injection molding molds 101

YUCO will help you gain a comprehensive understanding of injection molds, covering everything from basic design principles to advanced manufacturing techniques.

Understanding the components of an injection mold is critical for anyone involved in the design or manufacture of plastic parts. Each component plays a specific role in the molding process, and its proper design and integration determines the success of the final product.

Cores and cavities

The core and cavity are the main components of the mold and form the heart of any injection mold, creating the negative space that determines the geometry of the part. The cavity forms the outer surface of the molded part, while the core shapes the internal features. These components must be manufactured to extremely tight tolerances, typically within ±0.001 inches, to ensure consistent part quality.

In most two-plate mold designs, the core typically moves during the mold operation, while the cavity remains stationary. Both components are subjected to tremendous thermal and mechanical stresses during production, so careful material selection and heat treatment are required to maintain dimensional stability over millions of cycles.

Runner systems

The runner system delivers molten plastic from the injection molding machine’s nozzle to the part cavity. Cold runner systems use channels machined into the mold to fill with plastic with each cycle.

Hot runner systems use heated manifolds and nozzles to keep the plastic molten throughout the runner. This eliminates runner waste and reduces cycle time, but requires a more complex mold design and a higher initial investment. Hot runners are particularly useful for high-volume production and when using expensive engineering plastics.

Ejector systems

Once the molded part has cooled sufficiently, it must be removed from the mold. Ejector systems accomplish this through a variety of mechanisms, including ejector pins, ejector sleeves, stripper plates, and air ejectors. Ejector systems must apply force evenly to prevent deformation or damage during removal.

Ejector pins are the most common method, strategically positioned to push the part away from the core while minimizing visible marks on the finished product. The timing and force of the ejection must be carefully controlled to ensure consistent removal of the part without stress cracks or dimensional changes.

Cooling systems

Efficient cooling is critical to maintaining consistent part quality and reducing cycle times. Cooling channels are typically drilled channels that circulate water or oil to remove heat from the molten plastic. The design and layout of these channels can significantly affect cooling uniformity and cycle efficiency.

Traditional straight-bore cooling channels are being replaced by conformal cooling. Systems that more closely follow part geometry. These advanced cooling systems are often manufactured using additive manufacturing techniques and can reduce cooling times by 20-40% while improving part quality.

Venting systems

As molten plastic fills the mold cavity, air must be vented to prevent defects such as burn marks, undershot or bubbles. Venting systems provide a controlled path for air to escape while preventing plastic from flowing out of the mold.

Vents are typically very shallow grooves, typically 0.0005 to 0.002 inches deep, located at the parting line or other critical locations. Proper venting is critical to filling complex geometries and achieving consistent part quality, especially for parts with thick sections or intricate details.

Parting lines and cutoff surfaces

The parting line defines where the mold separates to allow for part removal. This line must be carefully positioned to minimize its visual impact on the finished part while ensuring proper mold operation. The cutoff surface is a critical sealing area that prevents plastic from flashing between mold components.

These surfaces require precision machining and regular maintenance to prevent flash from forming, which can cause part quality issues and make ejection difficult. The design of the parting line also affects mold complexity and manufacturing costs.

Mold materials and manufacturing

Choosing the right injection mold material and manufacturing method directly affects the performance, life, and cost-effectiveness of the mold. Understanding these factors can help make informed decisions that optimize the balance between initial investment and long-term productivity.

- Mold steel is the most widely used mold material, with excellent hardness, wear resistance, and thermal properties. P20 steel is often used for prototypes and low-volume molds due to its easy processing and moderate price. For high-volume production, H13mold steel is an ideal choice for demanding applications.

- Stainless steels such as 420SS have excellent corrosion resistance and can be used to mold PVC, POM, and other corrosive materials. Premium mold steels such as S7 and A2 have excellent wear resistance and are suitable for abrasive materials or very high production volumes.

- Aluminum molds have advantages for prototype molds and low-volume production. Aluminum can be processed faster than steel, which reduces the lead time and cost of the initial mold. However, aluminum has a lower hardness, which limits its durability.

- Beryllium copper alloys have excellent thermal conductivity and are well suited for applications that require rapid heat transfer. These materials are often used as inserts in critical cooling areas or for molding thick-walled parts that require enhanced heat dissipation.

Traditional machining methods

Traditional machining remains the foundation of mold manufacturing, utilizing milling, lathe, grinder, and drill press equipment to create mold components. Computer numerical control (CNC) machining has revolutionized mold manufacturing by enabling precise, repeatable machining operations with minimal human intervention.

Multi-axis CNC machining centers can produce complex geometries in a single clamping, reducing processing time and improving accuracy. Advanced tools and cutting strategies significantly reduce machining time while improving surface finish.

Advanced Manufacturing Technologies

Electrical discharge machining (EDM) can cut precise contours in hardened steel, achieving complex internal geometries that are not possible with conventional machining.

High-speed machining uses specialized spindles and tools to achieve extremely high cutting speeds and feed rates. This technology can reduce machining time by 50-80% compared to conventional methods while achieving excellent surface finish.

Additive manufacturing is becoming a valuable tool in mold making, especially for conformal cooling channels and complex internal features. Metal 3D printing can produce mold inserts with internal features.

Surface treatments and coatings

Surface treatments improve mold performance and life. Nitriding creates a hard, wear-resistant surface layer while maintaining core toughness. Chrome plating provides excellent corrosion resistance and low friction, which improves part release. Advanced coatings such as titanium nitride (TiN) and diamond-like carbon (DLC) offer exceptional hardness and wear resistance. These coatings can significantly extend mold life when molding abrasive or corrosive materials.

Mold design considerations

Successful mold design requires balancing multiple competing factors, including part quality, manufacturing cost, production efficiency, and mold life. Understanding key design principles can help you design molds that consistently produce high-quality parts and minimize manufacturing challenges.

Draft

Draft is a slight taper applied to vertical surfaces to ease ejection of the part from the mold. Insufficient draft can cause the part to stick in the mold, resulting in ejection problems, part deformation, or mold damage. Typical draft angles range from 0.5 to 3 degrees, depending on part material, surface texture, and draft depth.

Textured surfaces require additional draft to prevent resistance during ejection. Deep ribs or bosses may require up to 5 degrees of draft to ensure reliable ejection. Draft angle must be balanced with part design requirements and aesthetic considerations.

Shrinkage Compensation

All plastic materials shrink as they cool from the molten state to room temperature. Mold designers must compensate for this shrinkage by making the mold cavity larger than the desired final part size. Shrinkage varies greatly from material to material and is affected by processing conditions, part geometry, and fiber orientation in reinforced plastics.

Accurate shrinkage compensation requires knowledge of specific material properties and processing conditions. Semi-crystalline materials such as polyethylene and polypropylene typically shrink more than non-crystalline materials such as polystyrene or ABS.

Gating design

The gate is the point where molten plastic enters the part cavity, and its location and design can significantly affect part quality. The gate must be located to ensure complete filling of the cavity while minimizing flow-related defects such as weld lines, sink marks, and warpage.

Common gate designs include main gates, edge gates, tab gates, and pin gates. Each type offers specific advantages depending on part geometry and quality requirements. Gate location affects material flow patterns, cooling behavior, and the visibility of gate marks on the finished part.

Managing weld lines

Weld lines form when different flow fronts meet during cavity filling. These lines can create weak spots and visible surface defects on the part. Mold designers must use computer simulation to predict flow patterns and position gates to control weld line locations or eliminate them entirely.

Flow pattern optimization involves balancing fill rates across multiple gates, adjusting gate sizes, and modifying part geometry to promote smooth material flow. Advanced simulation software enables designers to visualize fill behavior and optimize gate locations before the mold is built.

Undercuts and sideways motion

Undercuts are features that prevent a part from being ejected straight from the mold. These features require sideways motion, also called a slide or lifter, that moves perpendicular to the main mold opening direction. Sideways motion adds complexity and cost to the mold, but can produce parts with complex geometries.

The design of the sideways motion system requires careful consideration of the drive method, wear surfaces, and timing. Cam-driven slides are most common, but hydraulic or pneumatic systems may be required for large or heavy sideways motion.

Learn how we can help you overcome your injection mold challenges.

Types of injection molding molds

The diversity of plastic parts requires a variety of molds, each optimized for specific applications, production requirements, and economic factors. Understanding the different mold types will help you choose the right mold for each application.

Two-plate molds

Two-plate molds are the simplest and most common mold configuration and consist of two main plates separated along a single parting line. The cavity is machined on one plate and the core is machined on the other. This configuration is the least expensive to manufacture and the easiest to operate.

Two-plate molds are ideal for parts that can be ejected in the direction the mold opens and do not require complex gate arrangements. They excel in high-volume production where simplicity and reliability are critical.

Three-plate molds

Three-plate molds add a third plate between the cavity plate and the core plate, creating two parting lines. This configuration allows point gates to be embedded directly into the part, which is beneficial for appearance parts or parts that require flexible gate locations.

The additional plate complexity increases manufacturing costs and cycle time due to the need to open the gates in sequence. However, three-plate molds provide better gate location selection and automatic gate separation, which can improve part quality and reduce secondary operations.

Hot runner molds

Hot runner molds use heated manifolds and nozzles to keep the plastic molten throughout the runner system. This eliminates runner waste and reduces cycle time, making them cost-effective in high-volume production.

Hot runner systems require sophisticated temperature control, which increases the complexity of mold design and maintenance. However, eliminating runner waste and reducing cycle time are often worth the additional investment, especially for expensive engineering plastics.

family molds

Family molds produce multiple different parts in a single cycle, sharing runner systems and machine cycle times. This approach is very cost-effective for parts that are used together in the assembly process or when production volumes are not high enough to warrant separate molds for each part.

Balancing family molds presents unique challenges because different parts may have different wall thicknesses, materials, or cooling requirements. Successful family mold design requires careful analysis of each part’s processing requirements and their compatibility.

Advanced mold technology

Injection molding technology continues to advance beyond the limits of plastic part production. Advanced mold technology enables the production of parts with enhanced functionality, higher quality, and greater design freedom.

Conformal cooling systems

Traditional cooling channels follow a straight path drilled through the mold steel, which often results in uneven cooling, which increases cycle time and causes part quality issues. Conformal cooling systems follow the contours of part geometry, provide more even heat dissipation, and significantly reduce cooling time.

These systems are typically manufactured using additive manufacturing technology, embedding cooling channels directly into the mold insert. Improved cooling uniformity can reduce cycle time by 20-40% while minimizing warpage and improving dimensional consistency.

Gas-assisted injection molding molds

Gas-assisted injection molding introduces pressurized gas into the part during the molding process, creating a hollow structure that reduces material usage and eliminates sink marks. The technology requires specialized mold design, including gas injection points and exhaust systems.

The process is able to produce thick-walled parts, eliminating sink marks, while reducing weight and material consumption. Applications include automotive structural parts, furniture components, and appliance housings, where strength-to-weight ratio is critical.

two-shot & multi-shot molds

Multi-material molding combines different plastics into one part, enabling the production of products with different performance in different applications. The technology requires precision mold systems with multiple injection units and precise timing control.

Common applications include soft-touch handles on tools, flexible seals integrated with rigid housings, and multi-color consumer products. The technology eliminates the need for assembly operations while producing parts with enhanced functionality and appearance.

In-mold labeling and decoration

In-mold labeling (IML) and in-mold decoration (IMD) technologies integrate labels or decorative films into parts during the molding process. This technology requires a precise label positioning system and specialized mold design to accommodate label placement and molding operations.

IML eliminates the need for secondary labeling operations while providing superior durability and appearance compared to direct labeling. This technology is widely used in packaging, automotive interior components, and consumer electronics where durability and appearance are critical.

Industry Applications and Case Studies

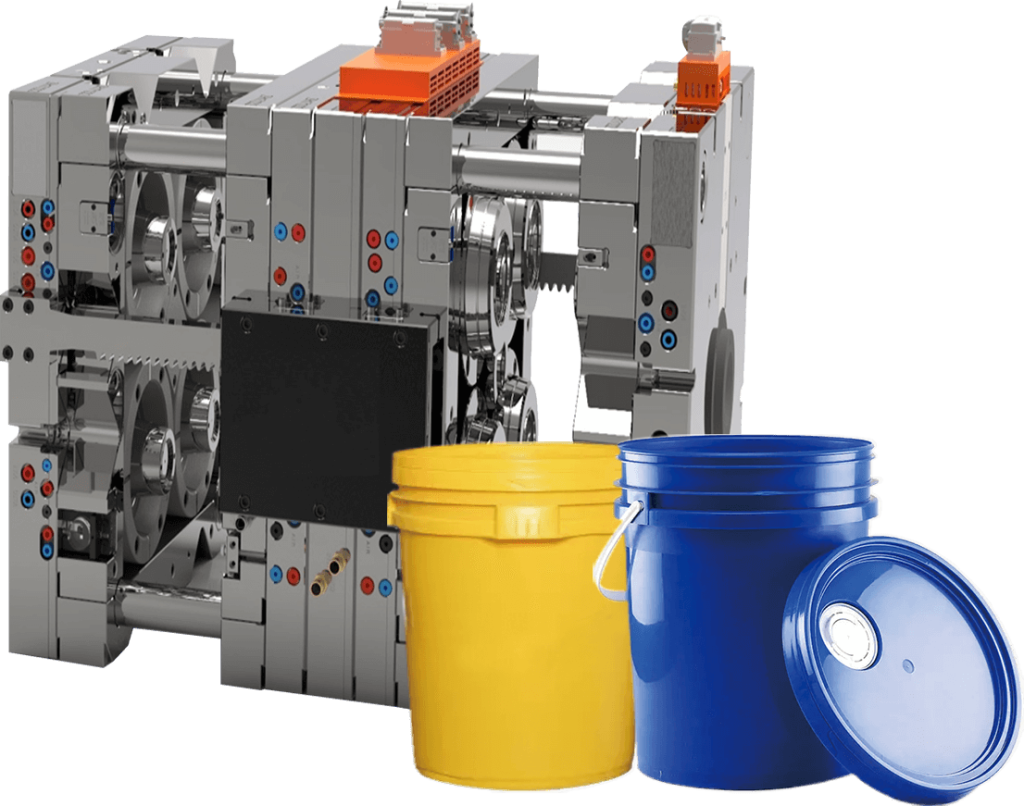

bucket mold

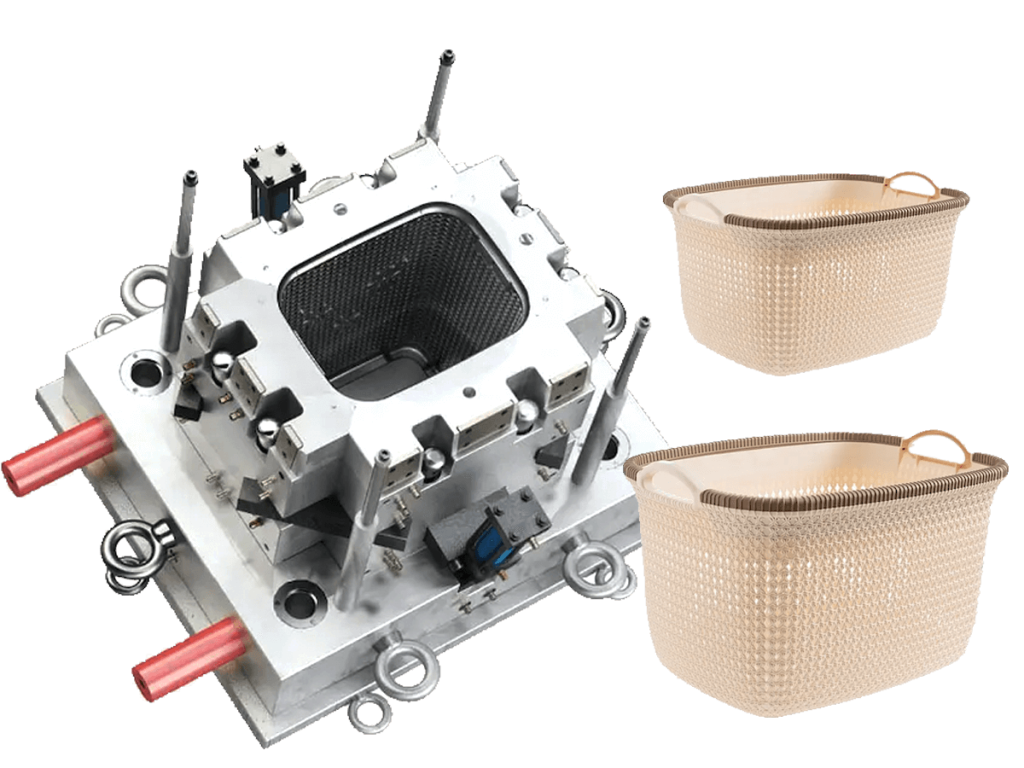

basket mold

Customize high-quality plastic basket molds from our manufacturing facility in China. YUCO's team of experts have years of experience in mold design and manufacturing, combining technology with traditional craftsmanship to deliver a superior product.

They are used in a wide range of applications in daily life, from small baskets suitable for storing office supplies to large baskets suitable for storing toys or clothes. Shapes include rectangles, squares, circles, ovals, etc., depending on the intended use and desired aesthetics. Colors include bright colors for children's rooms, neutral tones for home organization, and even transparent options.

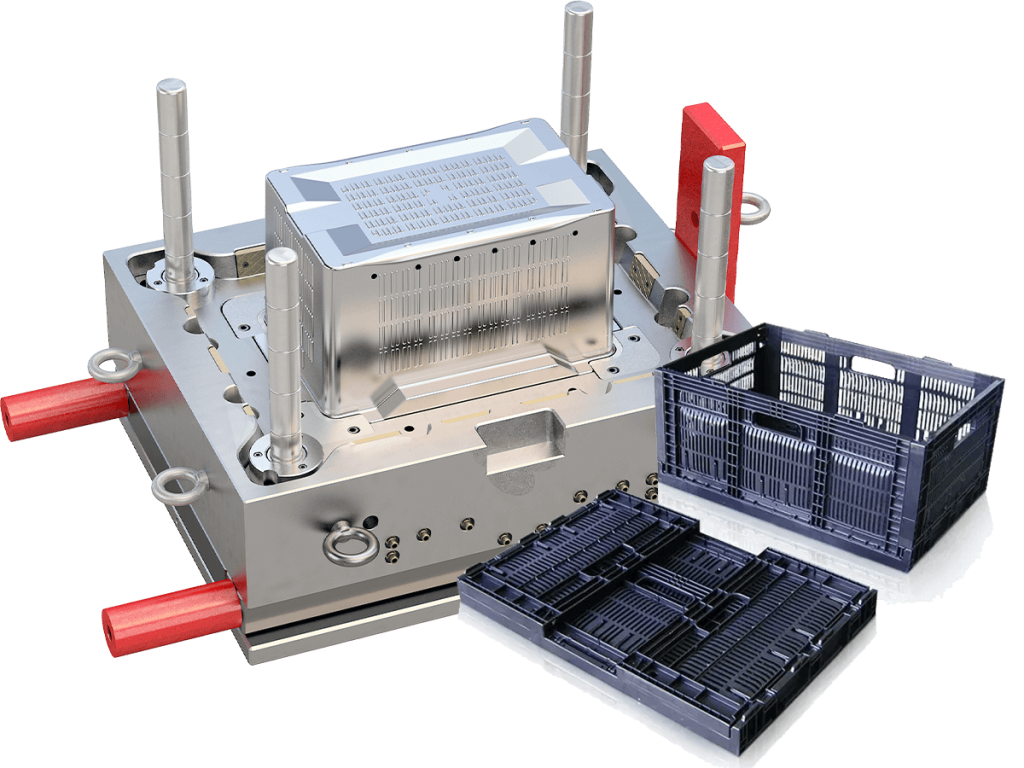

crate mold

Whether you need professional crate mold design and manufacturing or one-stop crate molding services, YUCO MOLD can meet your requirements.

YUCO provides end-to-end services, from initial concept development to final plastic mold production. Besides, our state-of-the-art facilities can handle all aspects of crate production. Whether you need small batch production or large-scale manufacturing, we have the ability and flexibility to meet your needs.

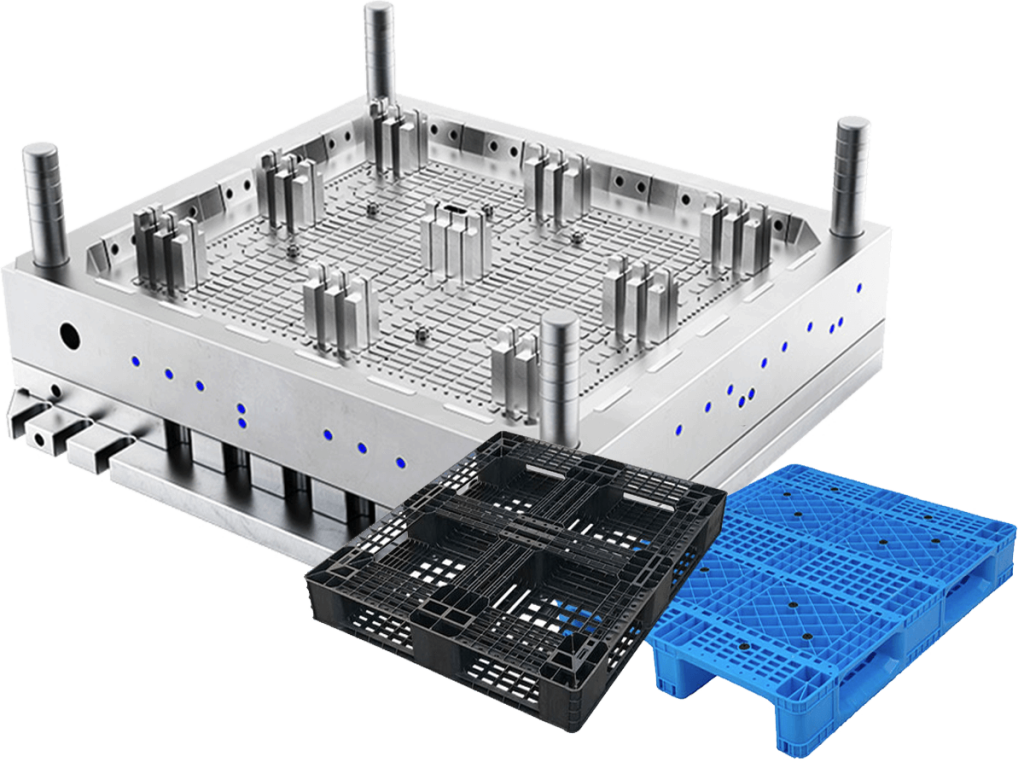

pallet mold

Pallet molds are made in China, and YUCO has in-house capabilities covering the entire mold production process, from design, processing, sampling to mass production. This ensures excellent delivery time, total cost control and consistent product performance.

We can also help you manage the entire production process. The plastic procurement department will purchase high-quality raw materials, while the technical department will select the appropriate plastic formula. According to the plastic pallet mold life requirements and market positioning, we will select the most suitable plastic pallet parameters, structure, etc. Our comprehensive production capacity enables us to deliver plastic pallets quickly, at competitive prices and with guaranteed quality.

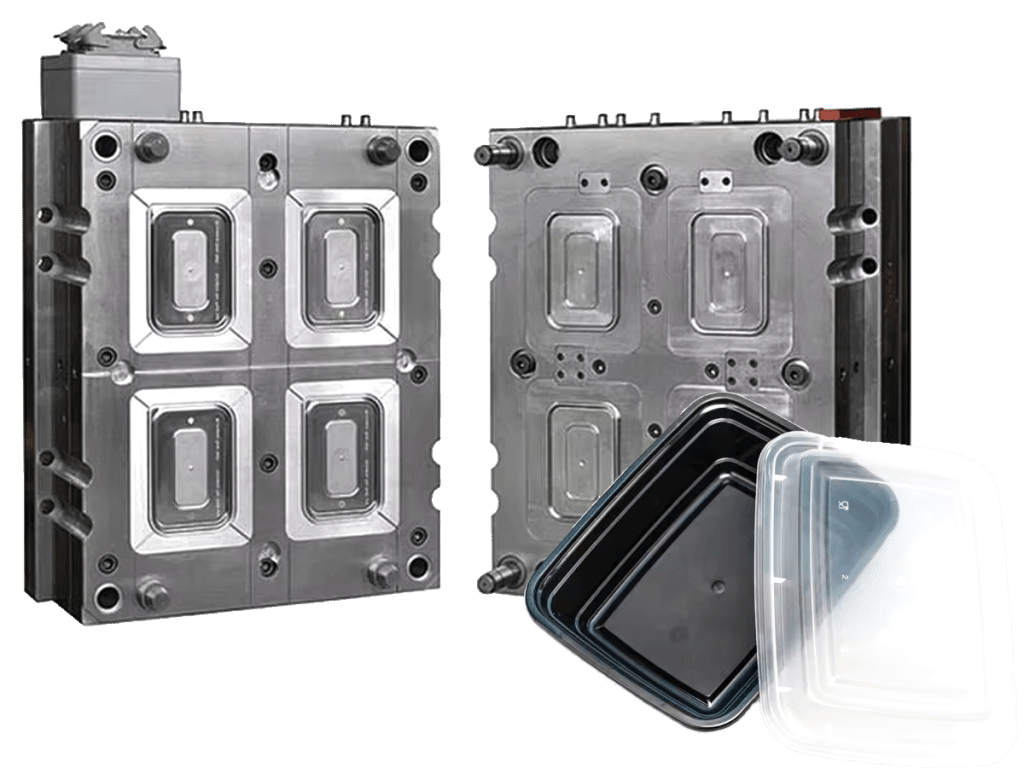

food container mold

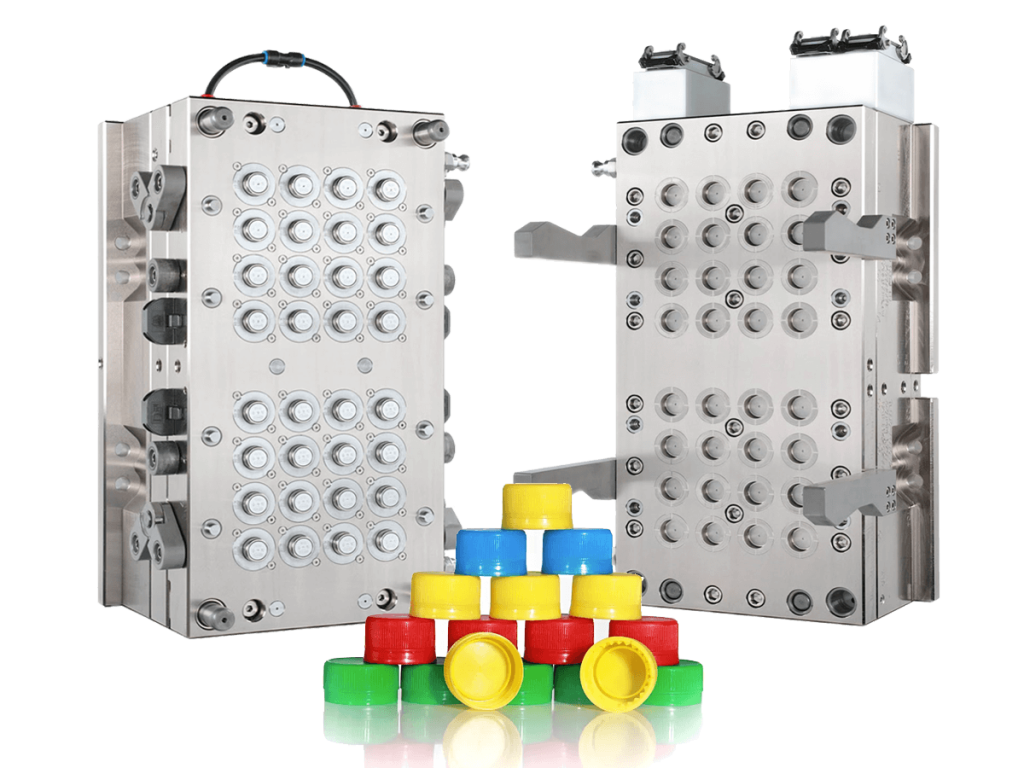

plastic cap mold

cable tie mold

Cable ties (also called cable ties or zip ties) are a type of fastener that is widely used in electronics, electricity, transportation, automobiles and other fields. The most common cable tie consists of a flexible nylon strap with teeth and a hole-shaped head at one end. Once the tail of the cable tie is inserted into the head hole and tightened, it cannot be pulled back. YUCO's main goal is to provide high-quality cable tie molds to the world.

Learn how we can help you overcome your injection mold challenges.

Mold maintenance and life cycle

Proper maintenance is essential to maximize mold performance, ensure consistent part quality, and extend mold life. A comprehensive maintenance program can avoid costly production interruptions and maintain profitability throughout the life of the mold.

Regular cleaning removes plastic residue, mold release agents, and contaminants that can affect part quality. Lubricating moving parts prevents wear and ensures smooth operation. Inspecting critical dimensions and surfaces can detect wear before it affects part quality.

Preventive maintenance involves regular inspection and maintenance of mold components before problems occur. Such a program includes daily cleaning and inspection, weekly lubrication and fine-tuning, monthly detailed inspections, and annual overhauls. The specific schedule depends on production volume, material type, and mold complexity.

Common mold problems and troubleshooting

Flash

Flash is a thin layer of plastic that forms along the parting line and indicates worn shut-off surfaces or excessive injection pressure. Regular inspection and maintenance of parting line surfaces prevents flash formation and its associated part quality issues.

Cooling system blockage

Cooling system blockages can lead to uneven cooling, extended cycle times and part quality issues. Regular flow testing and cleaning of cooling channels maintains optimal heat transfer and avoids costly production issues.

mold steel corrosion

Mold steel can corrode in a variety of ways as it is exposed to extreme environments, cooling systems, and specific chemicals during the molding process. Proactively managing mold corrosion is a long-term investment that pays off by reducing costly repairs, replacements, and production interruptions.

Mold surface wear

Welding techniques and surface treatments can repair worn or damaged mold surfaces. TIG welding with matching materials can repair worn areas and then rework to original specifications. Plating and advanced coatings can significantly extend mold life. For severely worn parts, replacing the part may be more cost-effective than repairing it.

Turn your product ideas into reality

Are you ready to turn your plastic products into reality? YUCO MOLD is a leading injection mold manufacturer in China, providing precision mold solutions that combine quality, speed and cost savings.

We provide full-service from initial design to final production molds:

- Design and engineering - Advanced CAD/CAM software and mold flow analysis to help you optimize your design

- Precision manufacturing - Advanced CNC and EDM equipment to ensure accurate and efficient mold manufacturing

- Quality control - ISO certification system to ensure that each mold meets high-performance standards

- Material selection - Professional knowledge of mold steel and processing processes to meet your specific needs

- Rapid prototyping - Rapid prototype molds to test and verify your design

- Ongoing support - Technical support and maintenance throughout the mold life cycle

Contact us to discuss your project. We are ready to be your trusted mold development partner. We will provide you with: 1. Free design consultation. 2. Project quotation with clear price. 3. Technical feasibility assessment, 4. Timeline and planning support

Tel: +86 13586040750