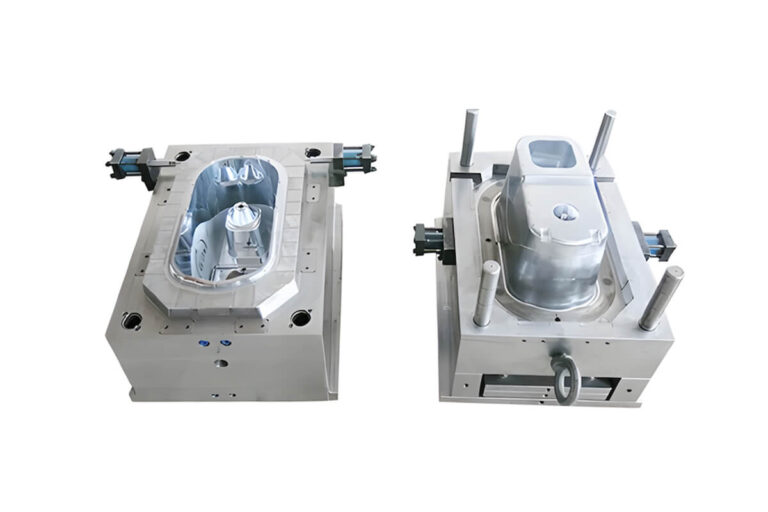

How to make a good bucket mold

An excellent mold is not only a tool, but also a blueprint for success in the highly competitive field of plastic manufacturing. In this blog, we will show you how to make a good bucket mold, the entire process from design to manufacturing, and how to optimize it.

Key elements of bucket mold design

The design of a bucket mold requires careful engineering of several key features that together ensure the highest quality and efficiency when the bucket is formed. Let us analyze the key elements of bucket mold design to ensure efficient output and stable product quality.

Selection of mold steel

The choice of bucket mold steel has a great impact on its service life and functionality. Common materials include:

- P20 steel: Widely used for its excellent workability, durability and corrosion resistance, it is ideal for high-volume production and is relatively cheap.

- 718H Steel: Known for its excellent polish ability and enhanced thermal stability, 718H steel is often the material of choice for high-quality surface finishing. The price is a bit more expensive than P20.

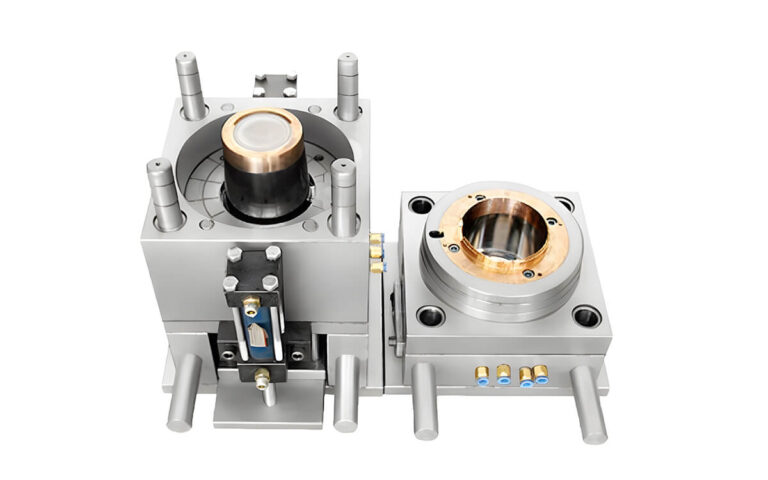

- Beryllium Copper (BeCu): Because beryllium copper has excellent thermal conductivity, it can significantly reduce cooling time and improve overall cycle time. Therefore, beryllium copper is often added to key areas of bucket molds, such as the top of the core and the neck of the cavity. But beryllium copper is relatively expensive.

| Material | Main Features | Applications | Relative Cost |

|---|---|---|---|

| P20 Steel | Excellent machinability, durability, and corrosion resistance | Ideal for high volume production | Relatively inexpensive |

| 718H Steel | Excellent polishability and enhanced thermal stability | Preferred for high-quality surface finishing | More expensive than P20 |

| Beryllium Copper (BeCu) | Outstanding thermal conductivity | Used in critical areas of molds to reduce cooling times and improve cycle times | Relatively expensive |

Choosing the right steel is fundamental to balancing mold cost, productivity and durability.

Thickness of pouring chamber walls

Uniformity of wall thickness is critical. Incorrect thickness can cause uneven cooling, which can affect the flow of the plastic during the molding process.

A well-calibrated thickness ensures that the plastic cures uniformly, avoiding defects such as warping or uneven surface texture.

Runner systems

Choosing the right runner system, whether cold or hot, is critical to controlling the path and flow of molten plastic into the mold cavity. A well-designed runner system optimizes the use of materials and significantly reduces production cycle time and plastic scrap.

Cooling system

The cooling system in the bucket mold is critical to controlling the temperature throughout the molding process. An optimal cooling system ensures even heat distribution, which is critical to maintaining consistent material flow.

Poor cooling will lead to different shrinkage rates in different parts of the bucket, resulting in defects such as deformation or inaccurate dimensions.

Ejector systems

The ejection system must be designed to reliably eject the hopper from the mold after the plastic has cooled and solidified. An effective ejection system prevents damage to finished buckets and ensures smooth operation during tight production cycles.

Location and type of sprue

The gate is where plastic enters the mold cavity. The location and style of the gate play a vital role in the quality of the finished bucket. Proper gate location ensures optimal flow of plastic to all parts of the mold, minimizing stress and potential weak spots in the bucket. Gate types (such as edge gates, tab gates, or subsea gates) also affect the appearance and strength of the final product.

By carefully considering these factors, bucket mold designers can greatly improve the manufacturing process. YUCO MOLD provides design precision and innovative solutions for making perfect bucket molds.

Processing of bucket molds

The accuracy and efficiency of bucket mold processing directly affect the quality and functionality of the final product. Here we will look at the main machining technologies and discuss the specific technical points that are critical to high-quality bucket mold manufacturing.

Processing technology of bucket mold

CNC machining

Computer Numerical Control (CNC) machining is the cornerstone of mold manufacturing due to its precision and automation. CNC machines use computer control and machine tools to remove layers of material from a blank part, achieving the high precision and consistency required for complex mold designs.

CNC lathes

For cylindrical parts in drum molds, CNC lathes are indispensable.CNC lathes offer unparalleled precision in the forming and finishing of parts that require rotational symmetry, ensuring that all parts fit together seamlessly with minimal tolerances and high surface integrity.

Electrical Discharge Machining (EDM)

Electrical discharge machining is particularly important for manufacturing complex mold features or detailed geometries that are difficult to achieve with traditional machining methods. This process is critical to creating fine, detailed features in the hardened steel, making it ideal for complex bucket mold designs.

Key points of bucket mold processing technology

- Accuracy of processing equipment: The accuracy of processing equipment determines the tolerance level of the mold and affects the consistency of product dimensions. High-precision CNC and EDM machines are critical to achieving the tight tolerances required for quality molds.

- Perfect cooling circulation system: A well-designed cooling circulation system is crucial. The balance of the water circulation affects the fluidity of the molten plastic and the surface thickness of the final product. Typically, varying water flow temperatures can cause wall thickness tolerances to fluctuate by up to 0.05 mm, requiring careful control during the mold design and manufacturing stages.

YUCO MOLD significantly improves the accuracy and quality of drum molds by focusing on these key technical points during bucket mold processing.

Bucket mold surface treatment

Polishing

Polishing is a key step in mold surface treatment. It is mainly used to remove any flaws, rough edges or small defects that may be left during the processing to make the surface smoother. A well-polished mold surface not only facilitates the release of the final product from the mold, but also improves the appearance of the mold.

Heat treatment

Heat treatment can improve the mechanical properties of mold steel, such as toughness and wear resistance. Proper heat treatment ensures that the mold can withstand repeated cycles of high pressure and temperature without deformation or failure.

Protective layer

Applying a protective coating to your mold is another effective way to improve the performance and life of your mold. Coatings help protect the underlying metal from oxidation, wear and corrosion, especially when processing abrasive or corrosive plastics.

Properly prepared surfaces ensure that drum molds meet or exceed their expected service life and maintain high-quality production without the need for frequent downtime for maintenance or repairs.

Bucket mold testing and adjustment

The main purpose of bucket mold testing and adjustment is to identify and correct inconsistencies with the original design specifications, thereby improving production efficiency and quality.

- Trial molding: Before any actual material is introduced, a trial run (testing without production material (usually plastic)) is often performed to ensure that the mold will open, close, and eject the part correctly.

- Material testing: The actual material required for the mold is then used. This step is crucial to analyze the filling, cooling and ejection stages of the injection molding process.

- Mechanical adjustments: If mold parts do not align perfectly or eject smoothly, mechanical adjustments may be needed. This may include adjusting the ejector pin, adjusting the mold opening/closing speed, or adjusting the clamping pressure.

in conclusion

In short, making a high-quality bucket mold requires a comprehensive understanding and meticulous attitude from design to final testing.

At YUCO MOLD, we specialize in designing and manufacturing high-quality bucket molds, customized for you to increase production efficiency and precision. With our expertise in bucket mold design and unparalleled commitment to quality, we ensure unparalleled service and product advantages.

Don’t settle for less – upgrade your bucket production with YUCO’s expertise. Contact us today to discuss how our state-of-the-art bucket molds can help you achieve perfection in every buckets!

FAQs

How to maintain the bucket mold?

In order to ensure the service life and easy maintenance of the mold, the mold surface must be heat treated and chromium plated to reduce wear. Regular maintenance should include cleaning, lubricating and inspecting for any signs of damage or wear. Regular adjustment and calibration of molds is also critical to maintaining the quality of the buckets produced.

What are challenges in the bucket mold manufacturing process?

Common challenges include managing plastic shrinkage during cooling, which can lead to defects in the final product. This can be solved by performing accurate simulations during the design phase and adjusting processing parameters such as temperature and injection speed during production. Another challenge is incorrect ejection of the bucket, which can be mitigated with a well-designed ejection system that distributes force evenly across the surface of the bucket.