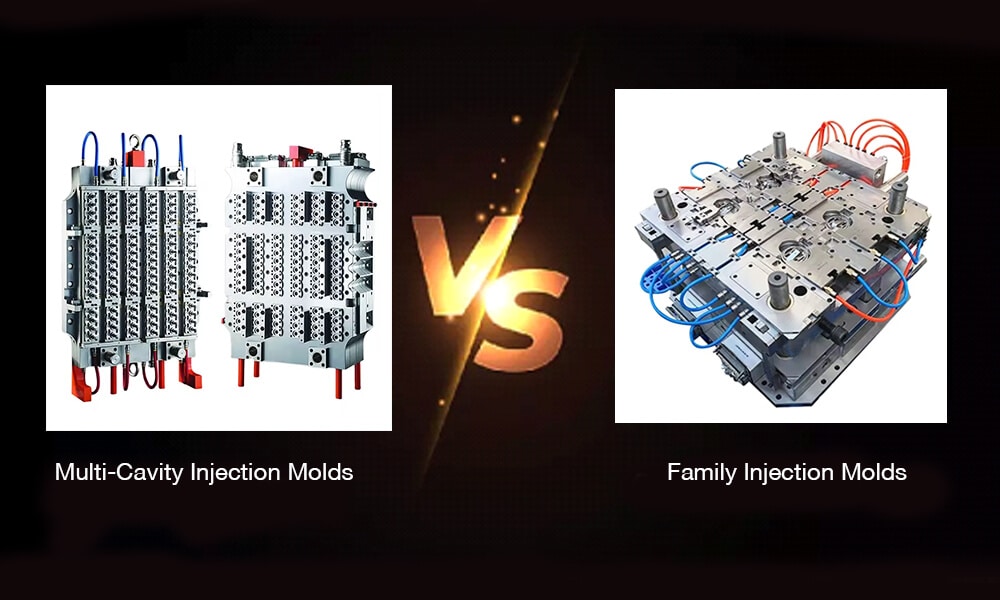

multi-cavity injection molds vs. family injection molds

Plastic injection molding is a popular production technique for making plastic parts. The technology uses engineered mold design, heat and pressure to mold plastic pellets into the desired shape. It provides options for both small—and large-scale manufacturing.

Two popular and standard methods for increasing efficiency and productivity in an injection molding setup are multi-cavity and family mold. Each technology brings its own unique advantages to the manufacturing process.

In this comprehensive comparison, YUCOMOLD explore the details of multi-cavity and family injection molds, where and how they are used, and the important factors you should consider when selecting them for a specific application.

Before discussing the details of the multi-cavity injection molds vs. family injection molds debate, let’s briefly examine what they are.

Multi-cavity molds

As the name suggests, multi-cavity molds consist of a specific mold design that contains multiple cavities of the same shape and size. Each cavity houses, forms and produces the same part.

Unlike single-cavity molds, which can only produce one part per cycle, multi-cavity molds can produce multiple parts simultaneously in a single injection molding cycle due to their numerous identical cavities. As a result, output is significantly increased, and production efficiency is increased, making it possible to produce many parts quickly.

Advantages of multi-cavity molds

Compared to alternative methods, multi-cavity molds offer several benefits. Here are a few important ones:

- Shorter cycle time

- Low cost per part

- Continuous part quality, uniformity and consistency

- Optimization of space and equipment

- Easy inventory management

- Better process control

- Flexibility in part design

Disadvantages of multi-cavity molds

While relying on a multi-cavity mold has several advantages, this process’s limitations are equally significant.

- Increased mold complexity and cost compared to single-cavity molds. Therefore not economically feasible for smaller production runs.

- Maintenance and repair challenges.

- Manufacturing feasibility for certain parts.

- inflexibility when producing different parts simultaneously.

Important design considerations for multi-cavity molds

Below are some of the most crucial factors for manufacturers using multi-cavity molds, in addition to general mold development considerations.

- Cavity balance: Adequate cavity balance must be achieved to ensure continuous filling, cooling, and discharge during the process.

- Runner system design: Designing an efficient runner system that allows adequate material flow to each cavity in a multi-cavity mold is essential.

- Cooling system: Another important factor is an efficient cooling system to ensure uniform cooling in all cavities. Adequate cooling helps prevent part warpage, reduces cycle time, and improves productivity.

- Mold material and construction: Finally, construction and material selection ensure that the mold performs as expected. To ensure the mold can handle the rigors of high-volume production, consider variables like surface coatings, mold maintenance requirements, and mold steel selection.

Family molds

Unlike multi-cavity molds, family molds do not create identical parts. Instead, this unique design allows for the simultaneous production of different but complementary parts that are often assembled together to form a complete product.

Advantages of family molds

- Cost-effective for small to medium-volume production, making them an excellent choice for businesses that require a variety of components without excessive quantities.

- Better performance. Production is significantly faster than using separate molds for different parts

- Better part compatibility. Easily adaptable to production runs that require complex assemblies or parts to be assembled together after molding

Disadvantages of family molds

As with the advantages, there are some disadvantages to relying on family molds.

- Requiring greater precision and sophistication in mold design and machining, which may translate accordingly into higher upfront costs.

- Higher risk of defects. Because different parts within the mold may require different cooling times and treatments, potential inconsistencies can occur.

Important design considerations for family molds

- Partial compatibility and interactions: Consider the compatibility and interaction between the different parts in the family mold. Calculate possible part variations and design molds to accommodate various sizes, shapes, and features.

- mold flexibility: Design family molds with flexibility to accommodate individual part design changes or iterations. Use interchangeable inserts or modular mold components to simplify part variations and allow easy mold maintenance and repair.

- Mold separation and extrusion: Pay close attention to mold separation and extrusion procedures to ensure efficient and reliable extrusion of all parts. Design proper parting lines, slides, and lifters to facilitate easy part release without risking component damage.

- Parting line considerations: To reduce mismatches and potential cosmetic defects, carefully design the parting line since multiple parts have different geometries. Consider the part design and material flow to minimize the effect on part quality and optimize parting line placement.

- Runner system design: Runners must be carefully designed to ensure even flow to all cavities. Imbalance creates undesirable stress points that compromise the aesthetics and structural integrity of the final product.

multi-cavity molds vs. family molds

Choosing between multi-cavity molds and family molds requires understanding each mold. Every manufacturing decision is situation-specific and requires a thorough analysis of factors such as quantity, part variations, cost, and required quality.

Production

The selection of the preferred mold depends largely on the required production volume. Multi-cavity molds are ideal for manufacturer that need to produce individual parts in high volumes. For example, a beverage company that produces millions of identical bottle caps would benefit from using a multi-cavity mold.

But not every plastic product is made up of a single piece. Many of these are complex assemblies that become usable after different types of parts are attached. At this time, family molds have advantages in situations where individual components of a product are produced simultaneously in medium batches. For example, manufacturers of small home appliances such as electric toothbrushes can use family molds to produce different plastic parts of their products simultaneously.

In summary, a multi-cavity mold is the best way to reduce lead time by making multiple parts simultaneously. However, they do not cover the various parts required for complex assembly. Family molds can make many parts at once but can’t make the same amount of identical parts in a single cycle.

Cost considerations

Initial costs are similar for multi-cavity and family molds. However, overall cost decreases as production volume increases. Since they can make several copies in a single cycle, multi-cavity molds are economical and can drastically lower the cost per part.

Family molds offer a different cost-saving opportunity. Instead of investing in separate molds for other parts, it is possible to work with one. Although design and tooling costs may be higher, when spread over a variety of different parts, the unit manufacturing cost can be quite favorable.

Design complexity and flexibility

Multi-cavity injection molds require more straightforward mold than family molds. The cavities are matched, and identical parts can quickly be produced, streamlining the production cycle and the tooling process.

On the other hand, family molds require more tooling and considerations to ensure effective production, making them more complex due to their ability to accommodate multiple designs.

The characteristics are reversed when it comes to flexibility. Because multi-cavity molds have identical cavities, changing designs or parts can be difficult and time-consuming. However, family molds can significantly reduce downtime because changeovers between parts are more accessible and faster due to the differences in their cavities.

quality and consistency

Multi-cavity molds excel in uniformity and consistency because they are designed to produce identical parts. The identical mold cavity offer better filling and cooling properties that can reduce variations and defects in manufactured parts. Industries where accuracy is critical, such as aerospace or medical equipment, may find multi-cavity molds useful.

On the other hand, family injection molds are quite challenging to maintain in terms of consistency and quality. family molds have different cavities, which present a slightly increased risk of defects and require more careful handling.

Variations in component design may vary regarding cooling requirements and fill characteristics. However, effective process control and optimization can reduce and eliminate these problems.

in conclusion

When starting a manufacturing project, choosing the right mold type (multi-cavity mold or family mold) is crucial. These choices not only directly impact production costs, but also the quality, uniformity and efficiency of the manufacturing process. While multi-cavity molds excel at high-volume production of single parts, family molds have proven ideal for producing multiple parts of the same product simultaneously.

Here’s a quick summary in tabular form for easier comparison:

| Criteria | Multi-cavity Moulds | Family Moulds |

|---|---|---|

| Production | High | Moderate |

| Part Variation | Low | High |

| Cost | High (with volume) | Moderate |

| Quality | High | Medium |

This decision can be difficult, but we can provide expert guidance based on your unique project requirements. YUCO wants you to have all the information you need to help you make a decision.

As a leading plastic mold manufacturer in China, YUCOMOLD not only has rich industry experience and diversified mold selections, but also provides comprehensive mold design services, whether it is multi-cavity mold or family mold.

When you work with us, you can expect high-quality tooling and molding solutions, timely delivery, competitive pricing, and unparalleled customer service. So whether your product requires the consistency of a multi-cavity mold or the versatility of a family mold, our team can evaluate your needs and recommend the most appropriate product.

Please feel free to contact us.

FAQs

Can multi-cavity molds accommodate different part designs?

Multi-cavity molds are typically used to produce identical or very similar parts. Although variations can occur within the same mold, significant differences in part geometry or size may require separate molds.

How do you ensure quality control with multi-cavity molds?

Quality control measures such as regular part inspections, monitoring process parameters such as temperature and pressure, and mold maintenance are essential. Additionally, automation and robotics for part handling can increase consistency and quality.

Is there a limit to the number of cavities in a multi-cavity mold?

The number of cavities depends on part size, complexity, and material properties. Although there is no fixed limit, practical considerations such as mold size, cooling efficiency, and injection molding machine capacity can be constraints.

What are some considerations for maintenance with family molds?

Maintenance for family molds includes regular cleaning, inspection for wear and damage, and address of any problems that may affect part quality or mold performance. Proper storage and handling of the mold are also essential to prolong its life.

Can family molds produce parts with different surface finishes or textures?

Yes, family molds can produce parts with different levels of finish or texture. This can be achieved by adding different cavity inserts or surface treatments to the same mold.