It takes a great deal of knowledge and skill to ensure that every product produced by the injection molding is a success. Some injection molding errors are unavoidable, annoying, and sometimes very expensive. One of the most common aesthetic defects is flow marks.

This article aims to provide a comprehensive understanding of flow marks in injection molding, explore the causes, and provide practical solutions. By understanding the mechanisms behind flow mark formation and implementing appropriate preventive measures, you can reduce the number of flow mark defects that may occur throughout the injection molding process while minimizing production problems and costs.

Understanding flow marks: characteristics and effects

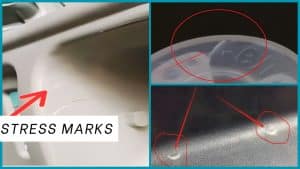

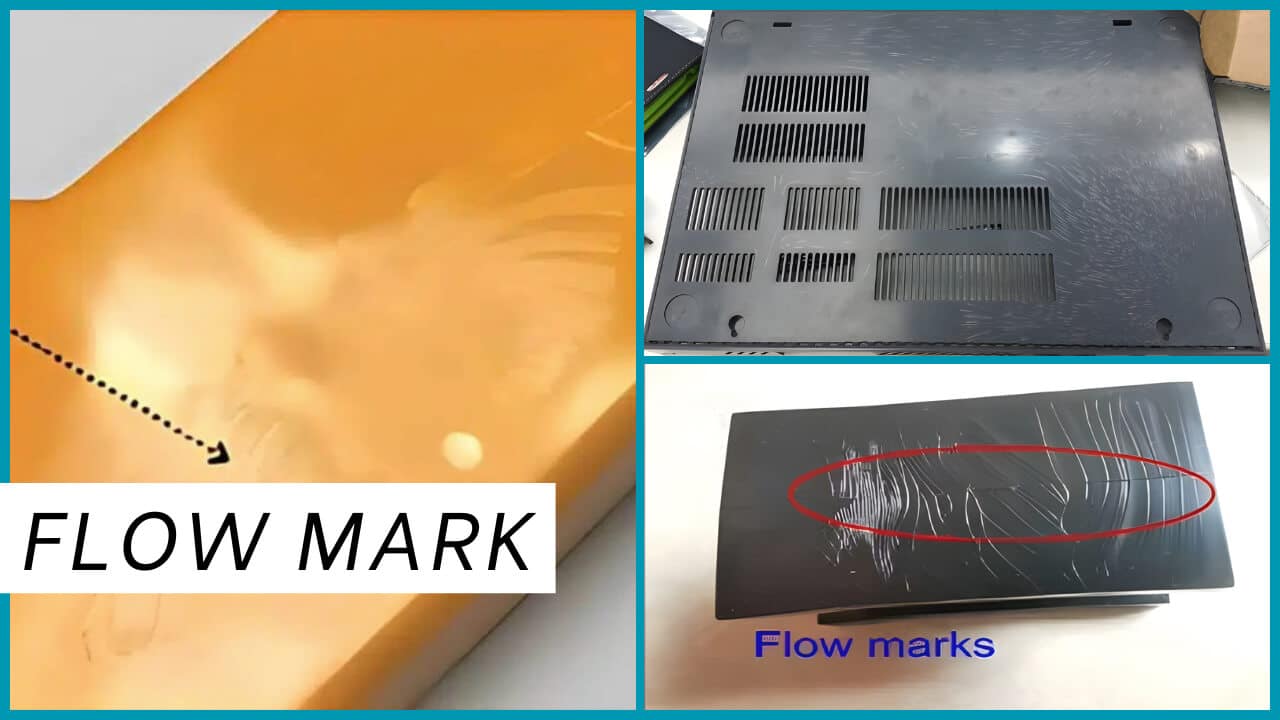

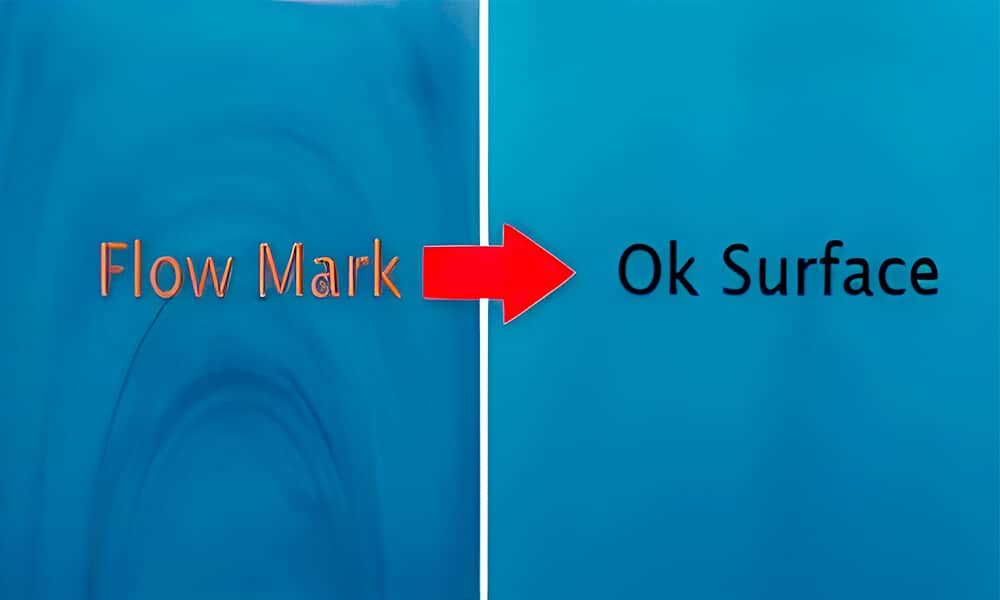

What are flow marks? Flow marks are visible surface defects on injection molded parts that appear as wavy patterns, streaks, or alternating matte and glossy bands. They are also called flow lines. These marks usually follow the path of the plastic flow during the molding process and appear after the product cools. This means that once flow marks occur, there is nothing you can do. The parts will be rejected and sent for recycling.

Flow marks usually appear when the material does not flow evenly during the injection molding stage, such as when there are changes in flow rate, temperature differences, or inconsistent cooling.

While flow marks do not usually affect the structural integrity of the part, they can affect its aesthetics. This is especially important for products that require a perfect surface finish, such as consumer goods and automotive parts.

In addition to aesthetics, severe flow marks may also indicate underlying process problems, such as inconsistent material distribution and wall thickness, and surface irregularities that may affect the fit and assembly of the part. In addition, flow marks may also interfere with painting, coating, or other surface treatment processes.

What causes flow marks?

Flow marks are usually related to materials, process parameters, mold design factors, or injection molding machines. These factors all affect the way the molten material flows into the mold cavity. Each of them can independently cause flow marks, but more often, flow marks are caused by the interaction of multiple factors.

Material factors:

Material type plays a crucial role in flow mark formation. Different materials have their own unique properties, and using low-viscosity materials or materials that are incompatible with the mold can cause flow problems. Materials with high viscosity or that are sensitive to temperature changes are more likely to produce flow marks.

Material degradation is another important factor – when plastic materials are exposed to excessive heat or improper storage conditions, their molecular structure breaks down, resulting in inconsistent flow patterns.

The moisture content in hygroscopic materials can also cause serious quality issues because water molecules can evaporate during processing, causing surface defects.

In addition, additives and colorants can significantly affect flow behavior. Some pigments or additives may not mix properly with the base resin, resulting in inconsistent material flow, which manifests as visible marks on the surface of the part.

Process parameters:

Flow marks can be caused by process parameters in the injection molding manufacturing technology.

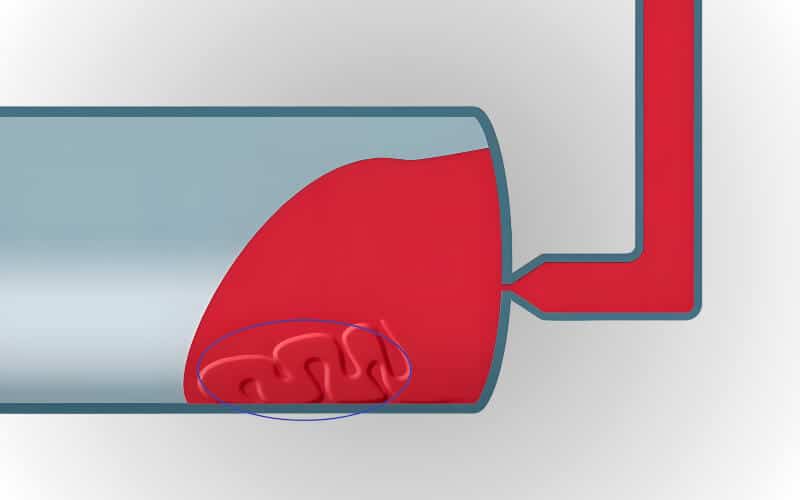

The melt is injected at a rate that ensures that it reaches the mold quickly before losing all the stored heat. If the injection rate is too low, some of the melt will solidify when it reaches the mold. The change in flow pattern will produce flow marks.

The melt injection pressure contributes to melt uniformity. When the injection pressure is sufficient, the flow pattern becomes uniform, which means that flow marks will form when the injection pressure is low.

The melt temperature is a key factor in determining the viscosity of the melt. The main purpose of heating the plastic is to make it flow. Inconsistent or incorrect melting temperature will cause the material to flow irregularly, resulting in visible marks.

The holding stage is crucial to prevent flow marks. Insufficient holding pressure or holding time can cause material shrinkage and surface defects, while excessive pressure can cause other quality problems.

Mold design factors:

Mold design plays a vital role in reducing flow marks.

The location and size of the gate must be carefully considered because they determine how the material enters the cavity and affect the flow pattern. When the gate and runner diameters are too small, melt flow is restricted. Generally speaking, the smaller the channel, the faster the cooling.

Inadequate or improperly located vents can trap air and cause flow disruptions that can create visible marks.

Mold temperature also plays a critical role. Cooling channel design ensures uniform temperature distribution throughout the mold. If mold temperature is too low, the melt may cool too quickly after entering the mold. Flow marks occur when mold components cool too quickly around the gate.

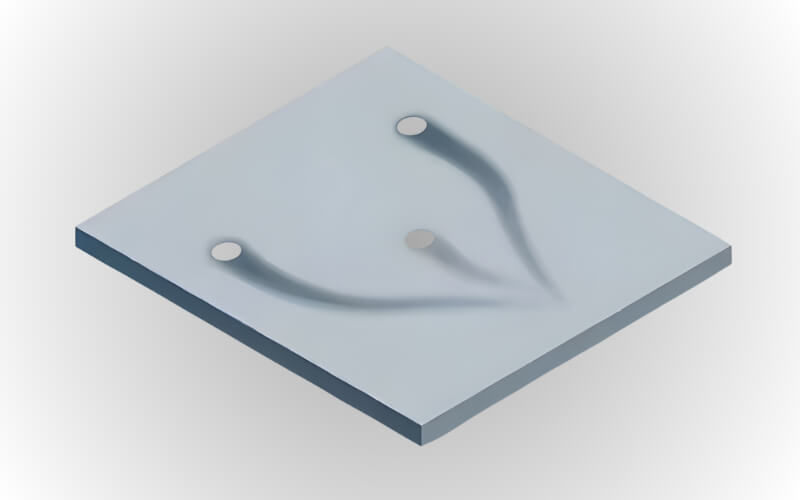

Wall thickness variations in part design can cause flow disruptions as the material attempts to fill areas of varying thickness.

The surface finish of the mold cavity can also affect how the material flows and can cause flow marks to form if not properly maintained.

Factors related to the injection molding machine:

The problem can be caused by the machine settings before the gate is applied. The performance of the injection molding machine directly affects the formation of flow marks.

Insufficient clamping force can cause the mold to open slightly during injection, resulting in inconsistent flow patterns.

Barrel temperature settings must be precisely controlled in all areas to ensure uniform material melting and flow.

Screw speed and back pressure settings affect the plasticization and homogenization of the material – incorrect settings can lead to inconsistent material preparation and subsequent flow marks.

Machine maintenance and condition are also important factors, as worn parts can affect machining consistency and material quality.

Strategies for flow mark prevention and mitigation

Effective flow mark prevention and control requires a comprehensive approach that includes multiple strategies. The following are key points to reduce these defects:

Material selection and preparation

Material selection and proper preparation are fundamental to preventing flow marks. Select polymers with the best flow characteristics to meet your specific application, while implementing a strict drying procedure for hygroscopic materials at the manufacturer’s recommended temperature and time.

When using additives, make sure they are compatible with the base resin and dispersed evenly. Consider flow modifiers or processing aids, if necessary, which can improve the material’s flow characteristics without compromising other properties.

Process parameter optimization

Fine-tuning process parameters are critical to reducing flow marks and generally starts with optimizing injection speed. Injection speed is always proportional to injection pressure. Therefore, increasing the pressure supplied to the screw increases the speed of the melt. Generally, increasing the injection speed allows the material to fill faster and more evenly, reducing the possibility of flow lines. However, the speed must be carefully adjusted to avoid other problems such as flashing

Carefully balance mold and melt temperatures to maintain consistent material flow throughout the cavity. You can increase the melt temperature by changing the barrel temperature setting. When the temperature increases, the melt will flow more easily. However, you need to stay within the temperature range where the plastic decomposes.

In addition to the barrel temperature, the mold temperature can also be increased. Many manufacturers usually pre-cool the mold to help cool the object. However, if this causes the melt to cool prematurely, then consider increasing the mold temperature.

In addition, the longer the melt must travel, the more likely it is to cool. Hot runners can be used when the distance cannot be shortened any further. This will keep the melt warm until it is poured into the mold.

The holding stage is equally important, and the holding pressure and time are adjusted to ensure that the part is properly molded without causing other defects.

Advanced mold design technology

Modern mold design plays a vital role in preventing flow marks. Utilize computer-aided mold flow analysis to optimize gate location and size.

Use complex cooling channel designs, such as conformal cooling, to maintain an even temperature distribution throughout the mold.

Consider surface treatment or coating the mold cavity to reduce friction and improve material flow.

Sharp edges in the mold design can cause uneven flow patterns. If possible, rounding these corners or designing parts with uniform wall thickness will reduce the impact of changes in flow direction.

For complex parts, consider advanced molding technologies such as gas-assisted injection molding or sequential valve gating.

Equipment maintenance and upgrades

Regular maintenance and equipment updates are essential for consistent production quality. Develop and follow a comprehensive maintenance schedule for all machine components, especially those that affect material plasticization and injection control. Consider upgrading to a modern injection molding machine with an advanced control system to provide better process monitoring and control capabilities. Regular calibration of temperature sensors, pressure sensors, and other critical components ensures accurate process control.

Training and best practices

Train operators and quality control personnel to recognize the early signs of flow marks and understand their potential causes. Develop and implement standard operating procedures that cover material handling, machine setup, and process monitoring.

Conclusion

Flow marks in injection molding are always avoidable. Flow marks can be effectively managed and reduced if prevention strategies are properly understood and implemented. As discussed in this article by YUCO MOLD, successful flow mark prevention requires a multifaceted approach.

As a leading injection molding solutions provider in China, our company has decades of expertise in addressing complex manufacturing challenges, including flow mark prevention and control. Our strengths include:

- Advanced technical capabilities: advanced injection molding equipment with precision control systems, material selection capabilities, and expertise in complex mold design and manufacturing

- Experience: a strong focus on continuous improvement and innovation, with extensive experience in solving challenging injection molding problems

- Quality assurance: strict quality control procedures at every stage of production

- Customer support: a responsive technical support team ensures comprehensive project management services

By working with our company, you are not only talking to a plastic mold maker, but also getting a complete injection molding solution. Our comprehensive approach to flow mark prevention and quality control ensures that your products meet the most stringent quality requirements while remaining cost-effective. Contact us today, our team is ready to help you.