and can effectively control the injection hole of each cavity. It has reliable sealing function, smooth movement, low thermal expansion rate and long service life, while saving electricity.

- Hot runner: The hot runner system designed and manufactured by ourselves can achieve ideal and rapid heating effect, so that the cavity has a lower injection pressure and reduces the wear of mold parts.

- Heating system: A dual heating system is adopted with independent temperature control. The heating rod is used to heat the mold main board, and the small heater continuously provides the required heating temperature for the cavity and nozzle.

- Cooling system: Each part such as the core, cavity, valve, etc. is equipped with an independent cooling system to ensure uniform cooling of the mold, reduce product deformation, and shorten the injection cycle. Reasonable water channel diameter and uniform layout are the key.

In addition, multi-cavity molds improve production efficiency. Molding accuracy affects the functionality, aesthetics and fit of the bottle cap, especially for branded products.

Production volume and mold life

Considering the overall production goals and expected output is crucial to choosing the right mold. For large-scale production, sturdy steel molds are more suitable because of their durability and long service life; while for small-scale production, softer aluminum molds are more practical. This consideration directly affects cost-effectiveness and long-term production stability, avoiding frequent mold replacement.

Mold Cost

Cost analysis is a key factor in selecting a plastic bottle cap mold. You need to consider the cost of the mold itself as well as the expenses associated with maintenance and operation. Steel molds have a higher initial cost but are more economical in high-volume production; aluminum molds are less expensive and are suitable for small batches or prototypes. These costs need to be weighed against the expected usage of bottle caps to ensure the best overall financial and operational efficiency.

YUCO, your trusted Chinese screw cap mold manufacturer

YUCO provides more than 100 sets of bottle cap molds every year, which have been recognized worldwide. According to customer feedback, these machines run smoothly, steadily and perfectly. It not only helps customers gain business through high-quality bottle cap production, but also adds charm to the production site through its exquisite appearance.

Our mold manufacturing department can manufacture single-cavity or multi-cavity molds of different sizes. According to your product data, our engineers can provide you with a feasible solution with low price and high quality. The following demonstrates our manufacturing capabilities:

- Maximum mold size 2500mm×2000mm×1500mm

- Highest machining accuracy: ±0.005mm

- Highest injection accuracy: ±0.03mm

The delivery time for each mold is 25-45 days, depending on its complexity. If you have any mold development inquiries, please send us your inquiries along with 2D and 3D drawings or samples, molding requirements are also accepted.

Tel: +86 13586040750