Flash defects occur when molten plastic escapes from the mold cavity through small gaps or gaps during the injection process. This defect reduces the quality of the molded part and can destroy the mold.

There are many reasons for flash. Therefore, this article discusses the causes, types, solutions and how to prevent injection molding flash.

Whether you are a molding professional looking to optimize the process or a mold designer who wants to better understand injection molding, YUCO hopes to provide you with valuable insights to help you solve one of the most common challenges of injection molding.

What is flash?

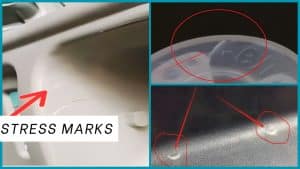

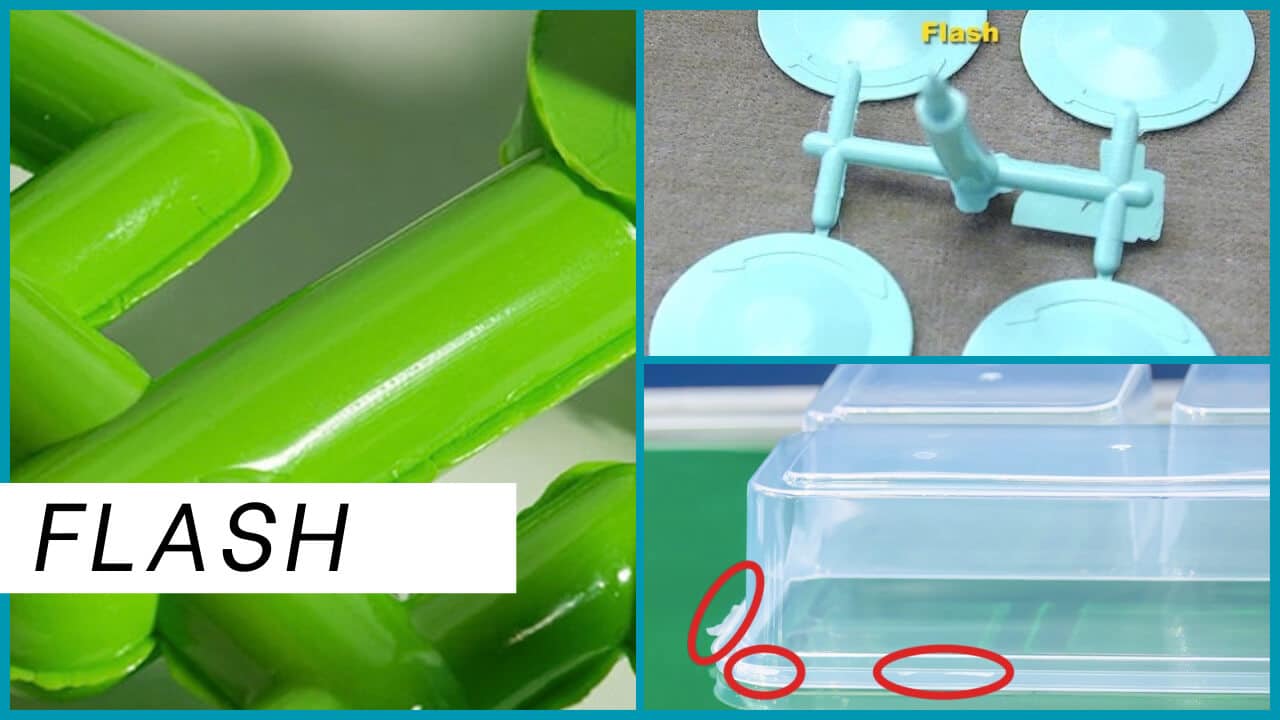

Flash in injection molding refers to thin, often irregular protrusions or fins that form on a molded part. This occurs when molten plastic material escapes from the intended mold cavity through small gaps, voids, or interfaces in the mold.

Flash affects the appearance and functionality of a molded part. This can cause cosmetic defects, affect dimensional accuracy, and compromise the structural integrity of the product. The medical device, consumer goods, and automotive industries are examples of industries with stringent quality standards, so addressing flash is critical. Additionally, flash can indicate deeper issues, such as incorrect machine setup, mold alignment issues, or problems with the material itself.

Types of flash

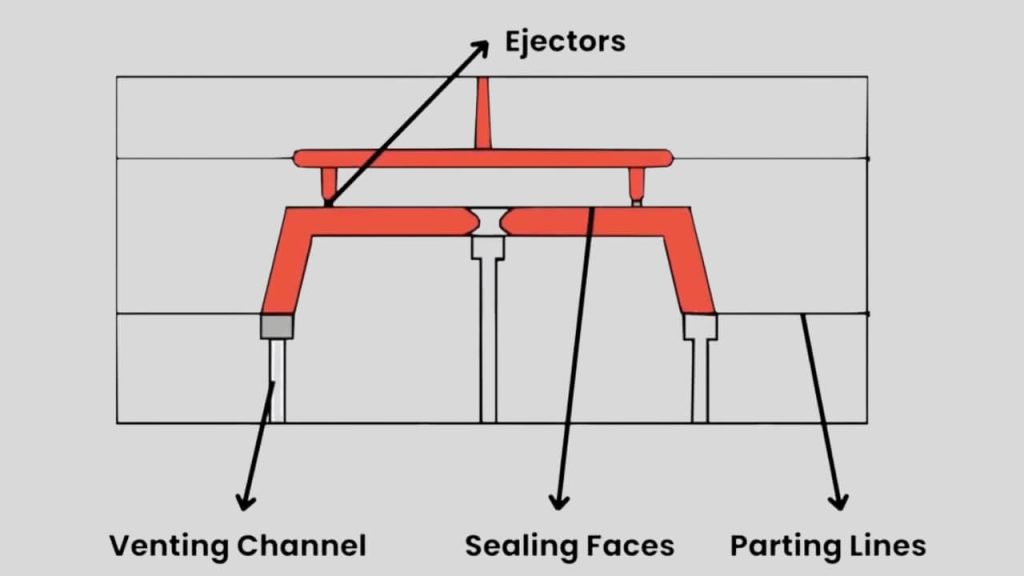

- Parting line flash: Parting line flash is the most common type of flash in injection molding and occurs on the line where the two halves of the mold meet. It typically appears as a thin, protruding film or fin around the perimeter of the molded part.

- Vent flash: Vent flash occurs at the vent location of the mold and looks like a thin, feathery protrusion. While some minimal vent flash is generally considered acceptable, excessive vent flash indicates a problem with the vent design or processing parameters.

- Gate flash: Gate flash appears as excess material around the gate area of the mold cavity. Gate flash can be caused by gate wear, improper gate design, or incorrect processing parameters.

- Flow flash: Flow flash occurs when material squeezes out from between mold components such as cores, inserts, or slides. This type of flash is particularly concerning because it often indicates a more serious problem with mold maintenance or design.

- Ejector flash: Ejector flash forms around the ejector location and is characterized by a small ring or protrusion of excess material. This type of flash indicates a worn or misaligned ejector system.

Understand the causes of flash in injection molding

There are many reasons for flash in plastic injection molding. The interaction between different factors can also make it challenging to find the cause of flash. Here are some things you should be aware of when injection molding your parts:

Mold design issues

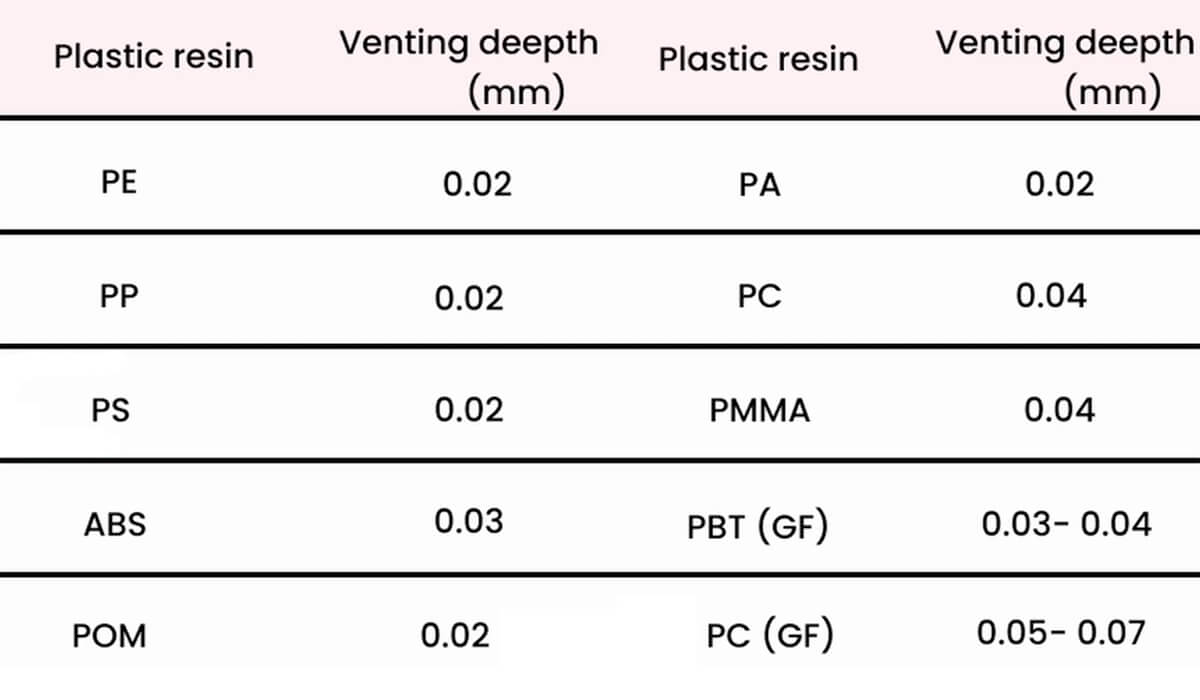

Improper venting

Inadequate or improperly located vents can trap air in the mold cavity. When air cannot escape properly during injection, it can create excessive pressure, forcing material into unwanted areas. Inadequate vent depth or blocked vents can further exacerbate the problem, leading to unpredictable flash and quality issues.

Gate-related issues

The location, size, and design of the gate control how the plastic enters the mold cavity. Improper gate placement can lead to uneven filling, which can create localized high-pressure areas that can cause flash. A worn or incorrectly sized gate may not effectively control material flow, causing flash around the gate area or elsewhere in the mold. A poorly designed gate can cause uneven flow, leading to excess material overflow and flash.

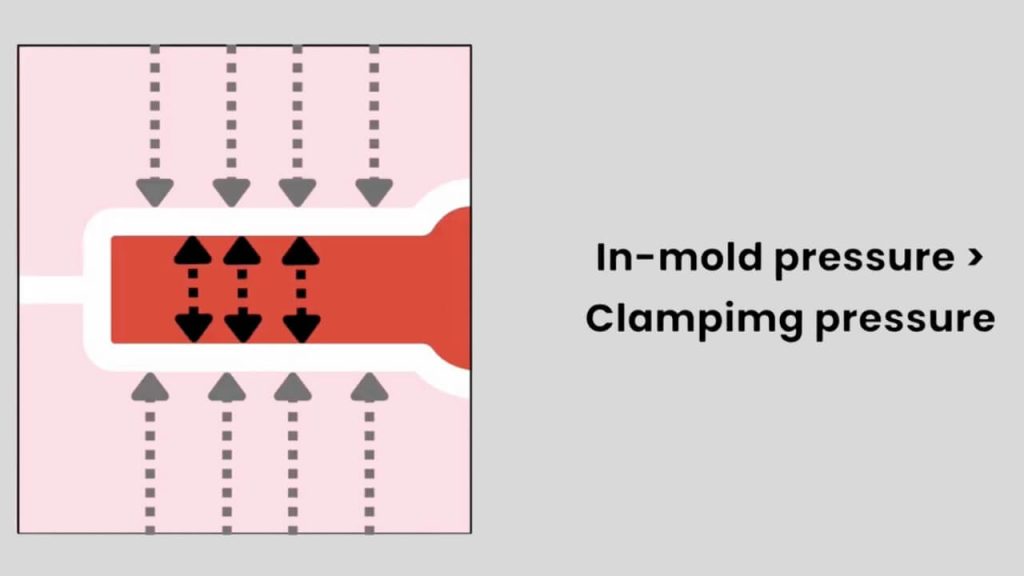

Insufficient clamping force

Flash can occur during the packing process. When the machine’s clamping force cannot adequately counter the internal pressure created during injection, the mold halves may separate slightly, creating a path for material to escape. Clamping pressure must be precise, especially for large parts or high-cavity molds.

Mold temperature

If the mold is too hot, the material cannot solidify quickly enough, resulting in excessive flash. Conversely, if the mold is too cold, the material cannot flow properly, resulting in incomplete fill and defects.

Mold wear and damage

Over time, repeated cycles of high-pressure injection and the abrasive nature of plastic materials cause mold surfaces to wear. This is particularly noticeable at the parting line, where even the smallest amount of wear can create gaps large enough for material to escape. In addition. Environmental contaminants such as dust and debris on the parting line can hold the mold open.

Complex designs

Cavities and other complex features can increase overall stress in the mold and cause leaks and defects in certain areas.

Material-related issues

Viscosity

Viscosity is the flow property of any liquid and is central to the injection molding process. Materials that flow too well can easily penetrate small gaps in the mold. Generally speaking, temperature, material properties, pressure, and speed can all affect this viscosity.

Material degradation

Moisture contamination, thermal degradation from excessive heat, and improper storage can change material properties, which can promote flash formation. Degraded materials can exhibit unexpected flow behavior, making process control more difficult and increasing the likelihood of flash formation.

Material selection issues

Different materials exhibit different flow characteristics, shrinkage, and processing windows. Selecting the wrong material for processing can lead to persistent flash issues.

Process parameter issues

Inconsistent cycle times

Irregular cooling times can affect material solidification patterns, while inconsistent holding times can cause pressure variations that promote flash formation.

Pressure-related issues

Pressure is one of the most common process characteristics that can increase the likelihood of flash. Higher pressures result in higher temperatures and flow characteristics in a closed environment, forcing material into gaps. An incorrect holding profile that does not adequately control material behavior during cooling can lead to flash formation.

Temperature issues

Barrel and nozzle temperatures can also have a direct impact on this. Higher temperatures can make fluids more likely to leak due to lower viscosity, increasing the likelihood of injection flash.

Injection speed issues

High injection speeds can create pressure spikes that force material into unintended areas. Poor speed control or improper speed-pressure conversion during filling can create unstable conditions that promote flash formation.

Overfilling

Any injection molding setup is limited by size and geometry. If the molten plastic is overfilled, the injection pressure will naturally exceed the clamping pressure and cause leakage. This will increase the possibility of flash and other failures.

Conclusion

Understanding and managing flash in injection molding is essential to producing high-quality products. The key to successful flash prevention lies in a comprehensive approach that addresses mold design, material selection, and process control simultaneously.

As a professional injection molding service provider, YUCO MOLD understands the challenges you face when dealing with flash-related issues. Our expertise can help you achieve superior results through:

Expert mold design and manufacturing, flash-free molds.

Process-optimized injection molding services with real-time process monitoring and control

Quality assurance, advanced quality control systems, and comprehensive part inspection services

Contact our team of experts today to discuss how to optimize your injection molding operations. Let us help you achieve flash-free, high-quality injection molded parts that meet your exact specifications.